A high-efficiency heat dissipation power distribution cabinet

A power distribution cabinet, high-efficiency technology, applied in substation/distribution device housing, electrical components, substation/switch layout details, etc., can solve the problems of low space utilization, high temperature of internal accessories, poor heat dissipation function, etc. Improve heat dissipation efficiency and operational stability, increase the number of installations, and control the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

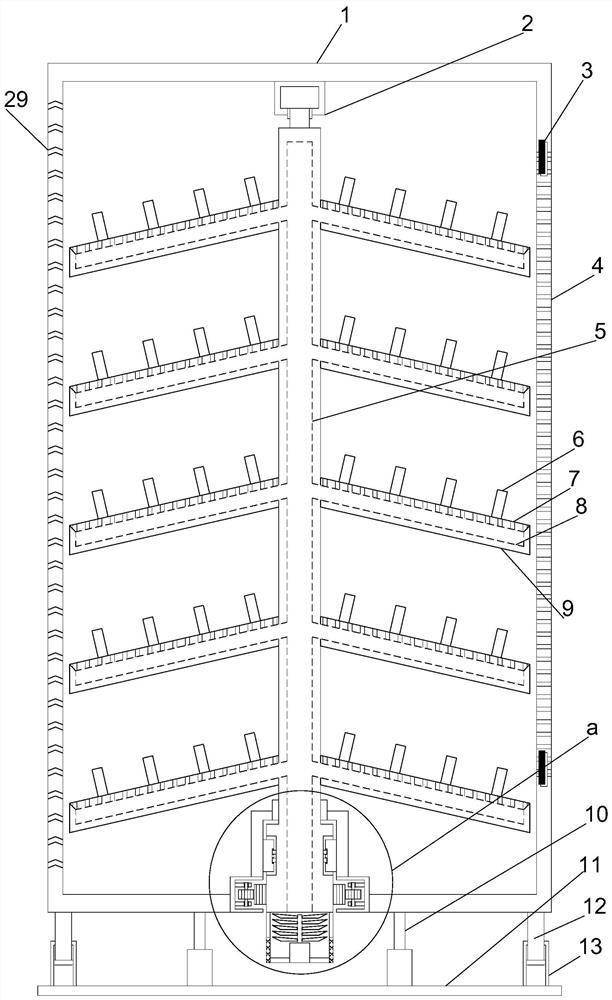

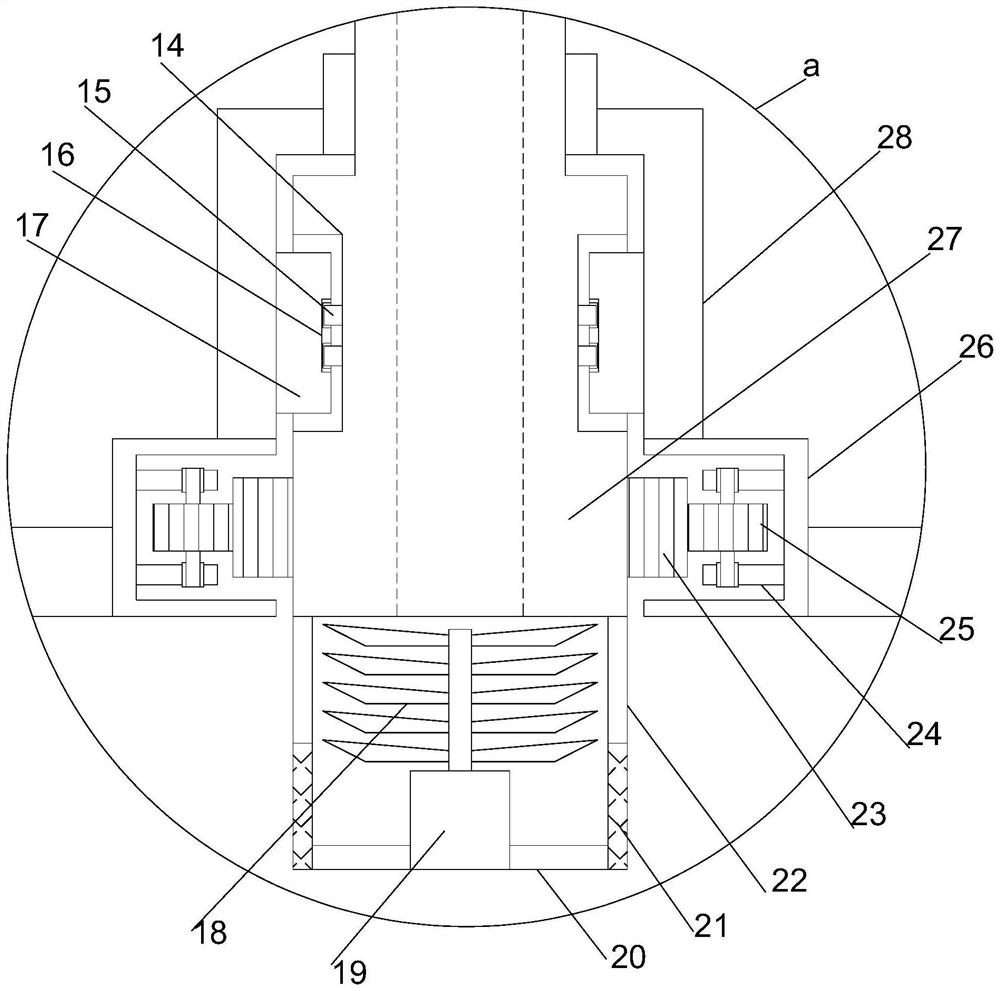

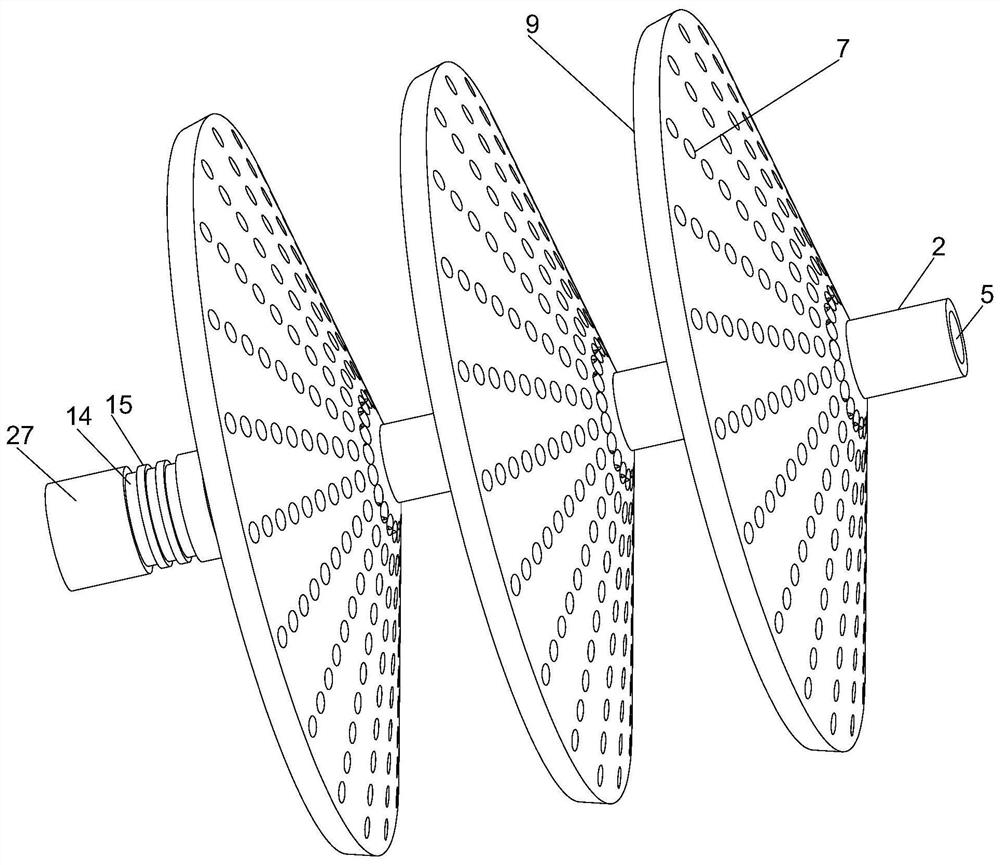

[0023] see Figure 1~3 , in the embodiment of the present invention, a high-efficiency heat dissipation power distribution cabinet includes a vertically arranged support installation cylinder 1, a support installation plate 11 is horizontally arranged directly below the support installation cylinder 1, and the right end of the support installation cylinder 1 is connected by a hinge 3 Rotation is provided with a rotating door 4, a number of heat dissipation holes 29 are evenly arranged on the wall of the supporting installation cylinder 1, and a limited rotation column 27 is vertically arranged in the inner middle position of the supporting installation cylinder 1, and the top of the supporting installation cylinder 1 cooperates with the limited rotation The column 27 is provided with a limit installation sleeve 2, and the heat dissipation holes 29 are bent. The bottom of the support installation cylinder 1 cooperates with the limit rotation column 27 to set a limit rotation ins...

Embodiment 2

[0026] On the basis of the first embodiment, the height of the supporting installation cylinder 1 can be changed stably by using the position-limiting support guide column 12 and the position-limiting support guide cylinder 13 in conjunction with the electric lifting column 10 to ensure the stable operation of the internal electronic components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com