a stamping method

A stamping forming and stamping device technology, applied in the stamping field, can solve the problems of non-steel plate protection, inconsistent corrugation amplitude of corrugated plates, positioning deviation, etc., to avoid positioning deviation, ensure the use effect, and avoid the effect of rebound deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

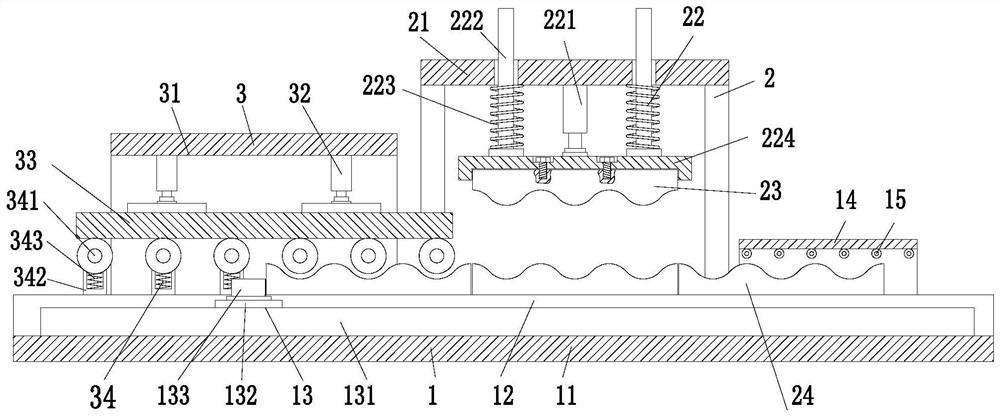

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

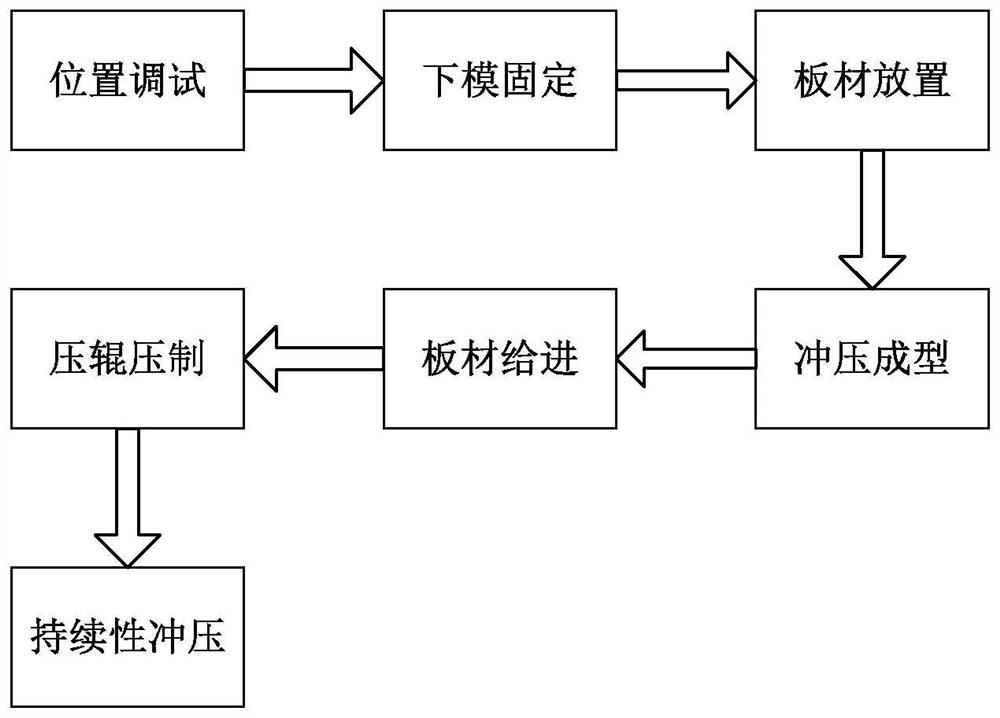

[0037] Such as Figure 1 to Figure 5 As shown, a stamping method includes the following steps:

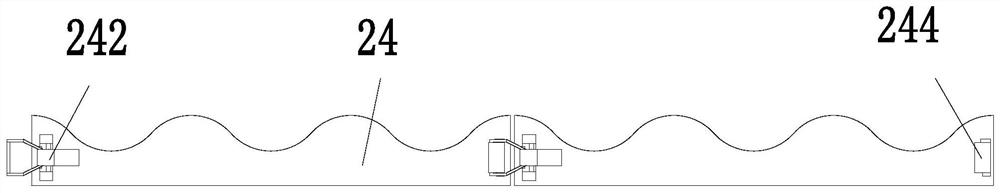

[0038] S1, position debugging: adjust the initial position of the lower template 24 according to the position of the upper template 23, so that the upper template 23 corresponds to the lower template 24;

[0039] S2, fixing the lower mold: after the lower template 24 in step S1 is debugged, connect the left end of the lower template 24 with the conveying mechanism;

[0040] S3, plate placement: clean foreign matter, impurities and other particles on the surface of the steel plate to be stamped, and place the steel plate on the upper end of the lower template 24;

[0041] S4, stamping forming: after the steel plate in step S3 is placed, the left end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com