Driving control method and driving control device for loom

A loom, rotary drive technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as weak beating force, no rise of the main shaft, and thick and thin sections, so as to prevent insufficient beating force and reduce load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

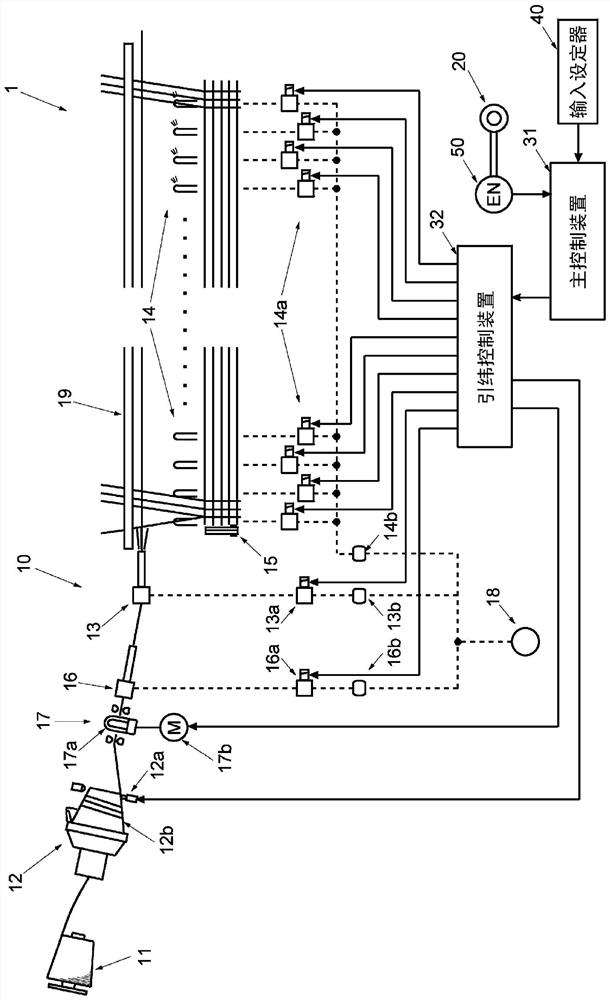

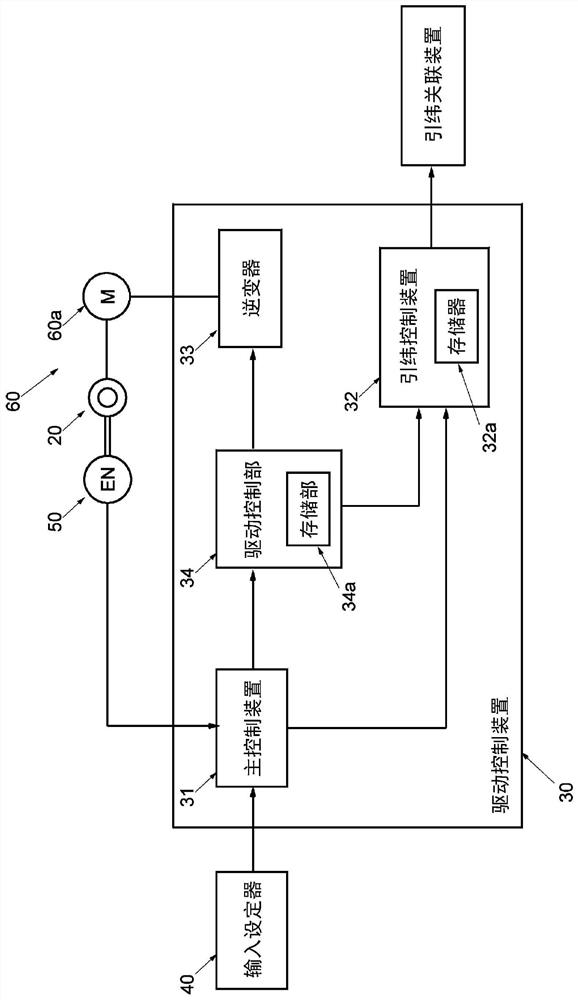

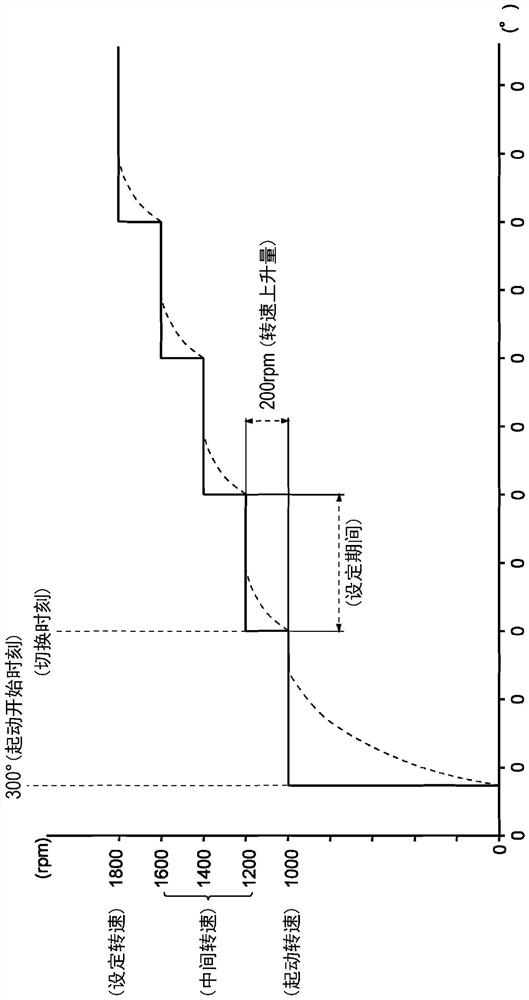

[0063] Below, based on Figure 1~3 An example of the present invention will be described. However, in this embodiment, the present invention will be described by taking an air jet loom as an example of a loom as a premise.

[0064] Such as figure 1 As shown, in the air jet loom 1, the weft insertion device 10 includes a yarn supply body 11, a length-measuring storage device 12 that only stores the weft yarn drawn from the yarn supply body 11 for a length corresponding to the weft insertion length, and is used for The main nozzle 13 for inserting the weft yarn, the plurality of sub-nozzles 14 for assisting the flight of the weft yarn injected from the main nozzle 13, and the yarn supply cutter 15 for cutting the inserted weft yarn. In addition, in the illustrated example, the weft insertion device 10 includes an auxiliary main nozzle 16 provided on the upstream side of the main nozzle 13 to assist the weft insertion of the main nozzle 13, and a weft yarn for applying a brakin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap