A Method for Quickly Determining Specific Leakage Points of Blast Furnace Staves Online

A technology of cooling wall and leakage point, applied in the direction of cooling device, etc., can solve the problems of cooling wall damage, heavy workload, complicated operation, etc., and achieve the effect of shortening the processing cycle, reducing the workload and reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

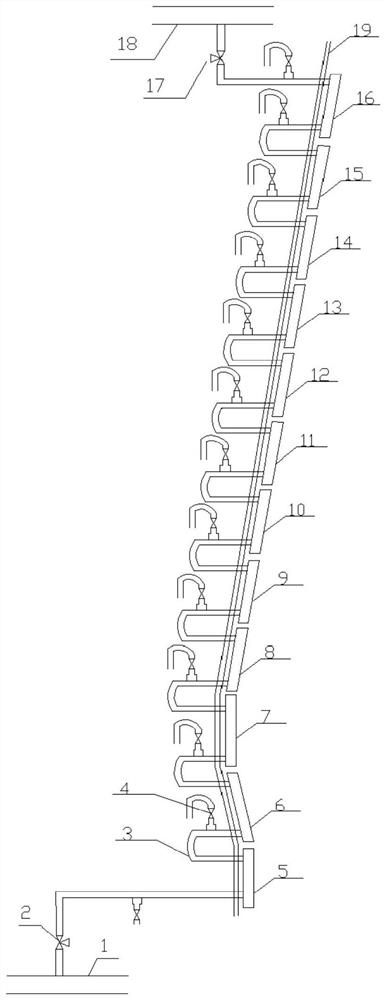

[0040] see figure 1 , a method for quickly determining the specific leakage point of the blast furnace stave on-line in the present embodiment, it comprises the following steps:

[0041] Step 1, using the known pressure holding method to determine the column where the damaged cooling wall is located;

[0042] Step 2: Connect each adjacent two staves of the row through connecting pipes 3, each connecting pipe 3 is provided with an exhaust valve 4, and the outlet end of the exhaust valve 4 is connected with an opening facing downwards. U-shaped tube, which is beneficial to observe the water outlet condition;

[0043] The exhaust valve 4 is connected from the short wire welded on the connecting pipe to the valve, and adopts a diameter change from large to small, so that the outlet water is not easy to diverge;

[0044] Step 3. Change the row w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com