Train track flaw detection wheel assembly tool and method for assembling train track flaw detection wheels

A technology for assembling tooling and trains, which is applied in the field of assembling tooling for flaw detection wheels on train tracks, can solve the problems of high labor intensity for workers, difficulty in installing flaw detection wheels, and high physical exertion, so as to solve locking and adjustment problems, improve convenience and Adjustability, easy promotion and application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. the embodiment.

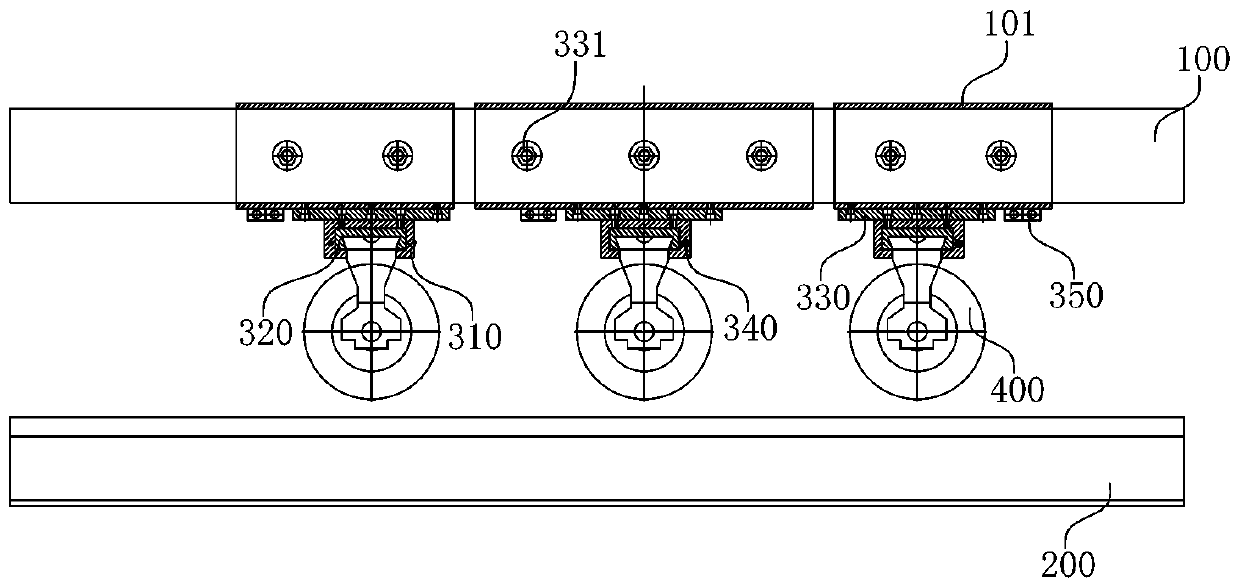

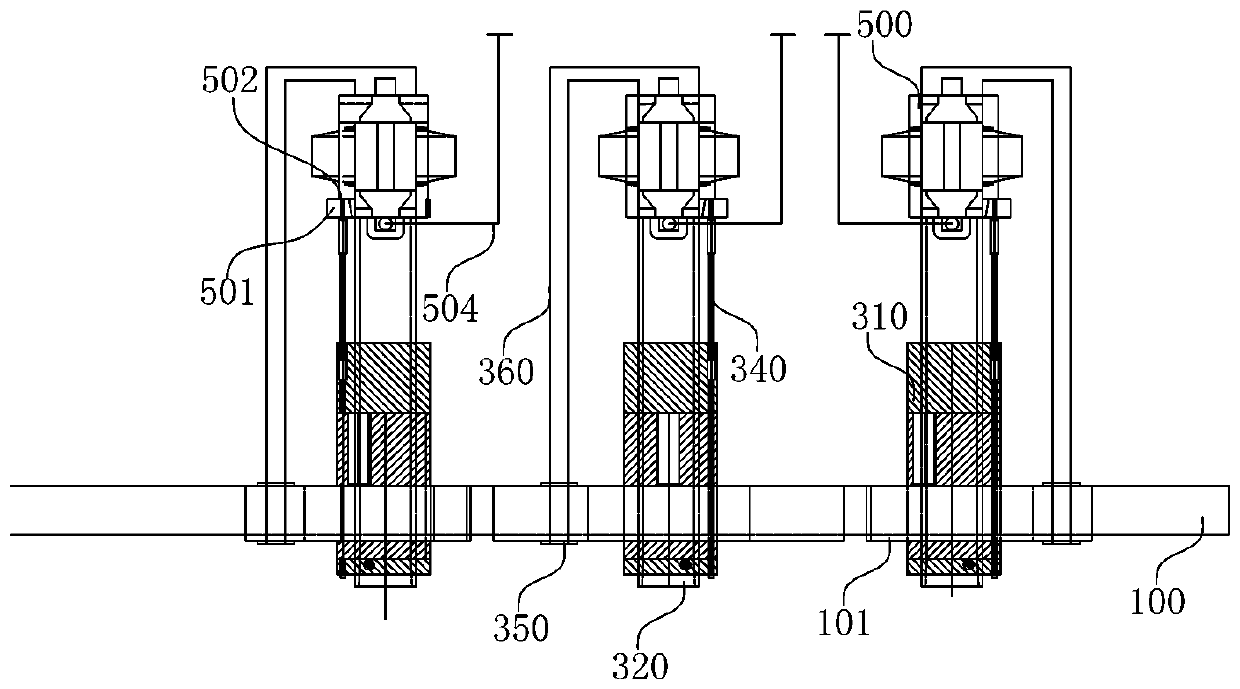

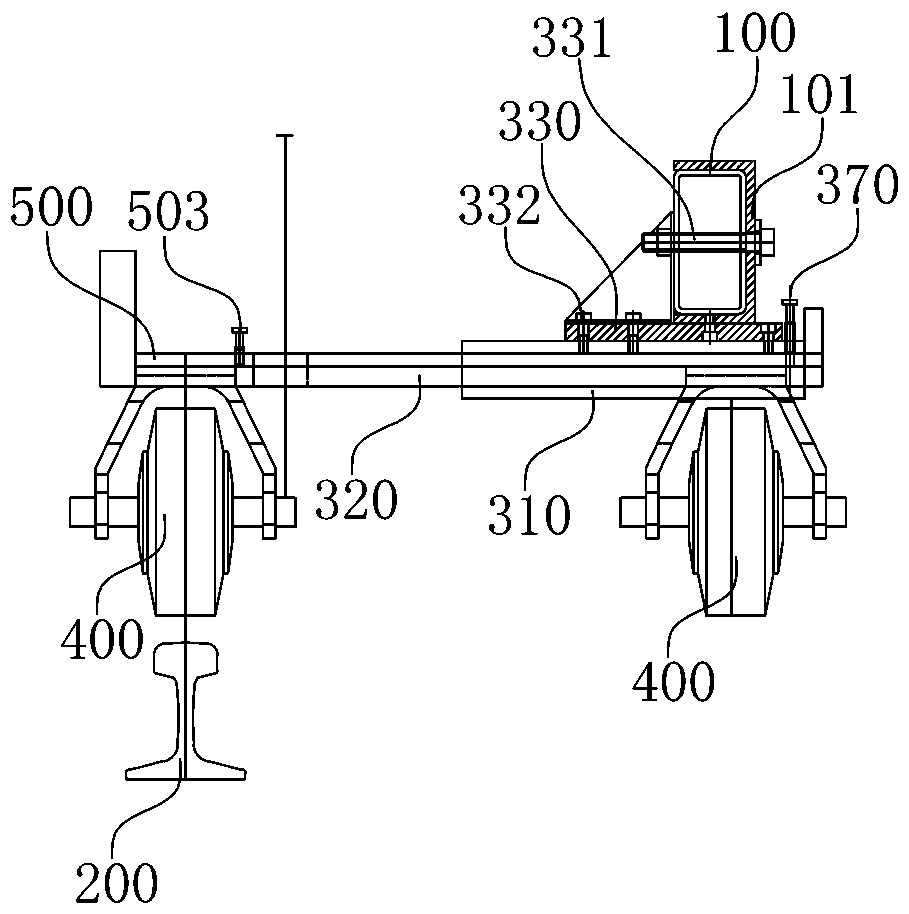

[0036] see Figure 1-Figure 3 , a train track flaw detection wheel assembly tool, used to assemble the flaw detection wheel 400 in the installation groove 500, including the guide groove 320, the guide groove 320 is arranged on the outside of the train, and the outside of some trains is provided with installation space for direct installation. When the installation conditions do not exist, the installation is carried out by setting the installation frame. In this embodiment, a square pipe 100 is arranged on the outside of the train, and a channel steel bracket 101 is fixedly arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com