A kind of diesel oil pour point depressant composition and its preparation method and application

A technology of diesel pour point depressant and composition, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of poor effect of diesel pour point depressant, and achieve the effect of enhancing the pour point depressant effect and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

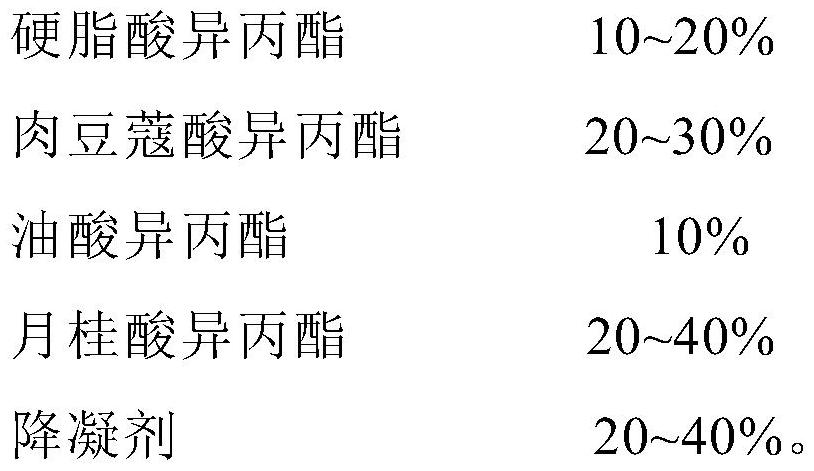

[0031] A diesel oil pour point depressant composition, calculated by mass percentage, each component and its content are as follows:

[0032]

[0033] Wherein, the pour point depressant used is EVA pour point depressant.

[0034] The above raw materials are directly mixed according to the mass ratio to obtain the diesel pour point depressant composition.

[0035] The composition is added to Songjiang 0# diesel oil according to the mass of 0.15%, and ultrasonically dispersed at 40°C for 30 minutes. After testing, the condensation point and cold filter point of the commercially available 0# diesel oil containing the diesel pour point depressant composition obtained in the above examples were lowered by 10°C and 5°C, respectively.

Embodiment 2

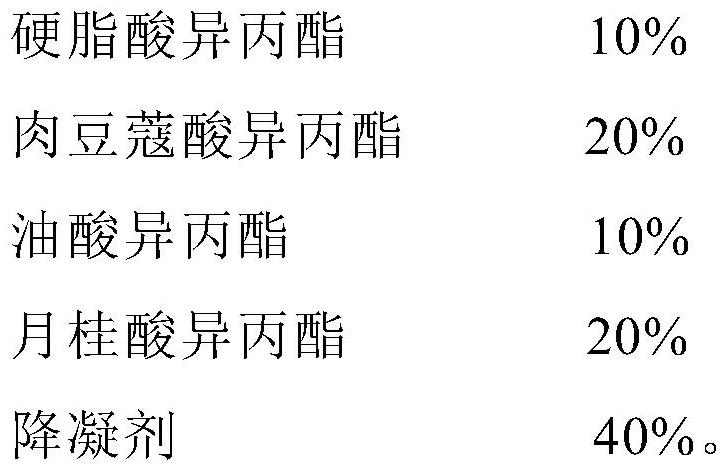

[0037] A diesel oil pour point depressant composition, calculated by mass percentage, each component and its content are as follows:

[0038]

[0039] Wherein, the pour point depressant used is EVA pour point depressant.

[0040] The above raw materials are directly mixed according to the mass ratio to obtain the diesel pour point depressant composition.

[0041] The composition is added to Songjiang 0# diesel oil according to the mass of 0.15%, and ultrasonically dispersed at 40°C for 30 minutes. After testing, the condensation point and cold filter point of the commercially available 0# diesel oil containing the diesel pour point depressant composition obtained in the above examples were lowered by 13°C and 11°C, respectively.

Embodiment 3

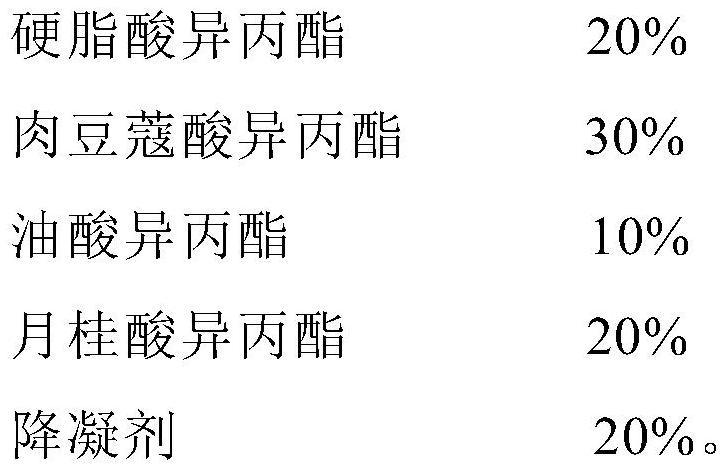

[0043] A diesel oil pour point depressant composition, calculated by mass percentage, each component and its content are as follows:

[0044]

[0045] Wherein, the pour point depressant used is EVA pour point depressant.

[0046] The above raw materials are directly mixed according to the mass ratio to obtain the diesel pour point depressant composition.

[0047] The composition is added to Songjiang 0# diesel oil according to the mass of 0.15%, and ultrasonically dispersed at 40°C for 30 minutes. The condensation point and cold filter point of the commercially available 0# diesel oil containing the diesel pour point depressant composition obtained in the above examples were lowered by 12°C and 3°C, respectively.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap