Plastic body automatic sorting machine for pin header connector

A technology of plastic body and connector, which is applied in the direction of connection, assembly/disassembly of contacts, circuit/collector parts, etc., can solve the problems of high production cost and low production efficiency, and achieve high quality risk and low resolution efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

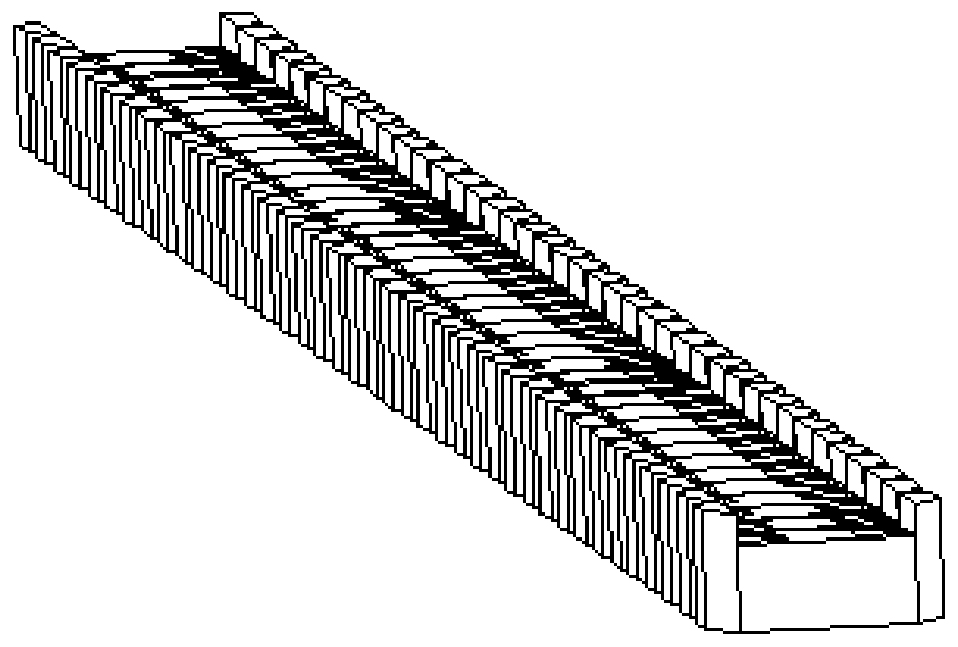

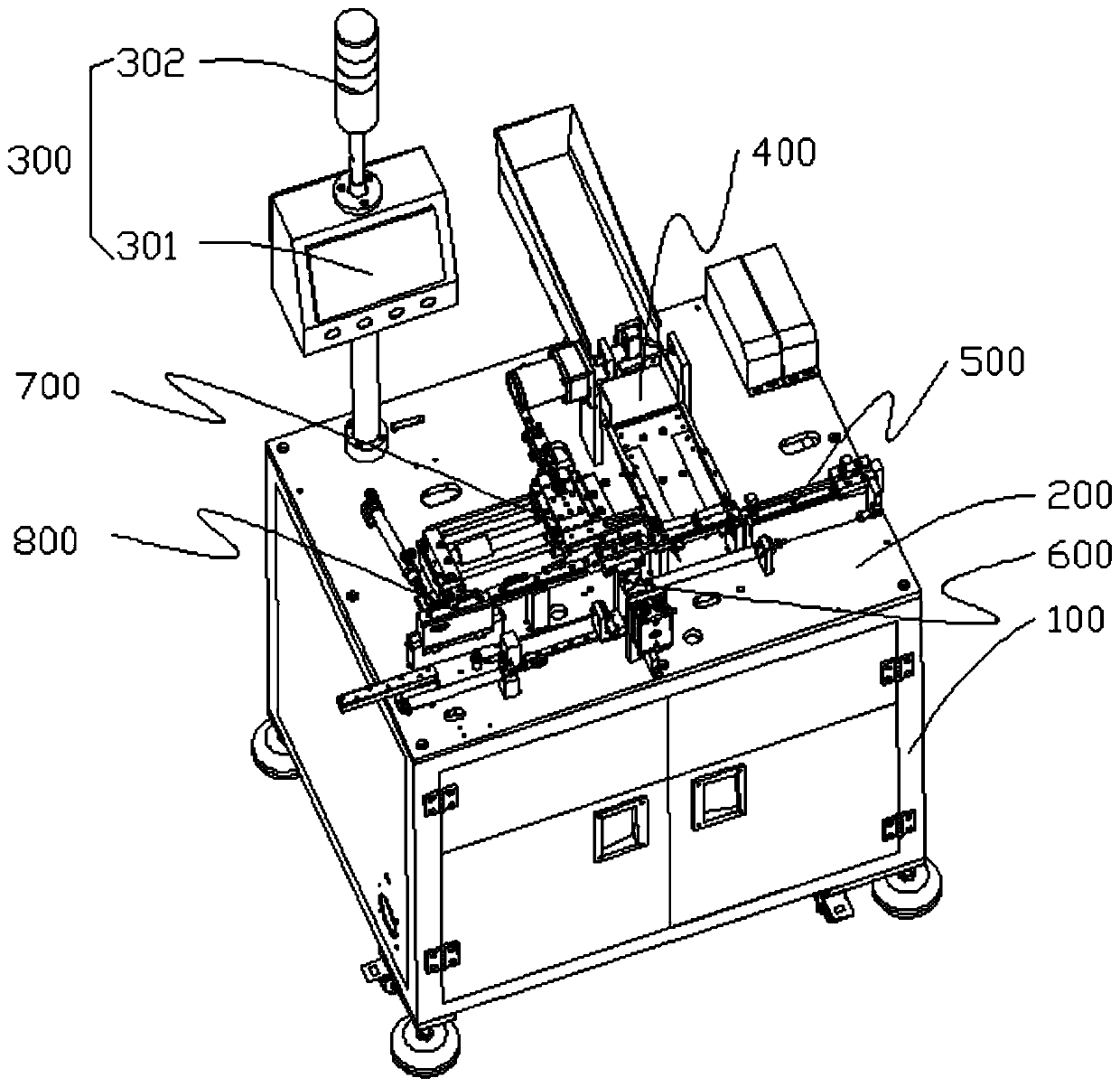

[0032] Embodiment 1: When using the plastic body automatic material selection machine of the pin header connector for the column-free structure plastic body, as image 3 Shown: a plastic body automatic material selection machine for pin connectors; including a frame 100, a workbench 200 on the frame and a control box 300 on the workbench, the control box 300 is A touch screen 301, a control core board (not shown) electrically connected to the touch screen and an alarm 302 electrically connected to the control core board are provided; the workbench 200 is provided with a vibration feeder along the flow direction of the plastic body in sequence. Material unit 400, material pushing unit 500, rotation reversing unit 600, fork material transplanting unit 700 and rotary discharging unit 800; 1. The fork material transplanting unit 700 and the rotary discharging unit 800 are respectively electrically connected to the control core board (not shown); under the control of the control bo...

Embodiment 2

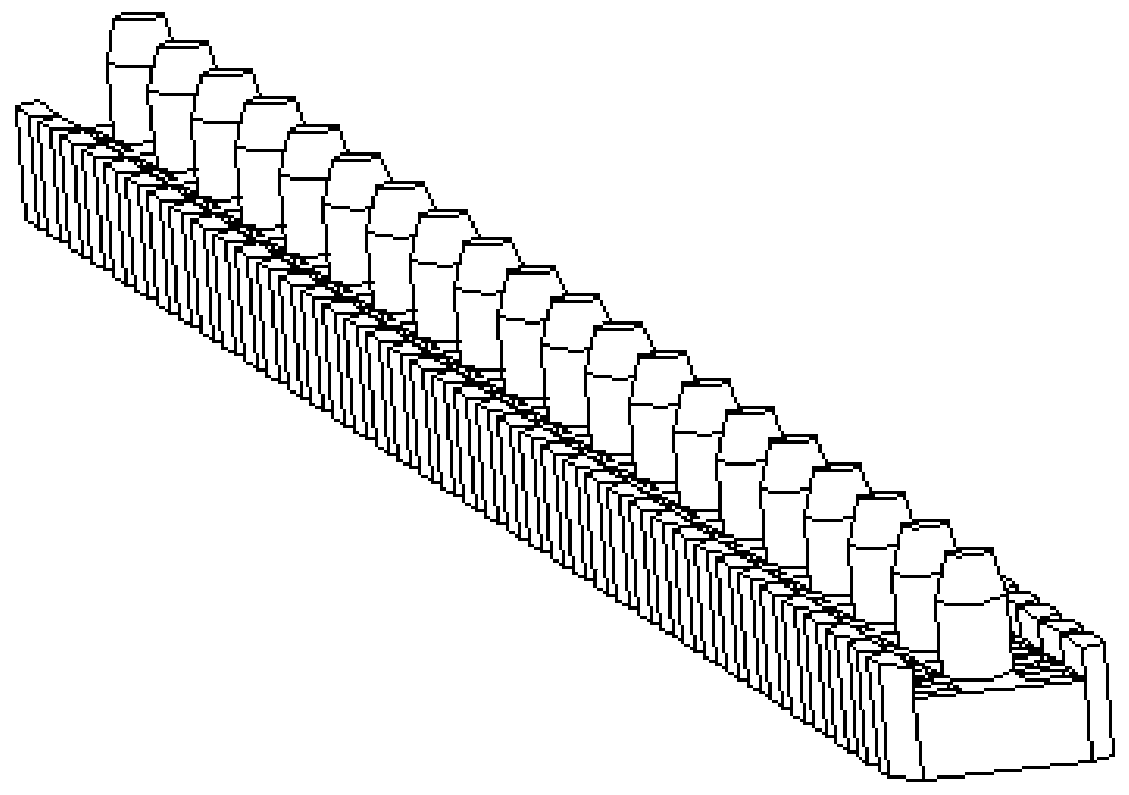

[0041] Embodiment 2: When using the plastic body automatic material selection machine of the pin row connector for the plastic body with a column structure, such as Figure 10 with Figure 11 As shown: the plastic body with column structure and the plastic body without column structure are different from the plastic body automatic material selection machine using this needle connector in that the rotation reversing unit 600 and the fork material transplanting unit 700 There are some differences in the combination positions of the other components. The structures of the other vibrating feeding unit 400, the pushing unit 500 and the rotating discharging unit 800 are the same, and will not be repeated here.

[0042] see Figure 11 As shown: the rotation reversing unit 600 includes a first rotary cylinder 601 provided on the workbench 200, a rotary track 602 set on the output shaft of the first rotary cylinder, and two groups of A first pressing assembly 610; a second through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com