Rail mounting device and method for fixing rails to reinforced concrete railway sleeper

A technology for reinforcing concrete and installing devices, which is applied in the direction of fixing rails, rail fixers, railway fixing devices, etc., can solve the problems of increased cost, expensive manufacturing of rail clips, and the need for substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

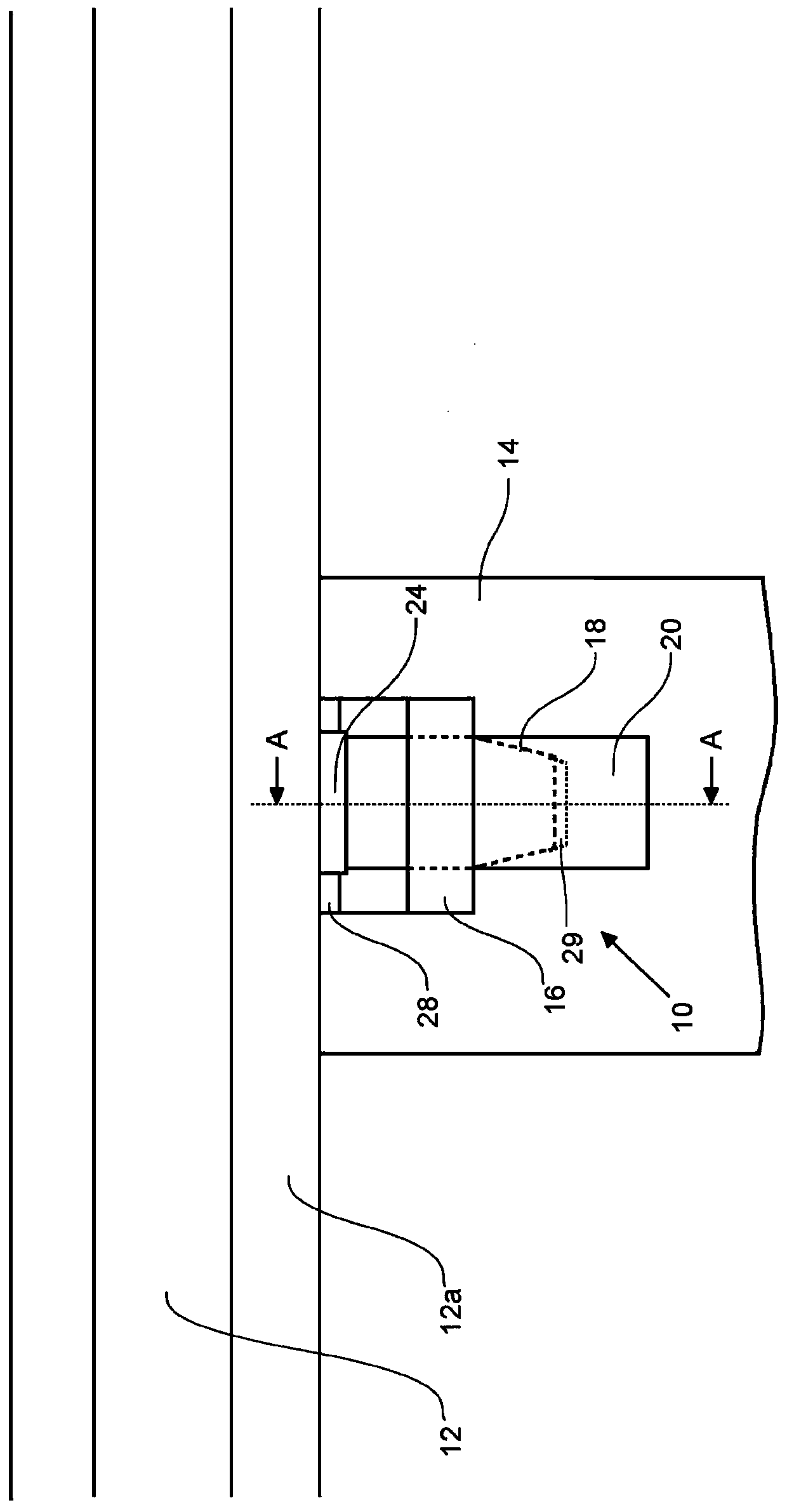

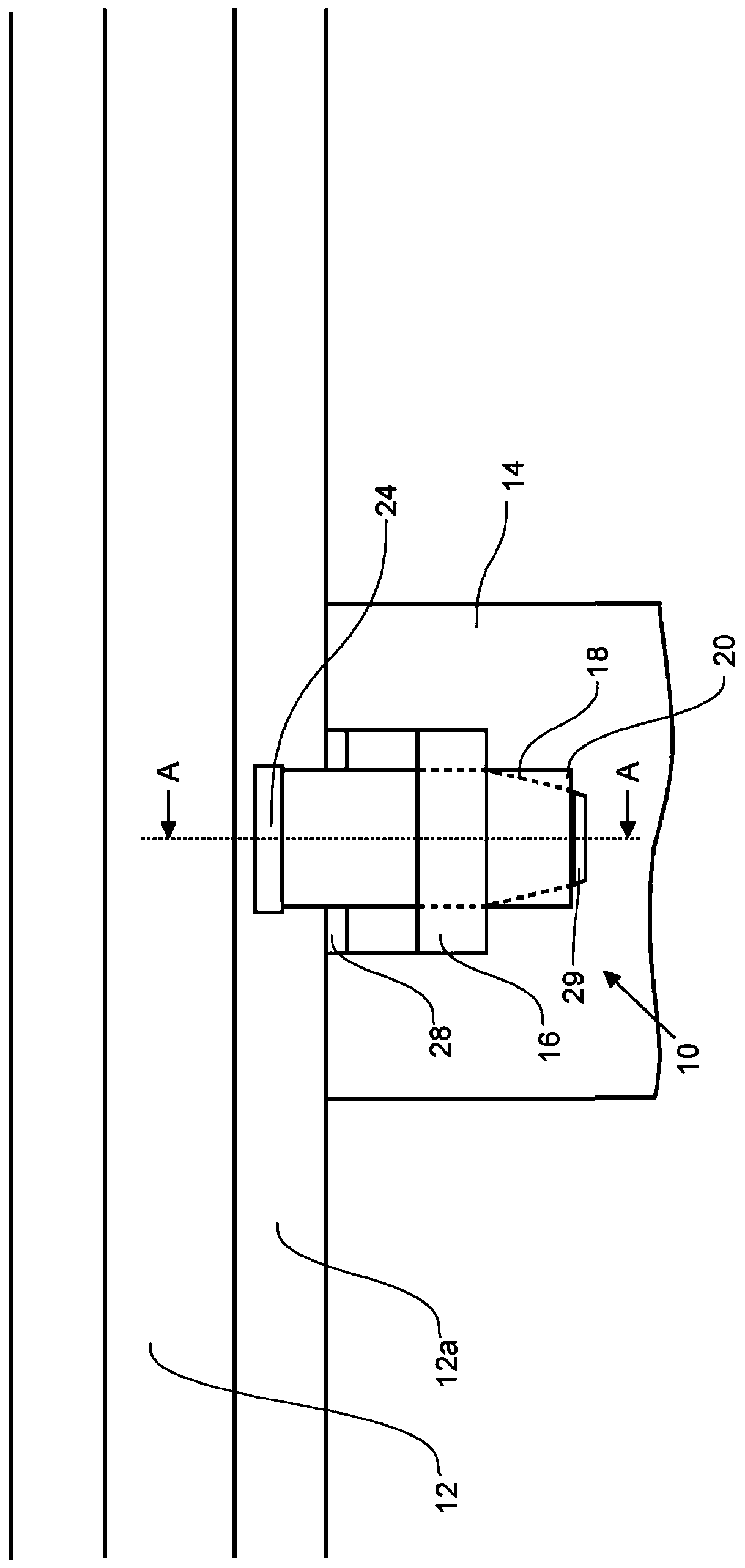

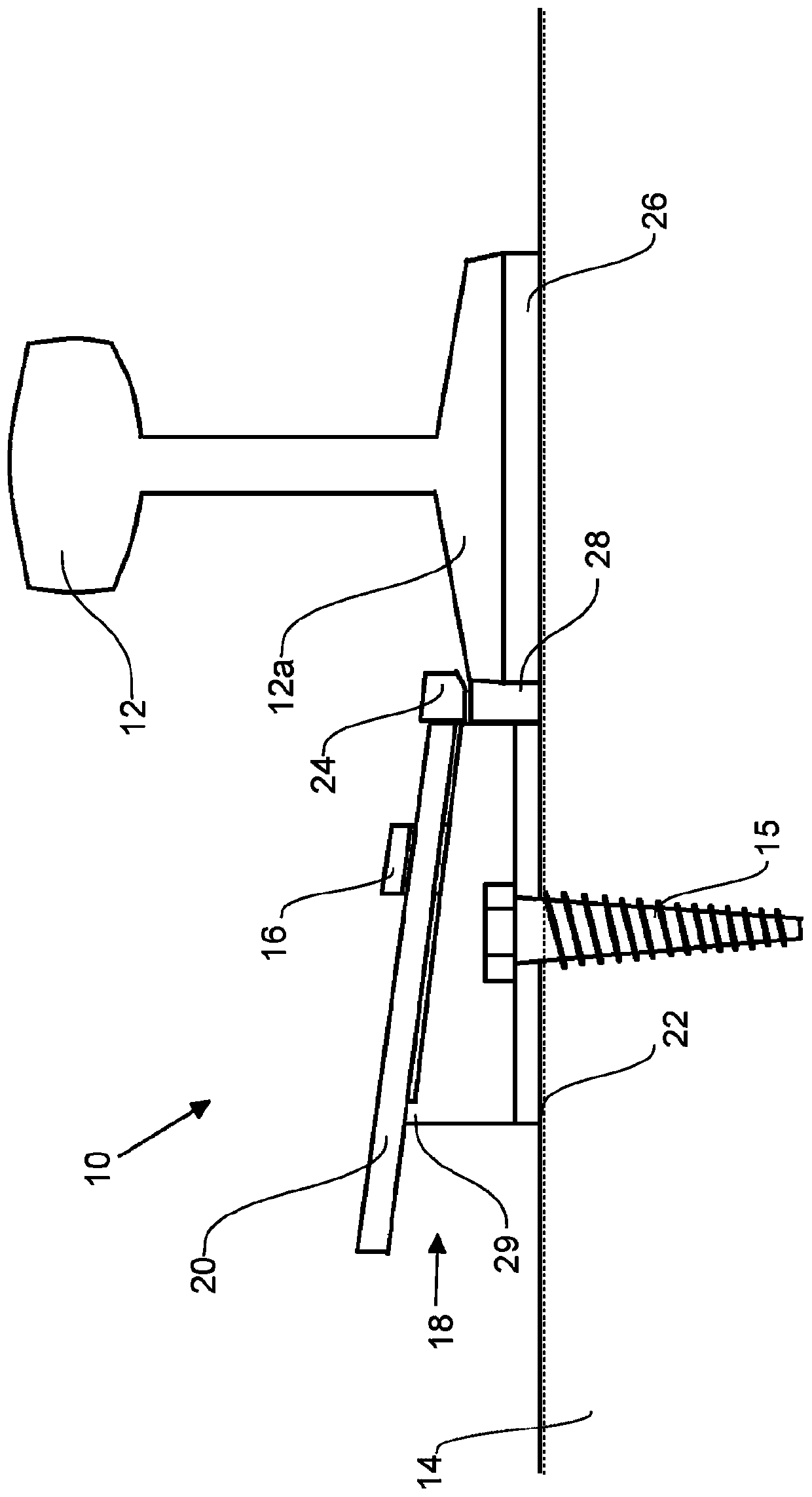

[0024] Figure 1a and 1b is a schematic top view of a preferred embodiment of a rail mounting device 10 according to the present invention. For clarity, those parts that would otherwise be covered in the top view are in the Figure 1a and 1b Shown in dotted line.

[0025] The rail mounting device 10 is used to secure a railroad rail 12 directly or indirectly to a reinforced concrete sleeper. In this description, indirect fixation is understood to mean that a spacer such as an electrically insulating plate is positioned between the guide rail 12 and the reinforced concrete sleeper 14 such that the guide rail 12 and the reinforced concrete sleeper 14 do not come into direct contact with each other. Direct fixation is understood to be the case when there is direct contact between the guide rail 12 and the reinforced concrete sleeper 14 . The device 10 has a first state when the guide rail 12 is not fixed, and has a second state when the guide rail is fixed, and the first and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com