A food labeling assembly line

An assembly line and food technology, applied in food forming, food science, application, etc., can solve the problems of unhygienic, damaged food to be worn, and difficult to apply to food of different specifications, so as to reduce the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

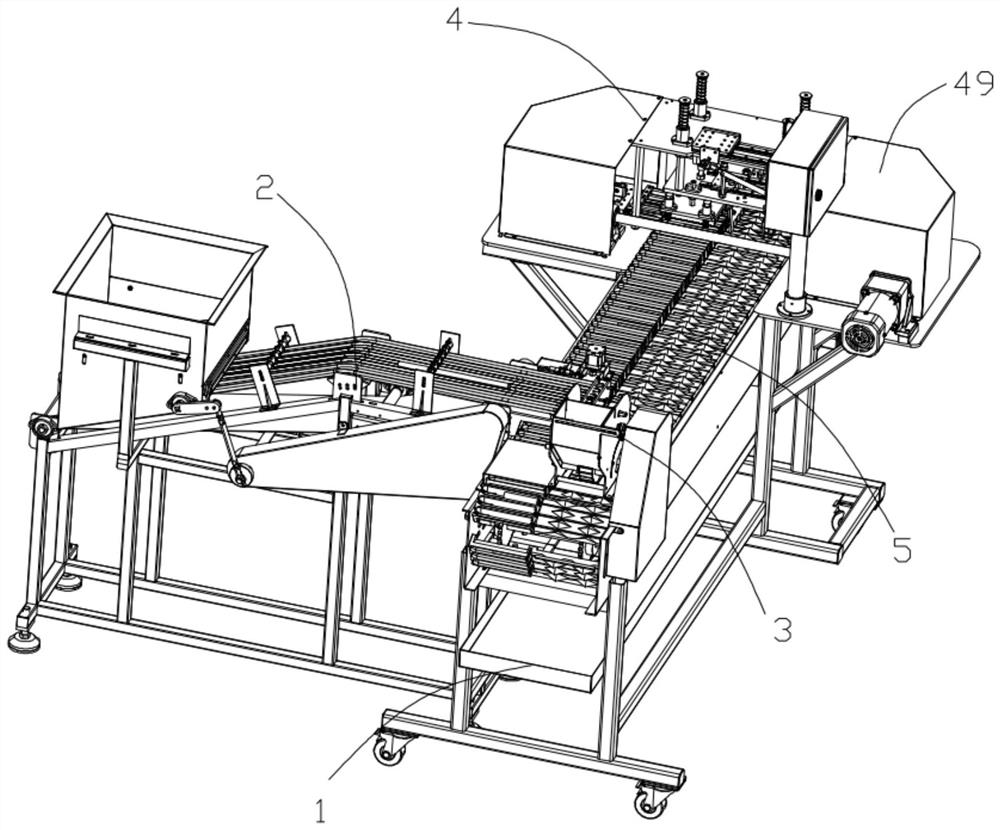

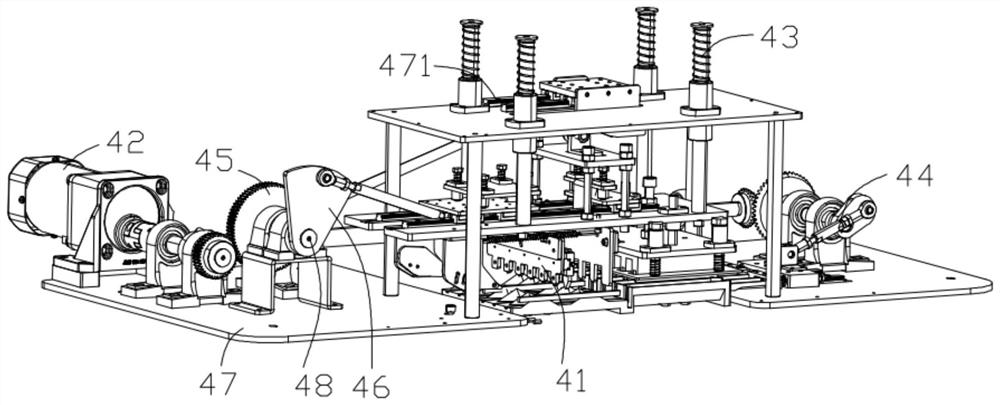

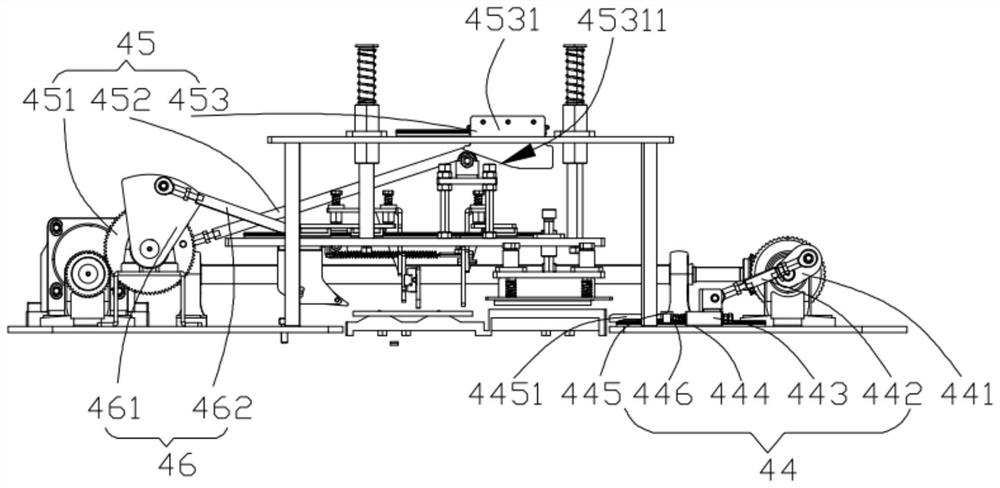

[0041] Refer to attached Figure 1-13 , this implementation includes: frame I1, feeding device 2, lottery dropping device 3, lottery threading device 4, mold 5, conveyor belt I, conveyor belt I is installed on frame I1, mold 5 is fixed on conveyor belt I, mold 5 There is a bamboo stick guide groove 51 and a material trough 52 communicating with the bamboo stick guide groove 51, the material trough 52 and the bamboo stick guide groove 51 are respectively located on both sides of the conveyor belt I, and the sign dropping device 3 installed on the frame I1 is located on the bamboo stick The top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com