Material side line positioning method for automobile testing silencer end cover composite molding mold

A technology of automobile testing and compound molding, which is applied in the field of automobile parts processing, can solve the problems of high cost, unsuccessful commissioning, long cycle, etc., and achieve the effect of saving processing costs, saving development costs, and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

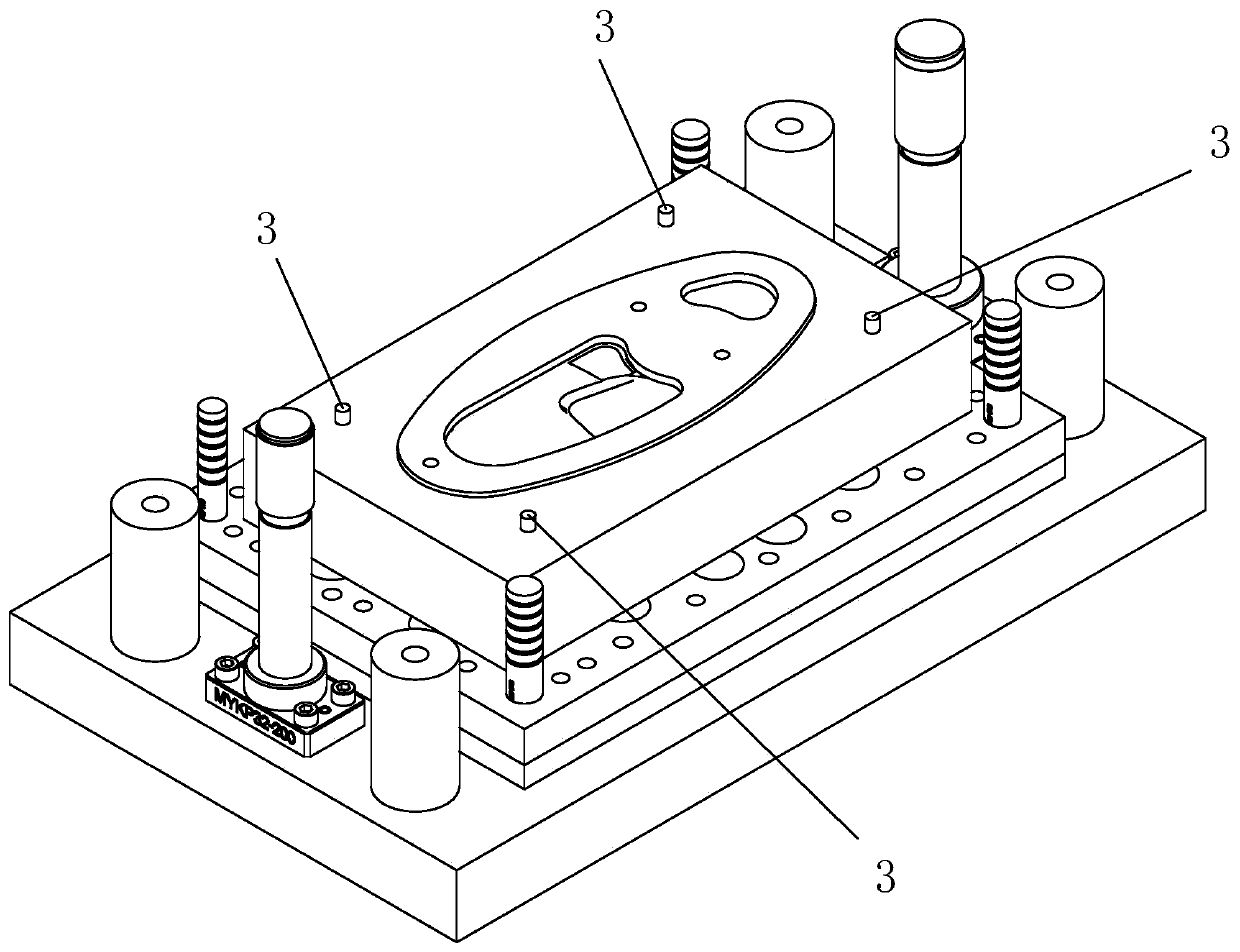

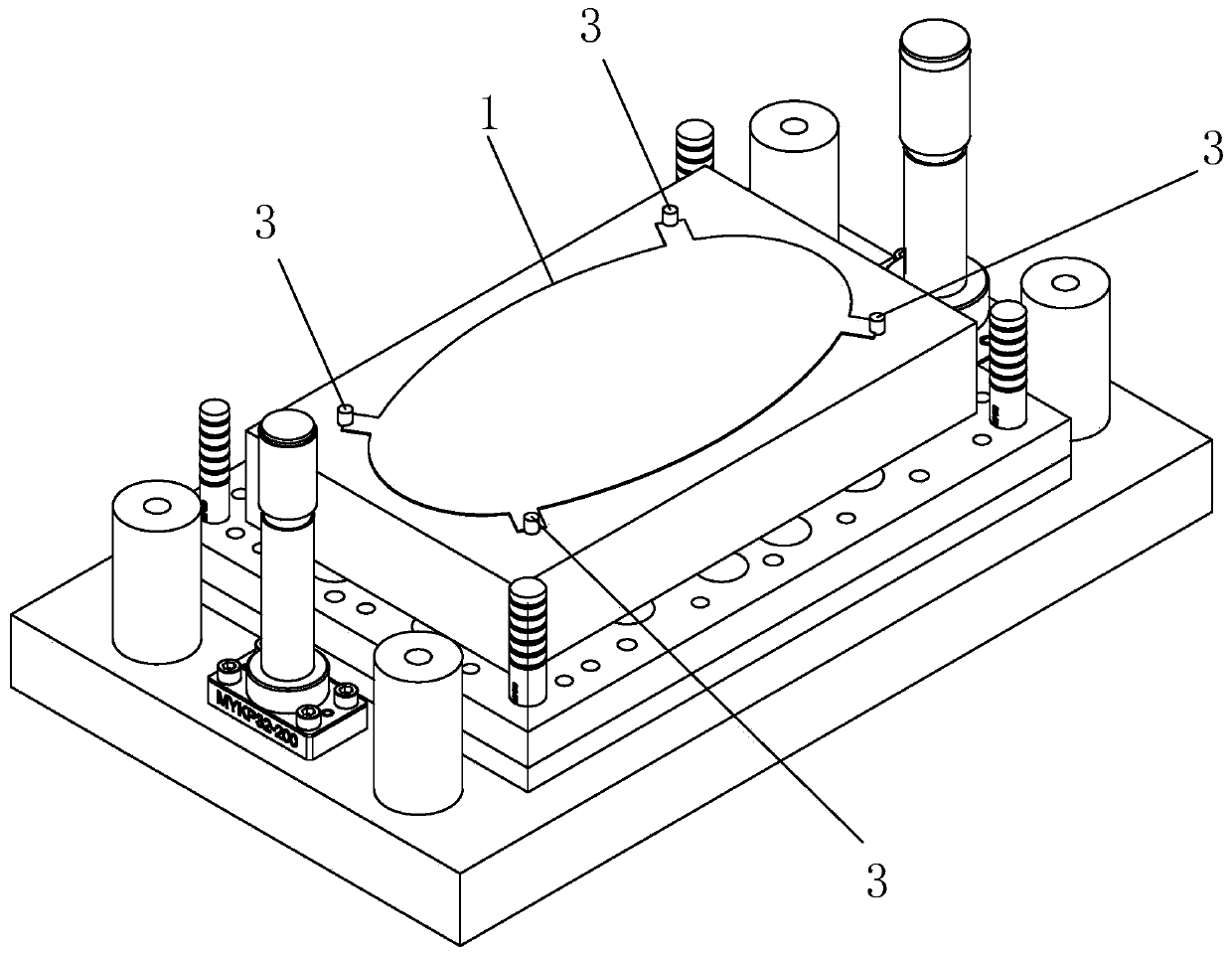

[0015] Such as Figure 1 to Figure 3 As shown, this embodiment provides a method for locating the edge line of the composite molding die for the automobile test muffler end cover. It should be noted that the "first", "second", "third" etc. in this embodiment The term of serial number is only used to distinguish similar components, and cannot be understood as a specific limitation on the scope of protection. In addition, directional terms such as "bottom", "top", and "side edge" in the present embodiment are described based on the drawings.

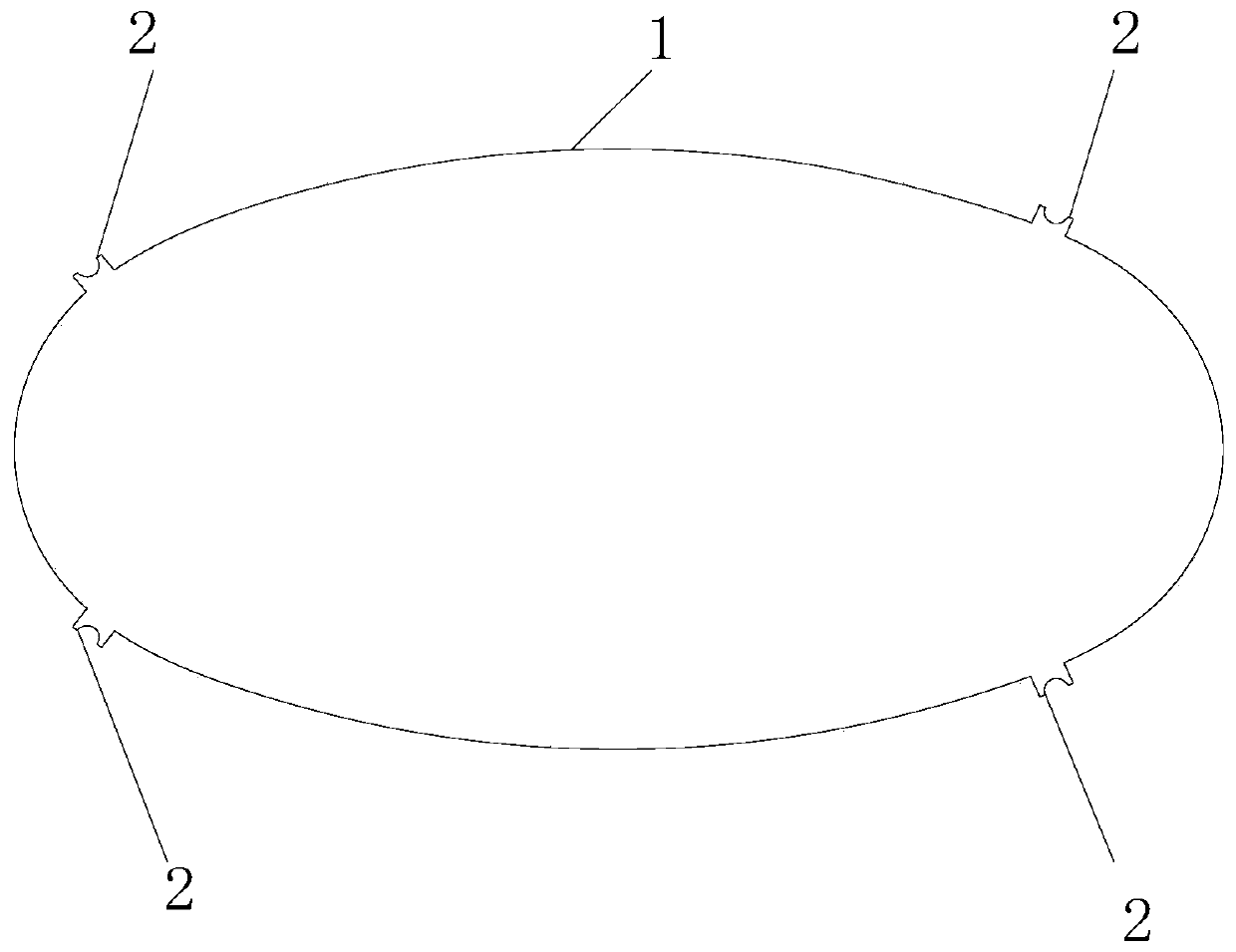

[0016] The automobile test muffler end cover compound molding mold uses a material edge positioning method, and four positioning notches 2 are set on the outer edge of the blanking dimension line 1 of the blank, and the four positioning notches 2 are used in different positions to prevent fooling, that is, to avoid The four positioning notches 2 are formed symmetrically or uniformly, so as to prevent the blanks from being indistinguishabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com