An atomizing nozzle with automatic switching of high and low pressure

A technology of automatic switching and atomizing nozzles, which is applied to the spraying device, spraying device, liquid spraying device and other directions with movable outlets, which can solve the problems that the high pressure and low pressure instability of the desuperheating medium cannot be perfectly solved, so as to improve the intelligence of the equipment , saving production costs, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

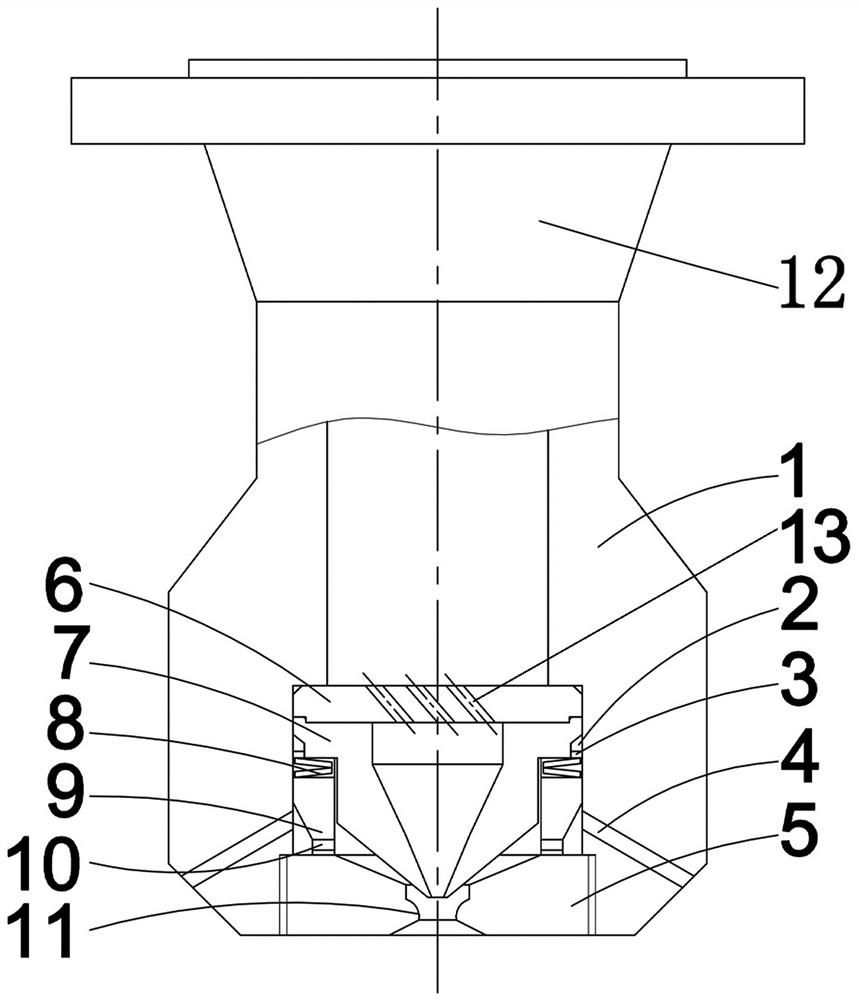

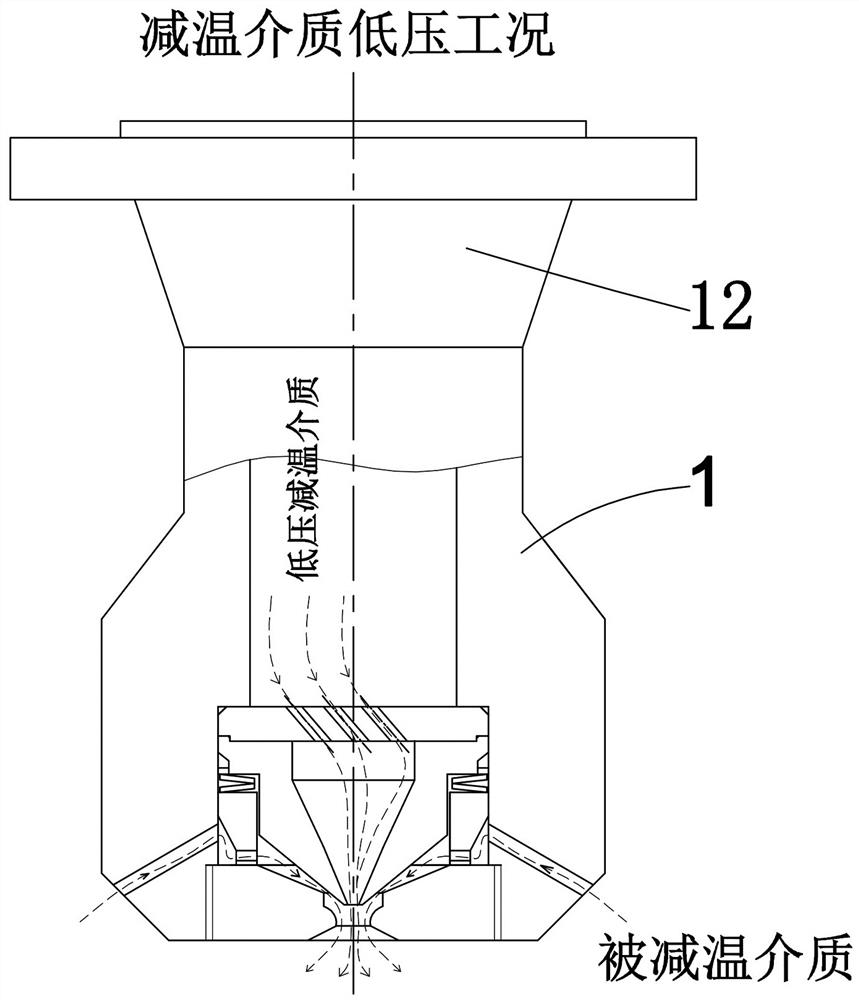

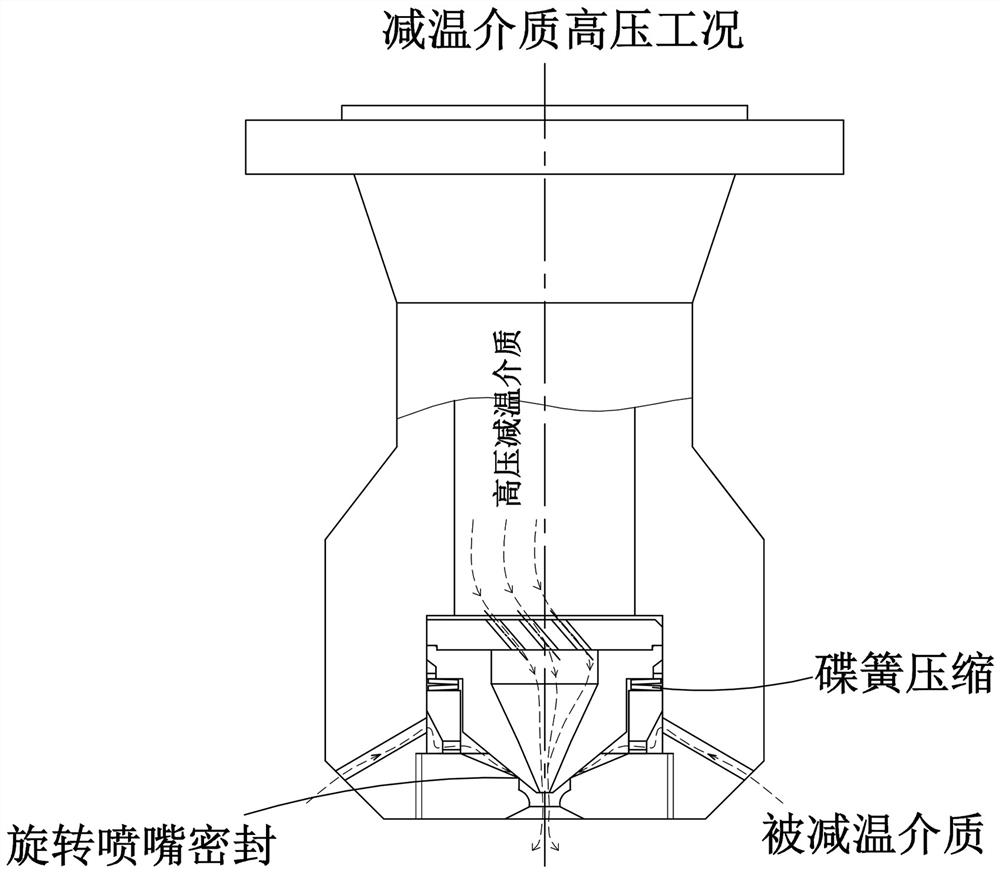

[0029] Refer to attached Figure 1~5 , the high and low pressure automatic switching atomizing nozzle of the present invention includes a housing 1, a rotating nozzle 7, a disc spring 8 and a mixing nozzle 5; the mixing nozzle 5 is threadedly connected to the front end of the housing 1; Cavity 11; the front end of the rotating nozzle 7 is inserted into the middle of the mixing nozzle 5; a spacer 9 is provided at the top of the mixing nozzle 5; the rotating nozzle 7 is provided with a rotating cavity 7-1, and the end of the rotating cavity 7-1 is There is a conical flow channel 7-3 that runs through the rotary nozzle 7; the bottom side of the rotary nozzle 7 is provided with a sealing slope A 7-2, and the front side of the rotary nozzle 7 is provided with a sealing slope B 7-4; A spacer 9 is provided between the side and the mixing nozzle 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com