Operation control method, operation control device, air conditioner and storage medium

A technology for operation control and air conditioners, applied in the field of computer-readable storage media, can solve problems affecting user experience and energy waste, reduce the risk of frosting, meet heating needs, and improve user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

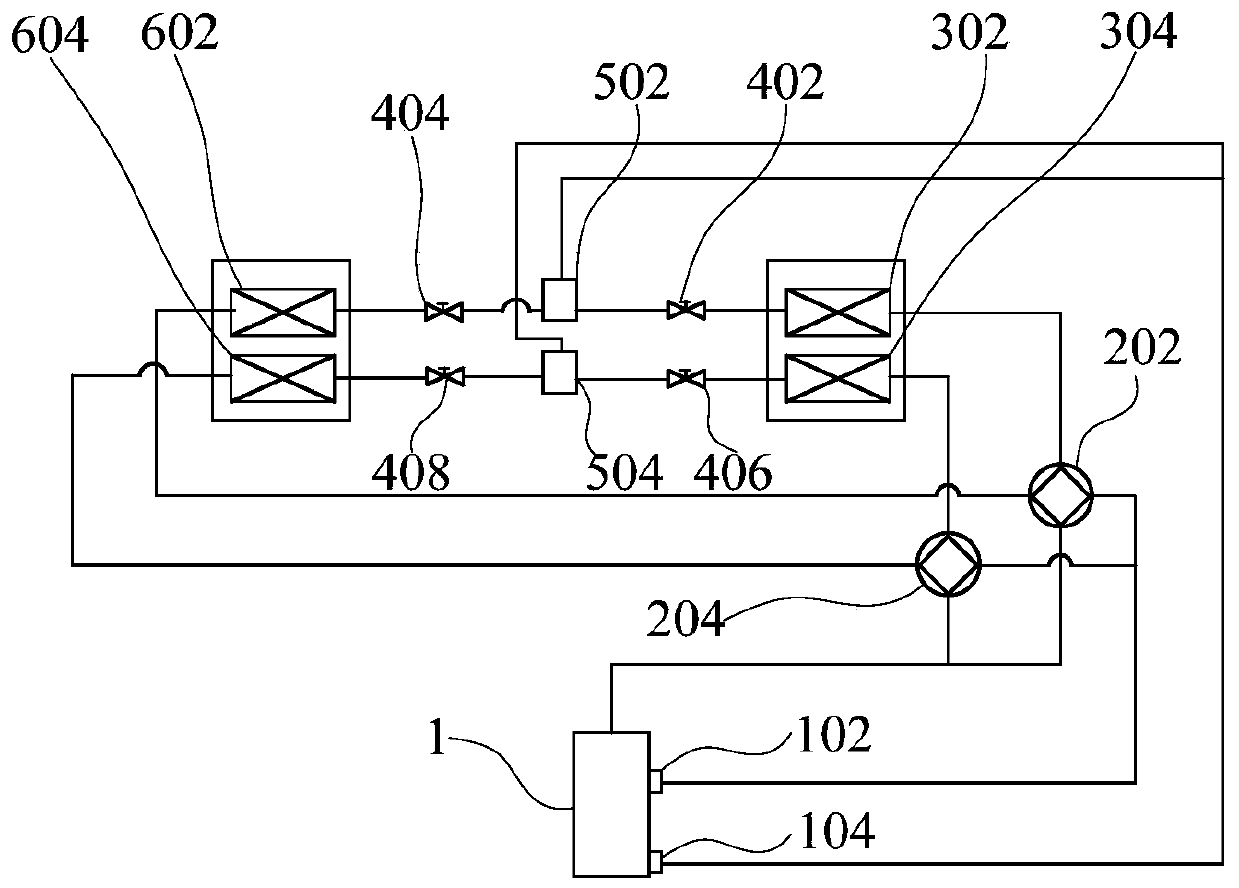

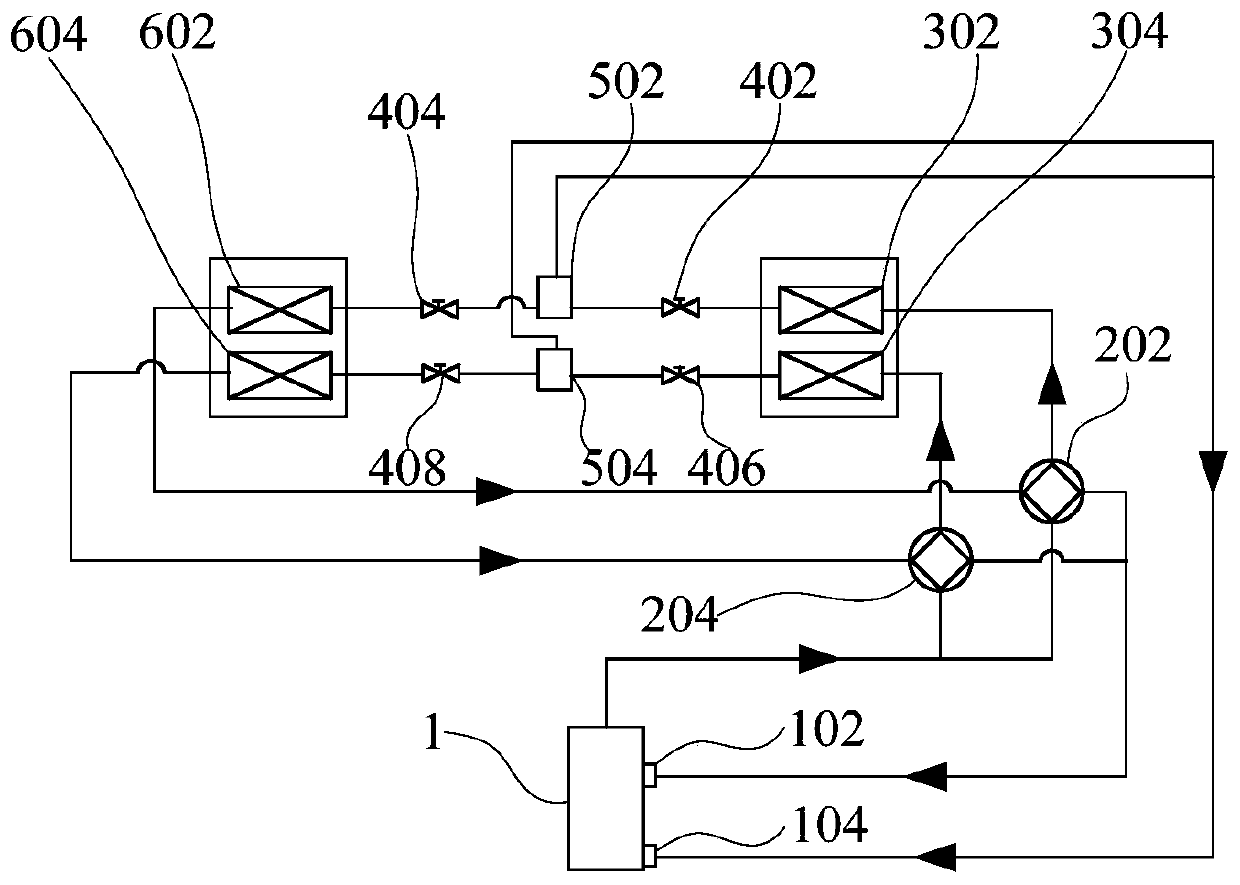

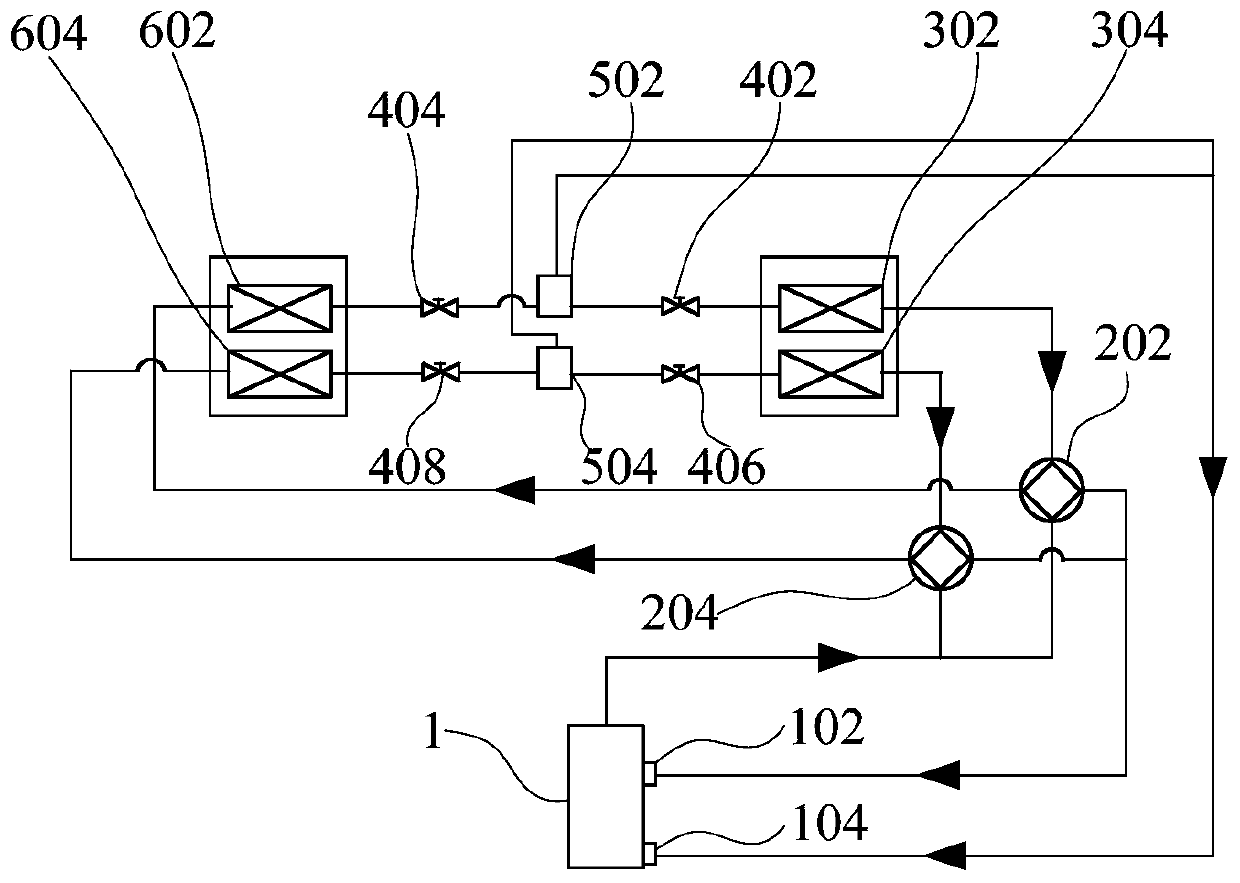

[0074] like figure 1 As shown, in any of the above embodiments, optionally, the multi-stage outdoor heat exchange unit includes a first outdoor heat exchange unit 302 and the second outdoor heat exchange unit 304, and the multi-stage indoor heat exchange unit includes a first indoor heat exchange unit 602 and the second indoor heat exchange unit 604, the multiple reversing assemblies include the first reversing assembly and 202 the second reversing assembly 204, the multiple air return ports include the first air return port 102 and the second air return port 104, the first return air port The air port 102 is connected to the second port of the first reversing assembly 202, the third port of the first reversing assembly 202 is connected to the first outdoor heat exchange unit 302, and the fourth port of the first reversing assembly 202 is connected to the first indoor Heat exchange unit 602; the first air return port 102 is connected to the second port of the second reversing ...

Embodiment 2

[0078] In addition, a first throttling device 402 (close to the outdoor heat exchanger) and a second throttling device 404 (close to the indoor heat exchanger) are respectively arranged on both sides of the first gas-liquid separator 502, and the second gas-liquid separator The third throttling device 406 (near the outdoor heat exchanger) and the fourth throttling device 408 (near the indoor heat exchanger) are respectively arranged on both sides of the 504, and the opening and closing of different throttling devices are controlled by the controller, combined with the exchange Control the flow direction of the refrigerant in the components, and open different refrigerant defrosting circulation paths for defrosting the outdoor heat exchanger in different working conditions to meet the defrosting requirements of different working conditions.

[0079] In any one of the above embodiments, optionally, the reversing assembly is a four-way valve; the throttling device includes one or ...

Embodiment 3

[0084] like Figure 4 As shown, in the above embodiment, optionally, in the defrosting mode, determine the preset temperature range to which the outdoor ambient temperature belongs, so as to determine the defrosting control parameters corresponding to the preset temperature range, specifically including: In mode, if it is detected that the outdoor ambient temperature belongs to the first temperature range, the control opens the throttling component on the first refrigerant flow path, adjusts the first reversing component to the first flow direction, and controls the operation of the first compression chamber so that the high temperature The gaseous refrigerant flows into the first outdoor heat exchange unit on the windward side through the first reversing assembly, and flows into the corresponding first indoor heat exchange unit through the first refrigerant flow path after performing a heat exchange operation.

[0085] In this embodiment, in the first defrosting control strat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com