Contact surface bidirectional shear test device

A test device, two-way shearing technology, applied in the direction of measuring device, using a stable shear force to test the strength of materials, instruments, etc., can solve the problems of the two-way shear test device that has not been reported in the contact surface, and achieve the structure of the device simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

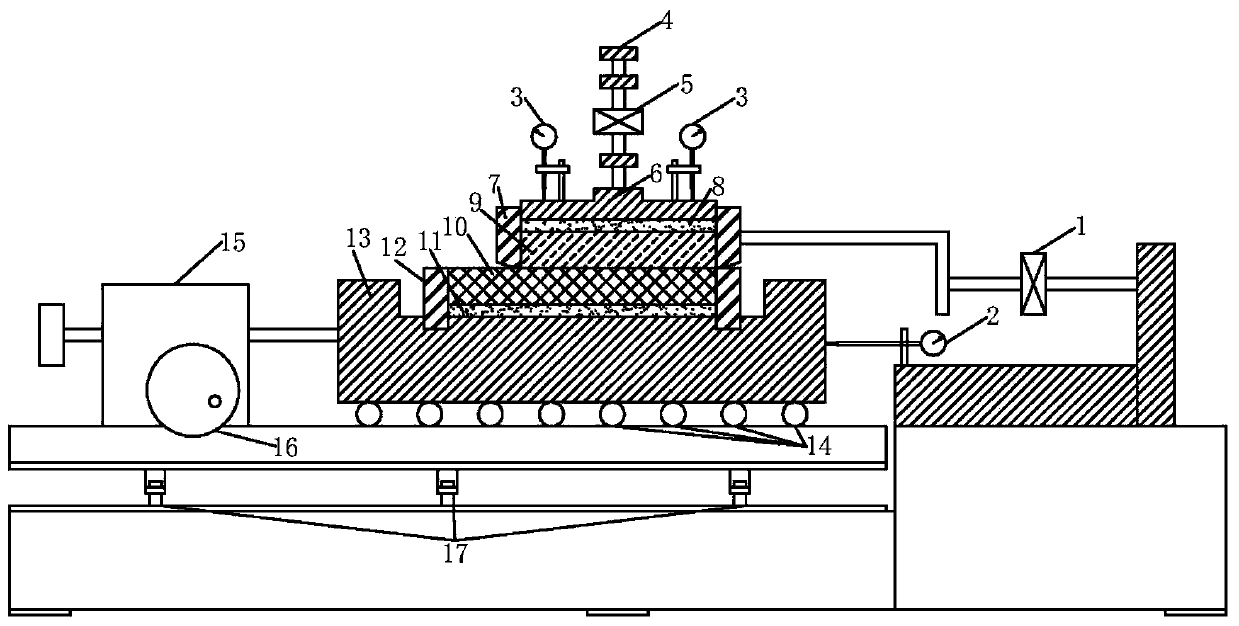

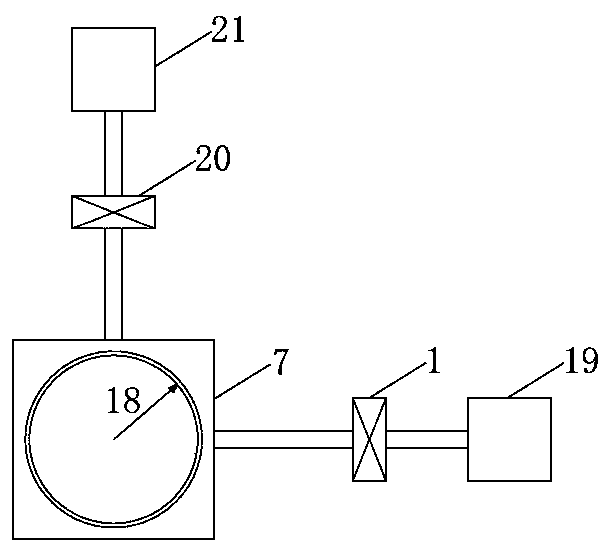

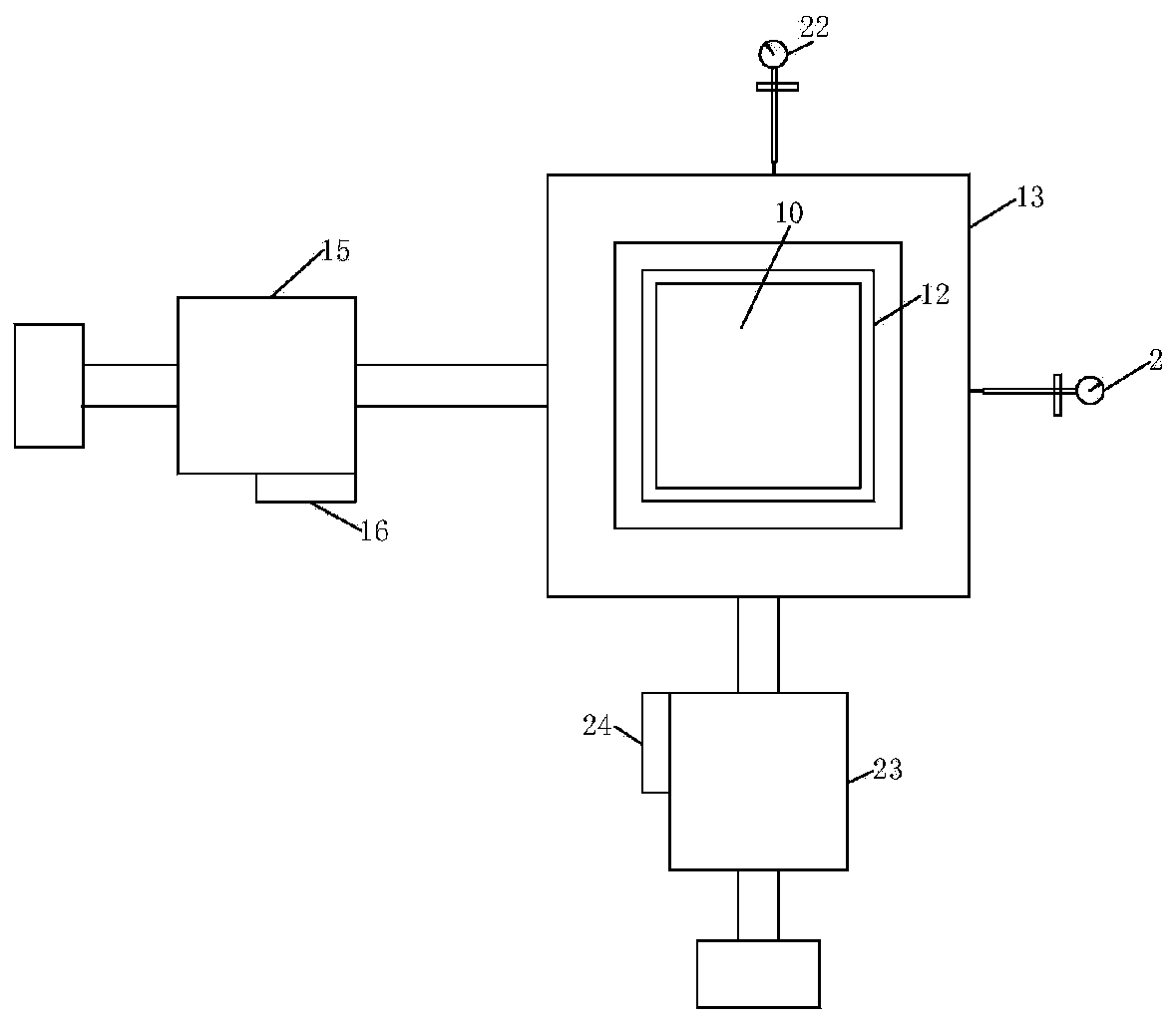

[0038] The technical solution of the present invention will be further elaborated below in conjunction with the description of the drawings and specific embodiments.

[0039] Such as Figure 1~3 The shown test device includes an upper shear box 7, a lower shear box 12, a normal pressure device 4, an X-direction shear transmission device 16, a Y-direction shear transmission device 24, an X-direction push device 15, and a Y-direction push device 15. Pushing device 23, X / Y direction moving device and data acquisition device. The X / Y direction moving device includes X guide rail and Y guide rail. The data acquisition device includes an X-direction force sensor 1 , a Y-direction force sensor 20 , an X-direction displacement sensor 2 , a Y-direction displacement sensor 22 , a normal displacement sensor 3 and a normal force sensor 5 .

[0040] The upper shear box 7 and the lower shear box 12 respectively contain the samples 9 and 10 to be tested for the contact surface test; in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com