Injection mold achieving in-mold automatic blanking

An injection mold and automatic technology, applied in the field of injection mold, can solve the problem of low efficiency of automatic material cutting, achieve the effect of simple structure, unaffected appearance and function, and reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

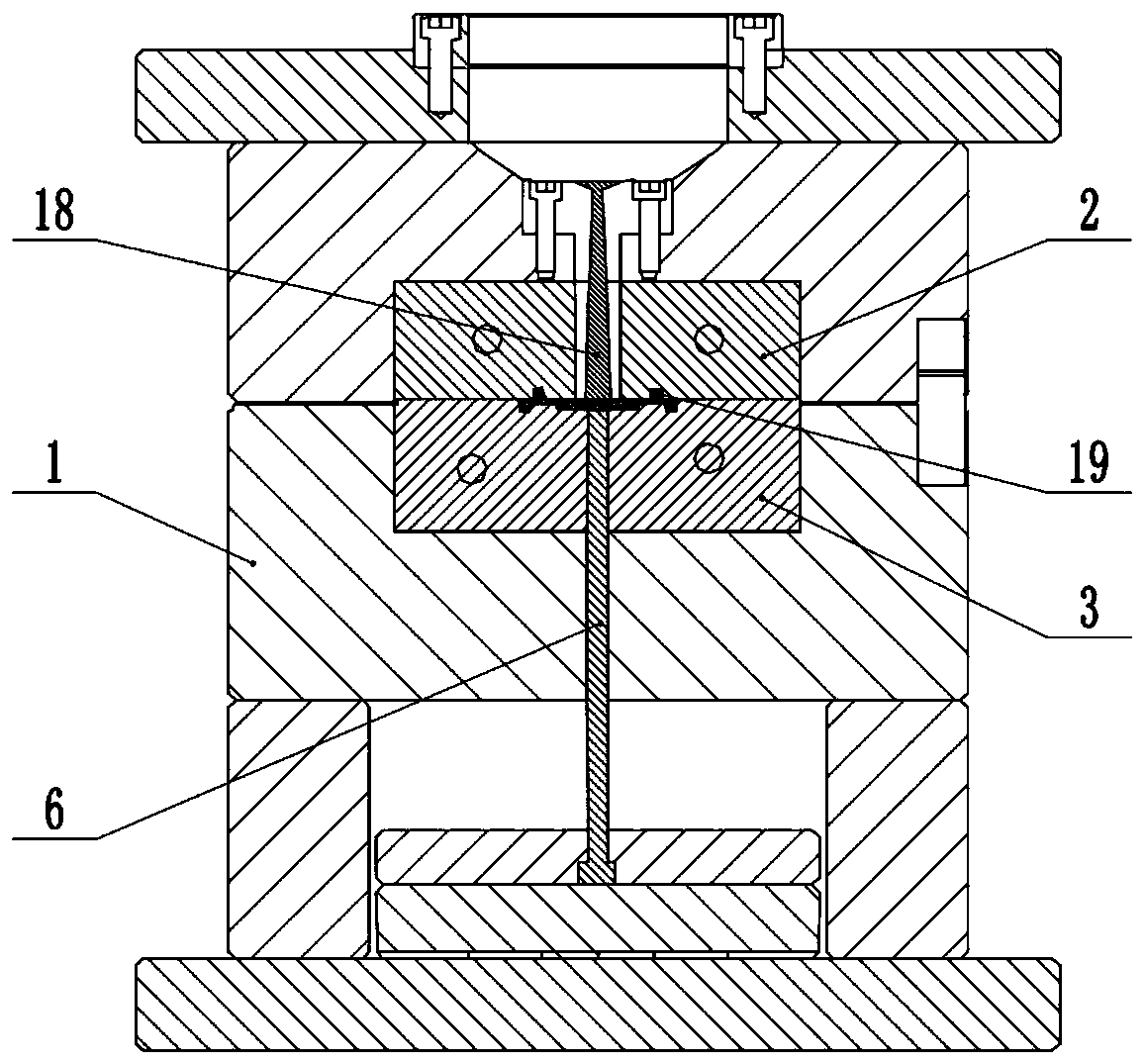

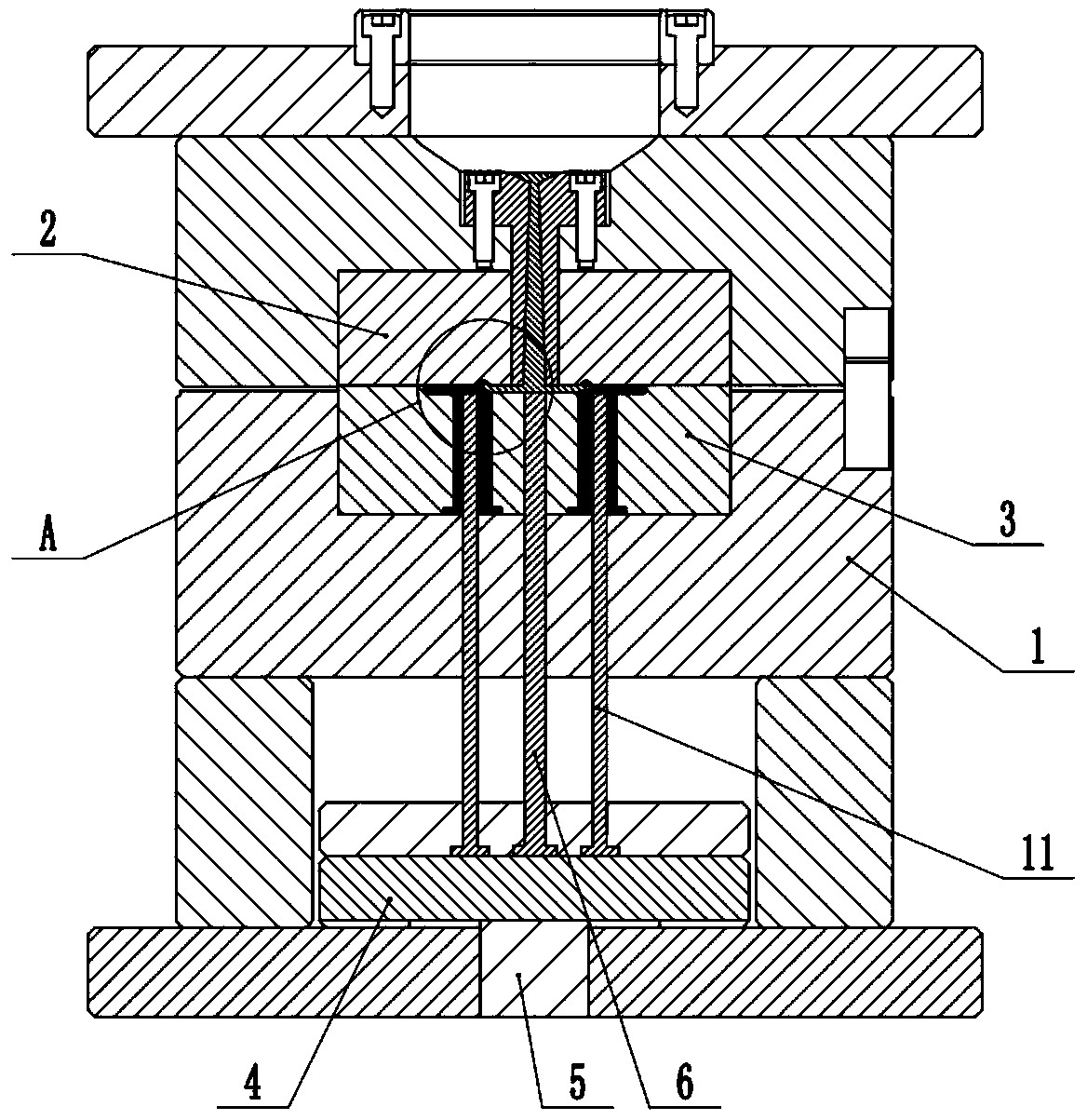

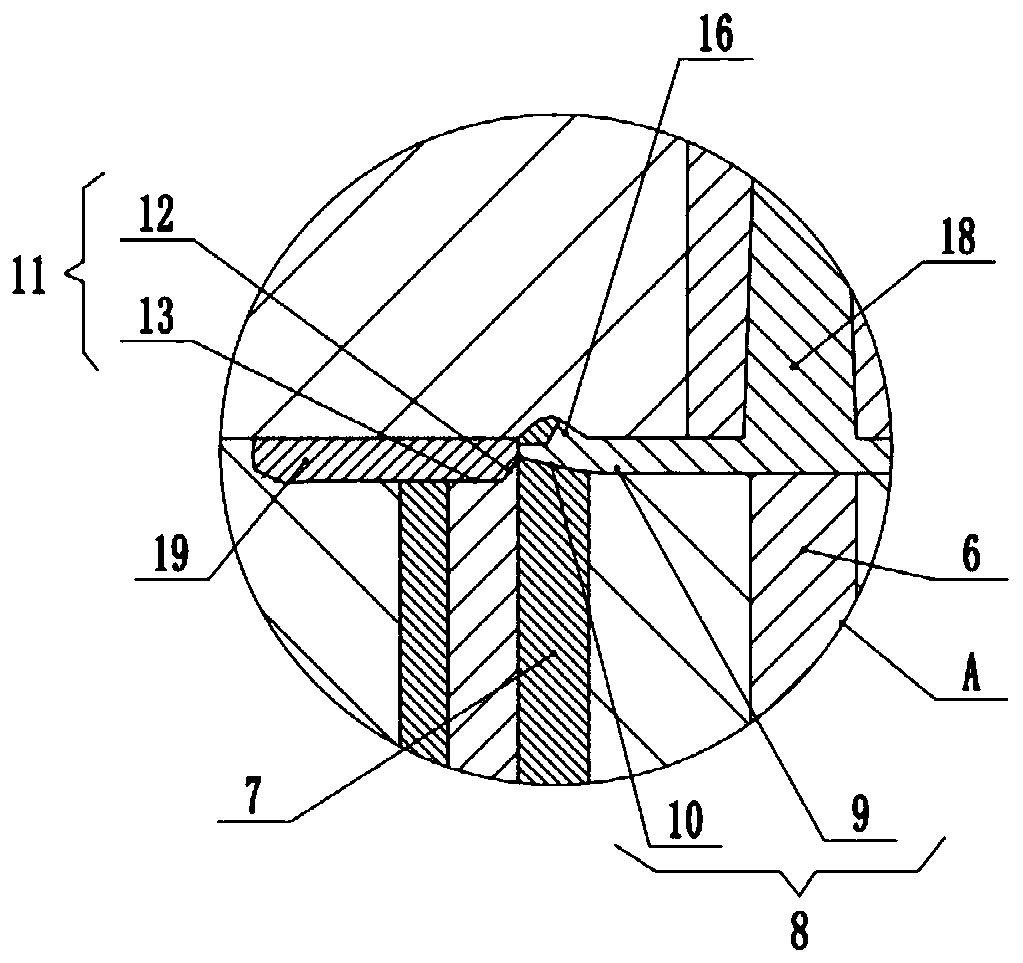

[0040] Example one is basically figure 2 , image 3 with Figure 4 As shown, an injection mold with automatic material cutting in the mold is provided with an ejection mechanism on the mold base 1. The ejection mechanism includes a push plate 4 vertically slidably connected to the mold base 1 and fixedly connected to the push plate 4 by screws. On the bottom driving ejector rod 5, the top of the push plate 4 is fixedly connected with a first ejector push rod 6 for demolding by screws.

[0041] Combine figure 2 with image 3 , The movable mold 3 is provided with a vertical matching hole, and a tunnel-type pouring sub 7 is coaxially arranged in the matching hole. The bottom end of the tunnel-type pouring sub 7 is fixedly connected to the movable mold 3 by screws. The upper end of the type pouring sub 7 passes through the parting surface of the movable mold 3 and the fixed mold 2 and then extends into the fixed mold 2. Therefore, correspondingly, the fixed mold 2 is provided with a...

Embodiment 2

[0054] The difference between the second embodiment and the first embodiment is: Figure 5 As shown, if the volume of the product 19 is large, so that the mating part 13 cannot easily demold the product 19, the second ejection push rod 17 can be fixedly connected to the push plate 4 by screws at this time, and the second ejection push rod The top of 17 matches the shape of the bottom surface of the cavity. During demolding, the second ejector pin 17 can push the product 19 upwards out of the movable mold 3, so that the demolding is completed smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com