Integral sliding method of floating dock wall

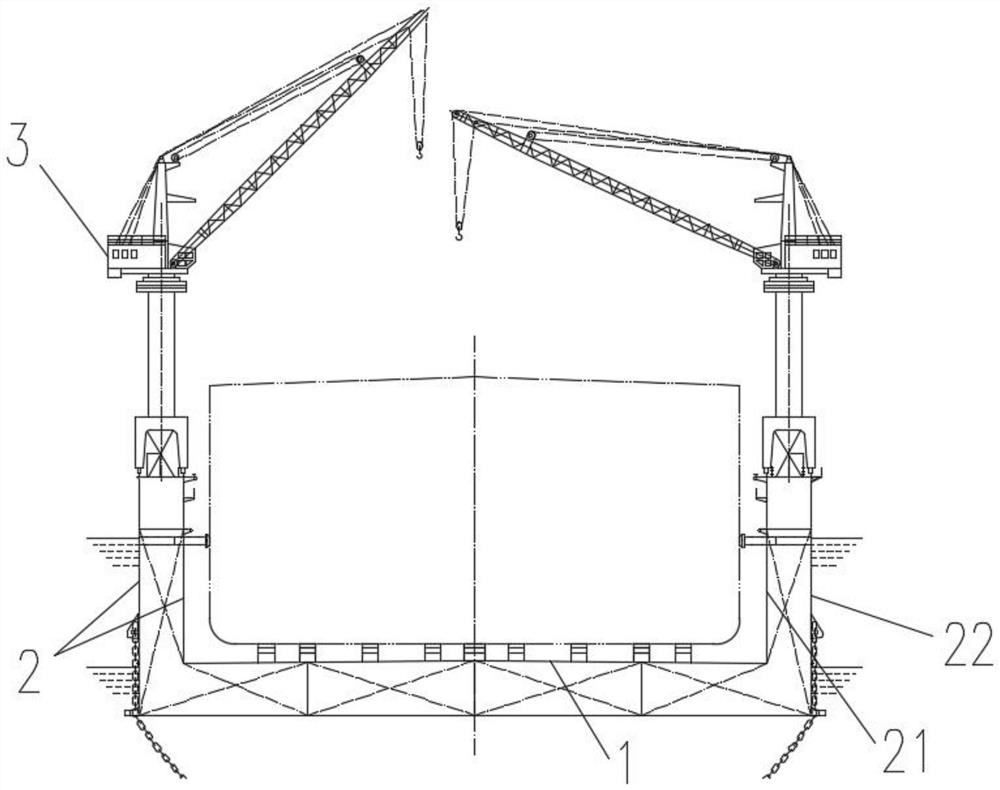

An integral sliding, docking wall technology, applied in dry dock, ships, transportation and packaging, etc., can solve the problems of short moving distance, high wall, and high safety hazards, so as to improve construction controllability and reduce construction. Steps, the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

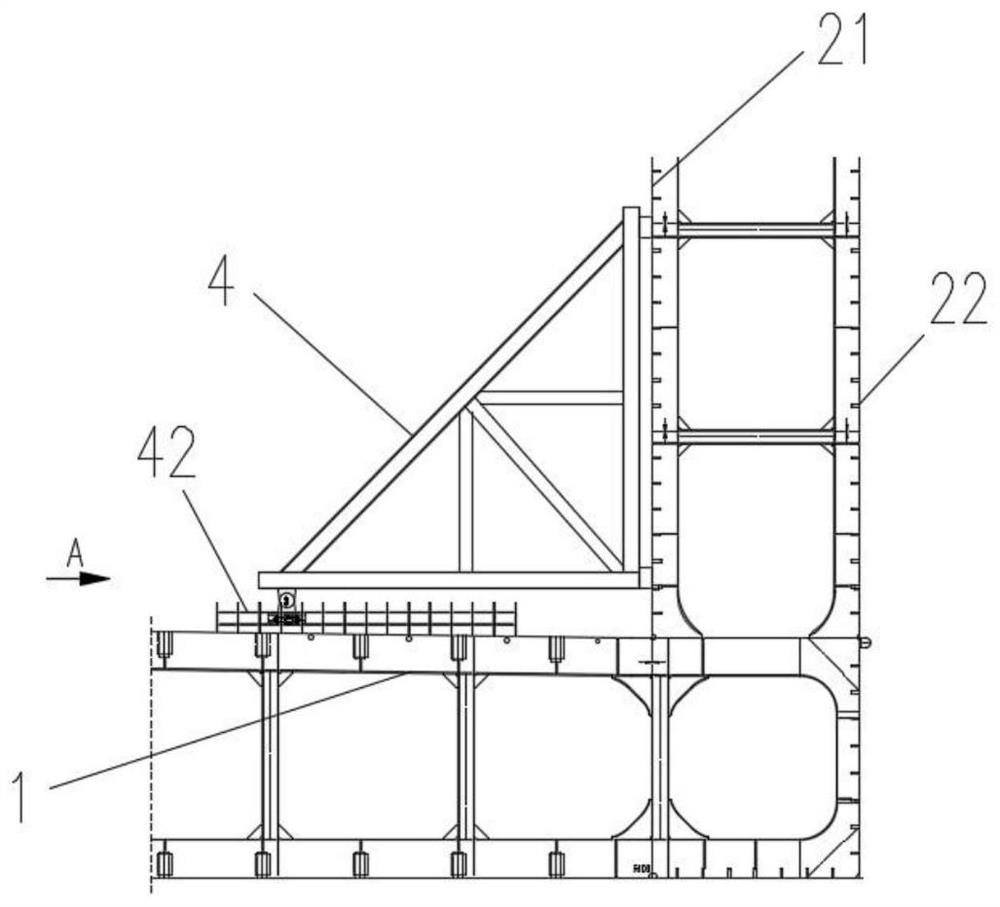

[0053] Jacking reinforcement bracket 6 comprises upper plate 61, lower plate 62, and the support plate 63 that is connected between upper plate 61 and lower plate 62; The reinforcement structure attached to wall 2, in Figure 10 attached to the inner wall of the inner dock wall 21 and the inner wall of the outer dock wall 22, not clearly shown in the figure), the two ends of the lower plate 62 are respectively welded and fixed to the inner dock wall 21 and the outer dock wall 22; 21 and the inner wall of the outer dock wall 22 are also provided with a bracket 64;

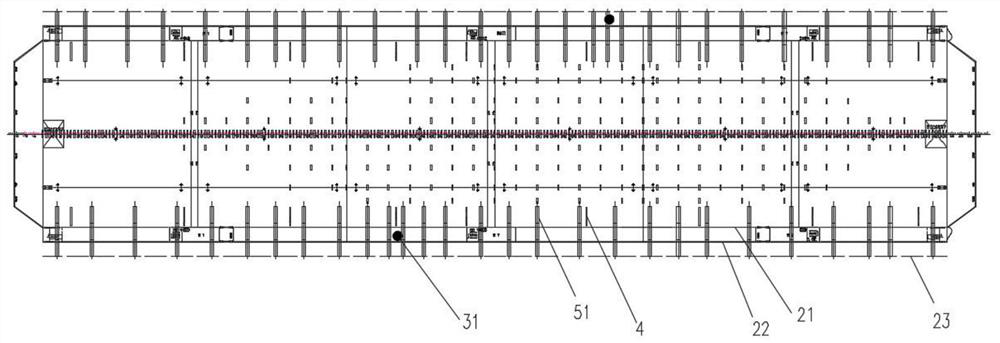

[0054] S7: if Figure 7 As shown, at the bottom of each dock wall opening 5, a cloud rail 51 (cloud type rail, used as a track for a heavy-duty vehicle 52) is fixedly installed, and the cloud rail 51 is fixed to the buoyancy tank 1 and runs through the dock wall opening 5; Cloud rail 51 stretches out from the two ends of dock wall opening 5, and wherein one end extends to the dock wall limit baffle plate 23 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com