Thermal transfer ribbon installation structure for thermal transfer printer

A technology of thermal transfer printer and installation mechanism, which is applied in the direction of printing and inking devices, and can solve the problems of complex installation or removal of carbon ribbons and the need for empty paper reels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

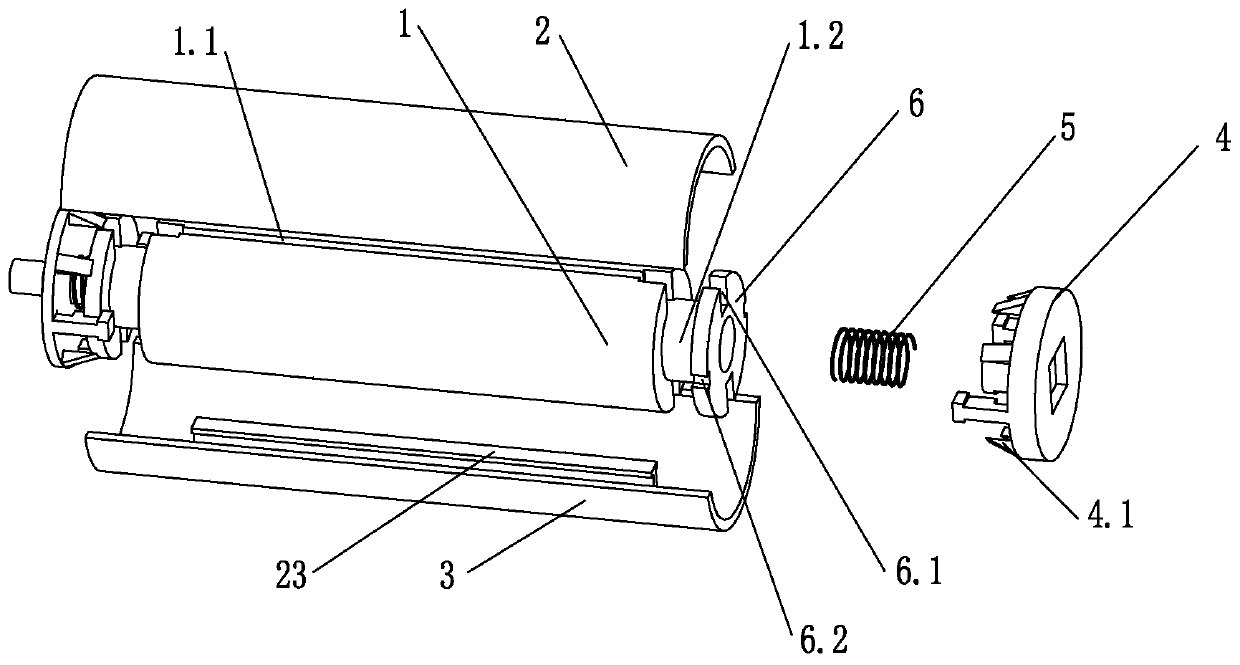

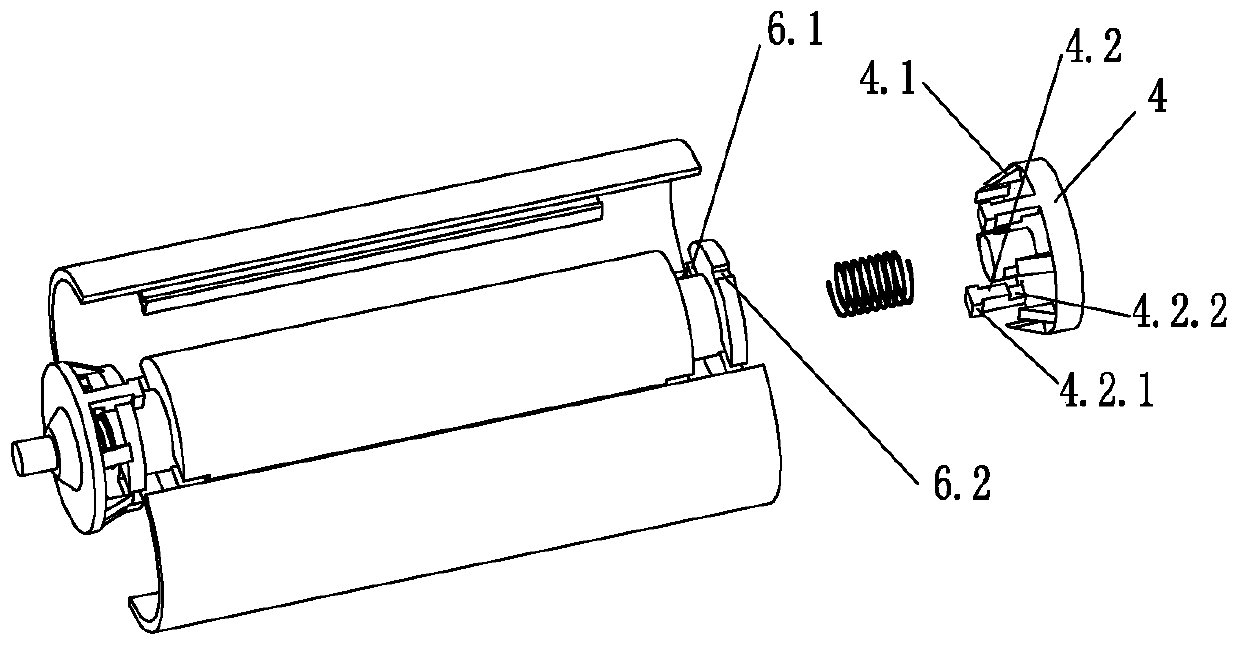

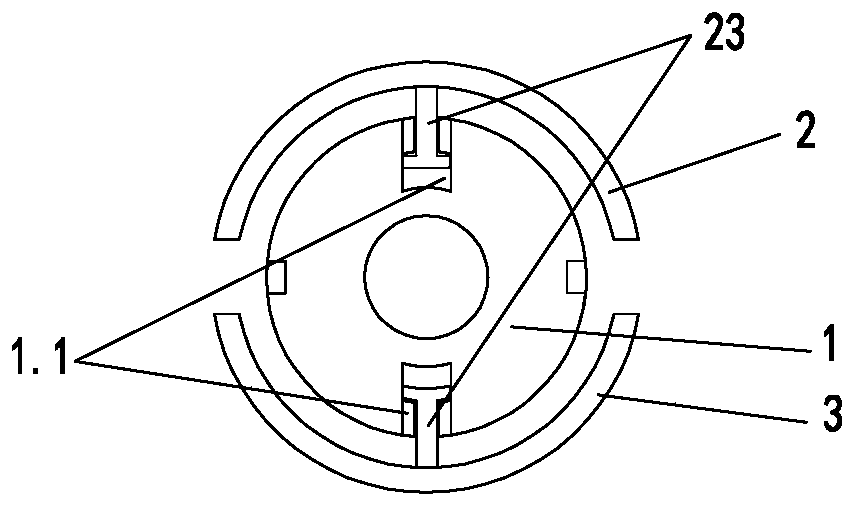

[0030] Such as Figure 1-6 As shown, the carbon ribbon installation mechanism of the thermal transfer printer of the present invention includes a main shaft 1 and a casing for installing the carbon ribbon and is located outside the main shaft 1, and is characterized in that the casing includes at least two pieces divided radially The formed shells have spacing between the side walls of adjacent shells, and each shell is limited in the circumferential direction with the main shaft 1 and slides in the radial direction. The two ends of the main shaft 1 are connected with brackets 4, and the brackets at one end The outer end of 4 is a rectangular hole, the outer end of the bracket 4 at the other end is a cylindrical protrusion, and the other structures are the same. The bracket 4 slides along the axial direction of the main shaft 1 and a spring 5 is arranged on the bracket 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com