Mineral unmanned inspection robot

A technology for inspection robots and mines, applied in the field of inspection robots, can solve the problems of hindering the movement of inspection robots, heavy burden on driving parts, inconvenient detection, etc., and achieves the effect of convenient climbing, improved lubrication effect, and convenient lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

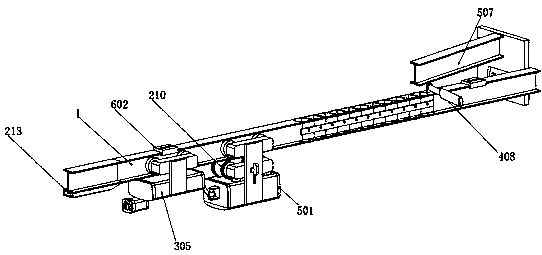

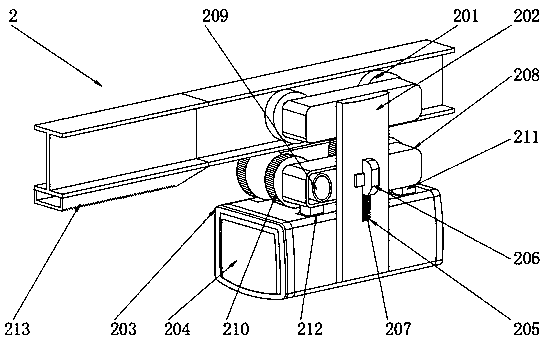

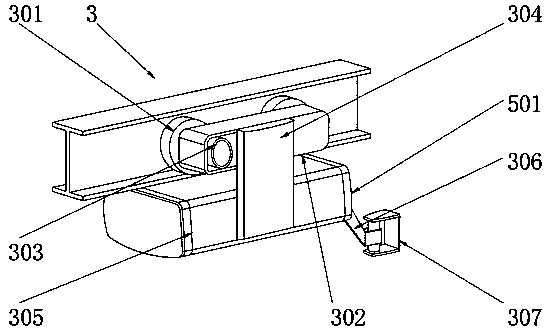

[0042] Example: such as Figure 1-8 As shown, the present invention provides a technical solution. The mining unmanned inspection robot includes a guide rail 1, a climbing assembly 2 is installed in the middle of the guide rail 1, and the climbing assembly 2 includes a driven wheel 201, a first connecting plate 202, a battery box 203 , storage battery 204 , guide opening 205 , slide block 206 , spring 207 , first motor box 208 , first motor 209 , first driving wheel 210 , terminal post 211 , wiring tube 212 and backing plate 213 .

[0043]Four driven wheels 201 are installed on both sides of the guide rail 1 respectively, and two adjacent driven wheels 201 are respectively installed on both ends of the first connecting plate 202, the bottom end of the first connecting plate 202 is connected with a battery box 203, and the inside of the battery box 203 is installed with Storage battery 204, first connecting plate 202 middle part is provided with guide port 205, and guide port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com