Alcohol soluble resin, preparation method and method for preparing inhalator spray paint with the same

An alcohol-soluble resin and aerosol technology, applied in the field of painting, can solve the problems of inability to use aerosol painting, and achieve the effect of meeting performance requirements, ensuring stable storage and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

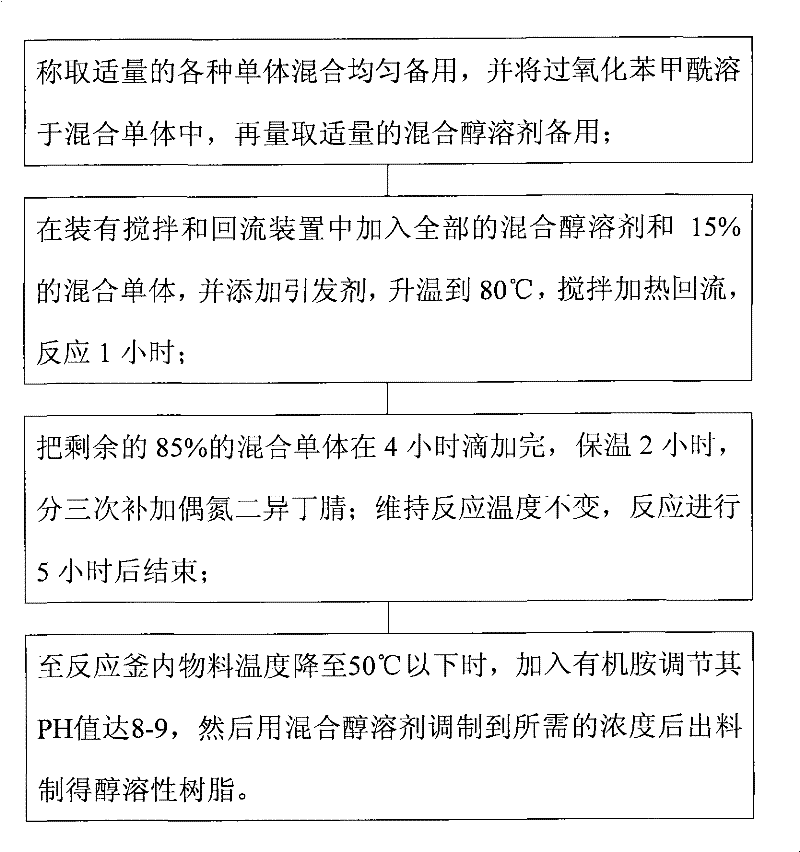

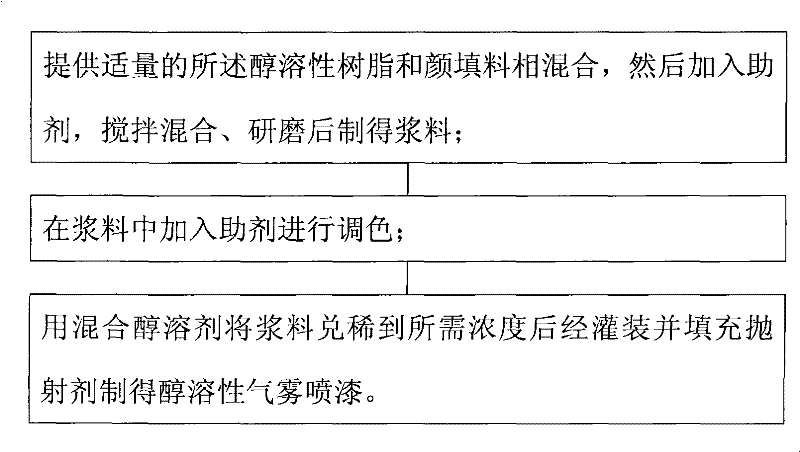

[0033] Second, the preparation method of alcohol-soluble resin, see figure 1 , including the following steps:

[0034] Step 1: Weigh an appropriate amount of various monomers and mix them evenly for later use, dissolve benzoyl peroxide in the mixed monomers, and then measure an appropriate amount of mixed alcohol solvent for later use;

[0035] Step 2: Add all the mixed alcohol solvent and 10%-15% mixed monomer in a device equipped with stirring and reflux (for example: a four-necked flask), and add an initiator, heat up to 80°C-85°C, and stir Heating to reflux, reacting for 1-2 hours;

[0036] Step 3: Add the remaining 85%-90% of the mixed monomer dropwise in 4-5 hours, keep warm for 2-3 hours, and add azobisisobutyronitrile three times; keep the reaction temperature constant, and the reaction is carried out for 5 - end after 6 hours;

[0037] Step 4: When the temperature of the material in the reactor drops below 50°C, add an organic amine to adjust its pH value to 8-9, t...

Embodiment 1

[0055]Embodiment 1: Weigh raw materials according to the following proportions: A component (mixed monomer): 30 kilograms of methyl methacrylate, 22 kilograms of 2-ethylhexyl methacrylate, 15 kilograms of vinyl acetate, methacrylic acid - 25 kg of beta-hydroxypropyl ester, 8 kg of methacrylic acid. Component B (initiator): 0.6 kg of benzoyl peroxide. Component C (mixed alcohol solvent): 45 kg of ethanol, 35 kg of isopropanol. Component D: 0.2 kg of azobisisobutyronitrile, 5 kg of isopropanol, and dissolve azobisisobutyronitrile in isopropanol. Component E: 0.5 kg of triethanolamine. The preparation steps are as follows: Mix 30 kg of methyl methacrylate, 22 kg of 2-ethylhexyl methacrylate, 15 kg of vinyl acetate, 25 kg of β-hydroxypropyl methacrylate, and 8 kg of methacrylic acid , then 0.6 kilograms of benzoyl peroxide are dissolved in the mixed monomer; 45 kilograms of ethanol and 35 kilograms of isopropanol are added in a device equipped with stirring and reflux, then the...

Embodiment 2

[0056] Embodiment 2: A component (mixed monomer): 33 kilograms of methyl methacrylate, 14 kilograms of isooctyl acrylate, 15 kilograms of methylol methacrylate, 17 kilograms of vinyl acetate, 15 kilograms of N-methylolacrylamide kg, 6 kg of itaconic acid. Component B (initiator): 0.6 kg of benzoyl peroxide. Component C (mixed alcohol solvent): 38 kg of ethanol, 42 kg of isopropanol. Component D: 0.2 kg of azobisisobutyronitrile, 5 kg of n-butanol, and dissolve azobisisobutyronitrile in n-butanol. Component E: 0.5 kg of triethanolamine. Its preparation steps are with above-mentioned embodiment 1.

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com