Pencil sharpening equipment for stationery processing

A grinding and pencil technology, which is applied to metal processing equipment, grinding/polishing equipment, non-active pencils, etc., can solve the problems of easy wear of debris, time-consuming, high processing costs, etc., to reduce equipment wear rate, reduce Cost and Time Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

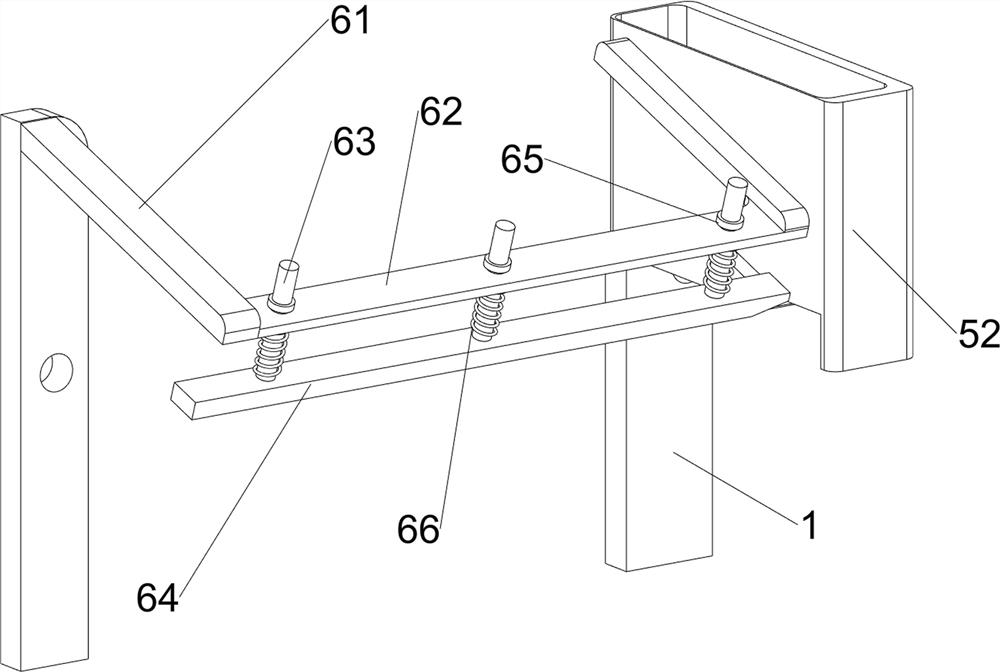

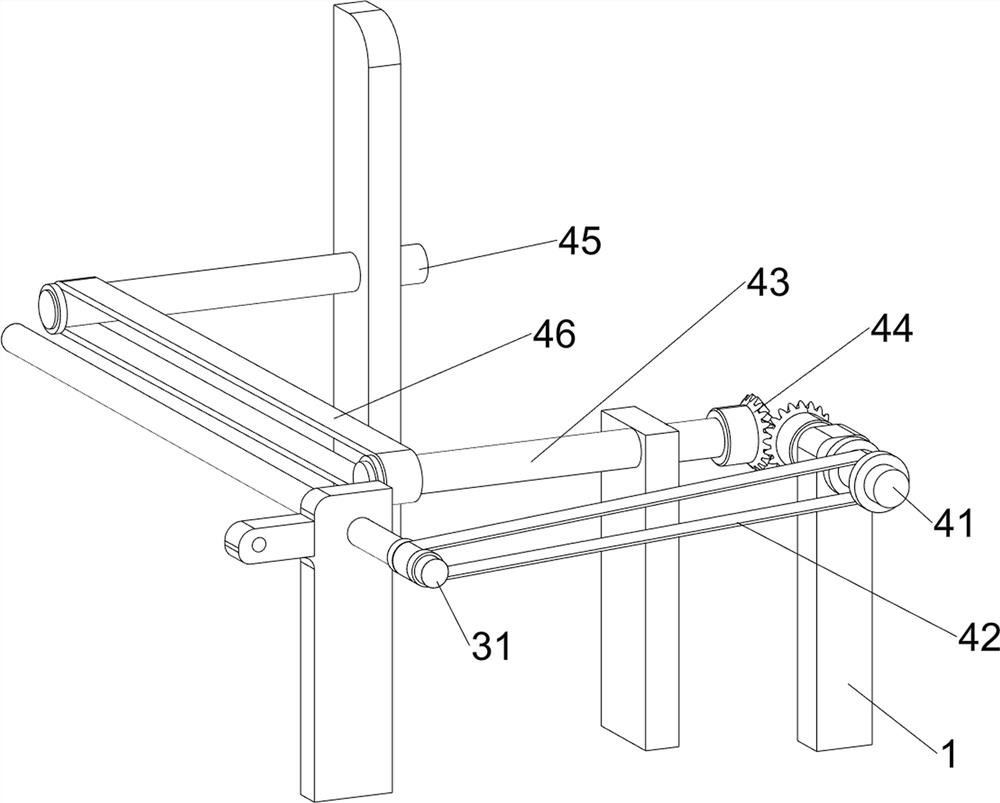

[0025] A pencil sharpening device for stationery processing, such as Figure 1-Figure 6 As shown, it includes a bottom plate 1, a servo motor 2, a grinding mechanism 3, a feeding mechanism 4 and a storage and guide mechanism 5. The bottom plate 1 is provided with a servo motor 2 at the rear on the right side, and a grinding mechanism 3 is provided at the front end of the upper part of the bottom plate 1. The upper right side of the bottom plate 1 is provided with a material-carrying mechanism 4, which is connected with the servo motor 2 and the grinding mechanism 3, and the upper part of the material-carrying mechanism 4 is provided with a storage and guide mechanism 5.

[0026] When people need to grind pencil raw materials, they first put the pencils into the storage guide mechanism 5 in turn, then start the servo motor 2, the servo motor 2 drives the grinding mechanism 3, and the grinding mechanism 3 drives the belt material mechanism 4 to move, driving the pencil Moving to...

Embodiment 2

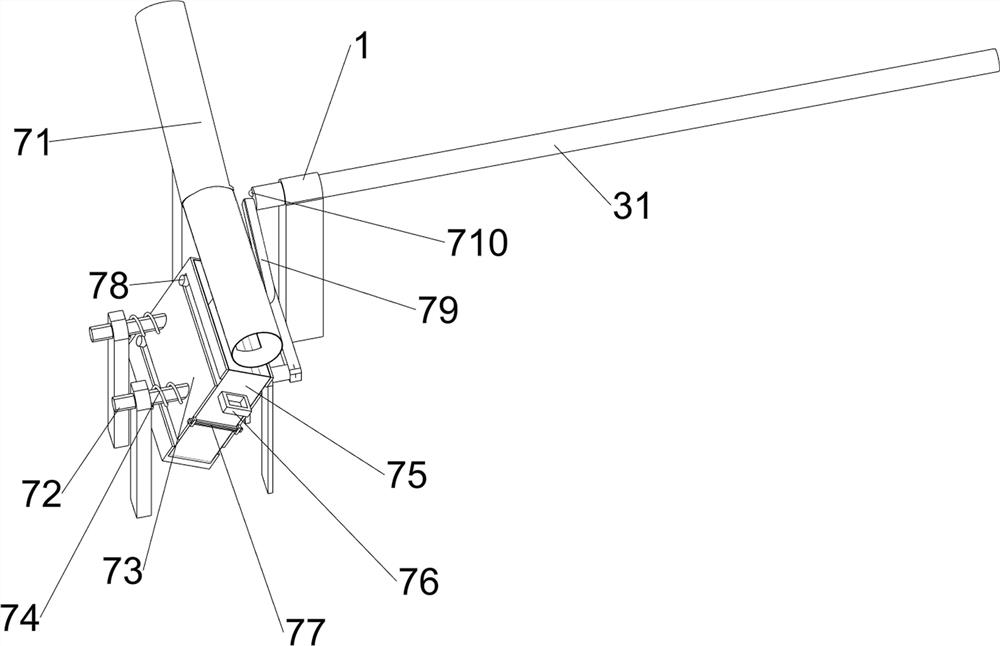

[0036] On the basis of Example 1, such as figure 1 , figure 2 , Figure 7 and Figure 8 Shown, also include unloading mechanism 7, bottom plate 1 left side is provided with unloading mechanism 7, unloading mechanism 7 includes material guide tube 71, slide bar 72, material holding outer box 73, second spring 74, containing Material inner box 75, handle 76, bayonet pin 77, first bump 78, shifting block 79 and second bump 710, bottom plate 1 top is provided with feed pipe 71, feed pipe 71 is connected in the middle of first rotating shaft 31 top left Side, bottom plate 1 upper left side is provided with symmetrical slide bar 72 on left and right sides, is provided with material-filling outer box 73 in the middle of both side slide bar 72, is provided with second spring 74 between both side slide bar 72, and material-filling outer box 73 interiors are provided with material-filled inner box 75, and filled-material inner box 75 front sides are provided with handle 76, and fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com