Pipe microleakage detection method based on deep neural network

A deep neural network and leak detection technology, applied in the field of pipeline tightness detection and detection, can solve the problems of destroying the integrity of the pipeline, increasing the risk of pipeline leakage, and increasing the manufacturing cost of the pipeline, so as to alleviate the leakage risk, flexibly select, and enhance monitoring. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

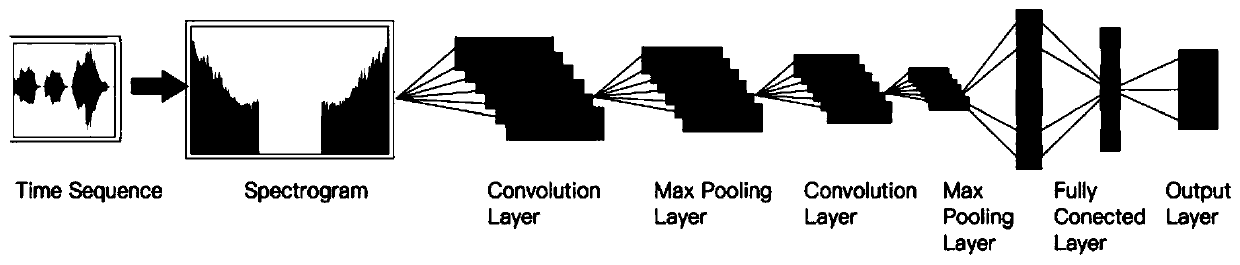

[0019] Such as Figure 5 As shown, the present invention provides a pipeline micro-leakage detection method based on a deep neural network that enhances the monitoring range of pipeline leakage, the detection point can be flexibly selected, and will not cause secondary damage to the original pipeline, including the following steps,

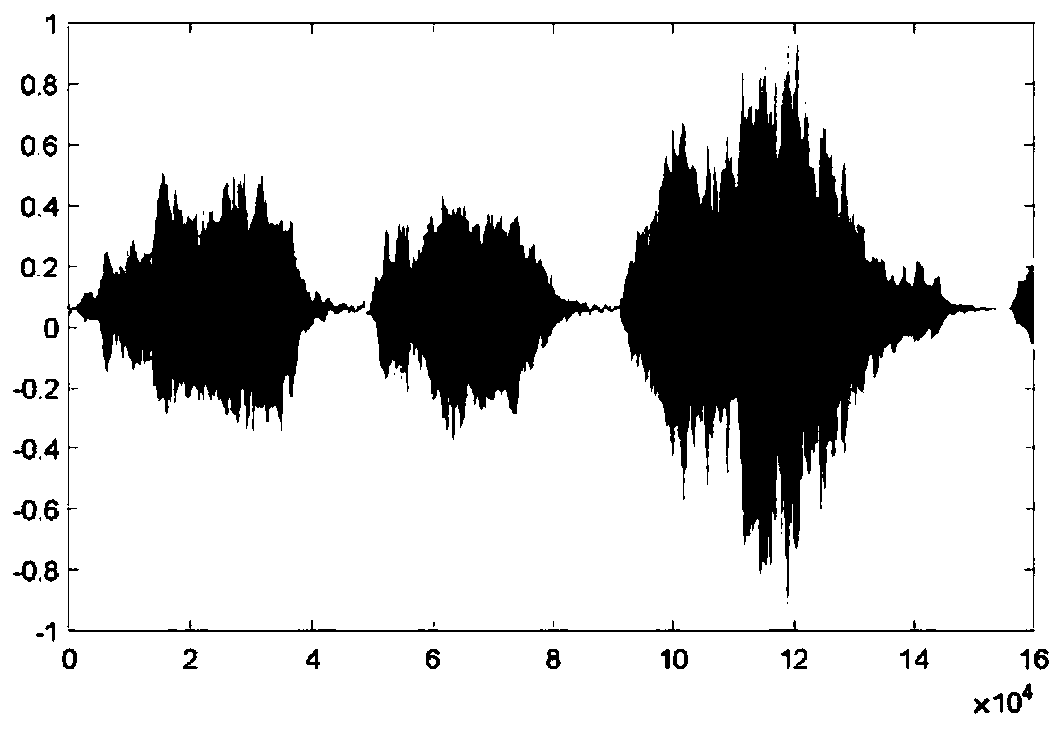

[0020] S1: the collected pipe leak audio;

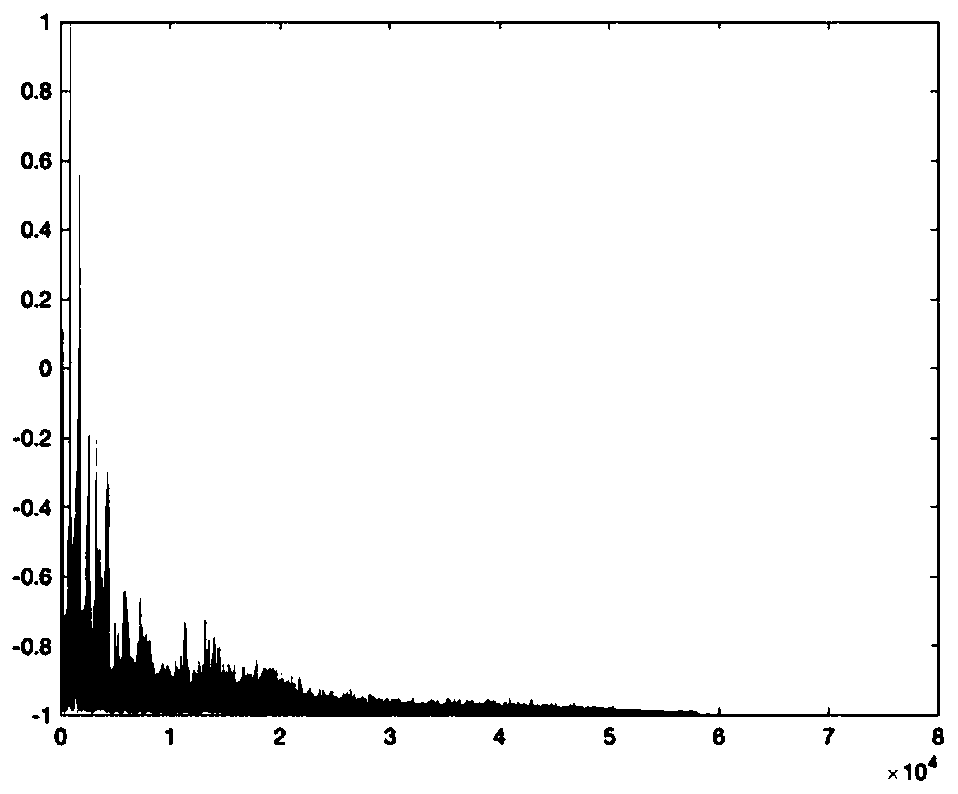

[0021] S2: Preprocess the data using the following formula,

[0022]

[0023] [Data] is the processed output audio spectrum matrix; abs is the absolute value function, n is a single audio metadata subscript, N is up to 160000, x(n) is the analog signal of audio sampling, j is the imaginary number unit, L is The data length is 160000, and k is one of the metadata subscripts of the n equal parts sampled data.

[0024] S3: Use the following formula to generate a pipeline micro-leakage detection model based on convolutional neural network,

[0025]

[0026] In the formula, P is the recognition error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com