A kind of warping type thermosetting epoxy board and preparation method thereof

A thermosetting, warping technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of high cost, complicated process, unsatisfactory warping effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

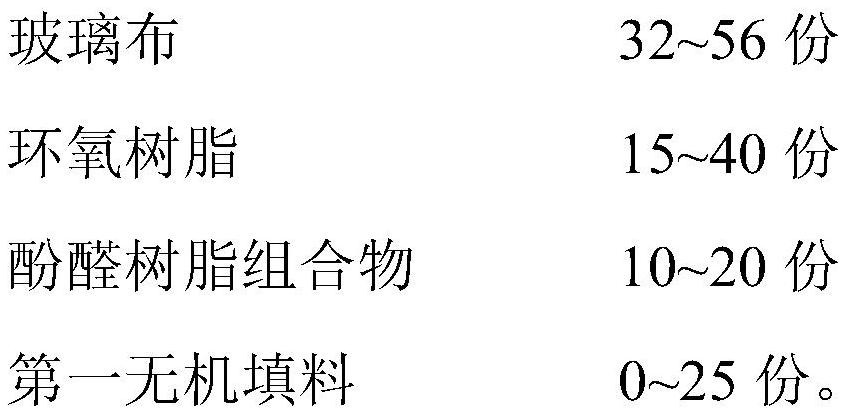

[0035] Get the first prepreg (conventional FR4 prepreg produced by our company, model WH3125, specification 7628RC445), quantity 1pcs, wherein, the first prepreg includes by weight: 55.5 parts of glass cloth, 24.5 parts of epoxy resin, phenolic resin composition 10 parts, 10 parts of the first inorganic filler.

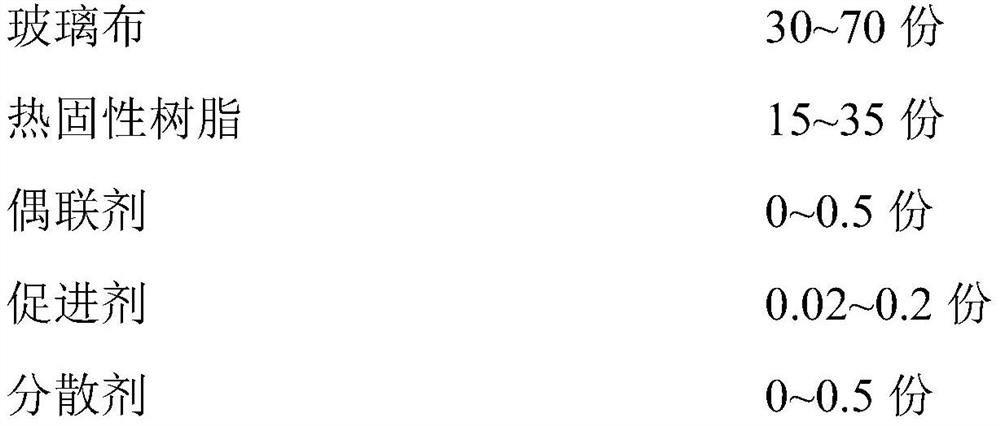

[0036] Take the second prepreg (lightweight prepreg produced by our company, model WH3127, specification 2116RC420), quantity 1pcs. Wherein, the second prepreg includes by weight: 58 parts of glass cloth, 21 parts of thermosetting resin, 0.5 part of coupling agent, 0.02 part of accelerator, 0.48 part of dispersant, and 22 parts of second inorganic filler.

[0037]Cut the first prepreg and the second prepreg into appropriate sizes, stack one first prepreg on one side, and one second prepreg on the other side, and stack them neatly to obtain a prepreg combination. Combine the pre-stacked prepregs, top and bottom Add a release film at a temperature of 170-200°C and a pr...

Embodiment 2

[0039] Take the first prepreg (conventional FR4 prepreg, model is WH3125, specification 2116RC450), quantity 2pcs, wherein, the first prepreg comprises by weight: 55 parts of glass cloth, 15 parts of epoxy resin, 20 parts of phenolic resin composition, the second 10 parts of an inorganic filler.

[0040] Take the second prepreg (lightweight prepreg, model WH3127, specification 1080RC680), quantity 1pcs. Wherein, the second prepreg includes by weight: 32 parts of glass cloth, 35 parts of thermosetting resin, 0.4 part of coupling agent, 0.2 part of accelerator, 0.4 part of dispersant, and 32 parts of second inorganic filler.

[0041] Cut the first prepreg and the second prepreg into appropriate sizes, stack two first prepregs on one side, and one second prepreg on the other side, and stack them neatly to obtain a prepreg combination. Combine the pre-stacked prepregs, top and bottom Add a release film at a temperature of 170-200°C and a pressure of 10-25kg / cm 2 Under the condit...

Embodiment 3

[0043] Take the first prepreg (conventional FR4 prepreg, model is WH3125, specification 1080RC680), quantity 2pcs, wherein, the first prepreg includes by weight: 32 parts of glass cloth, 28 parts of epoxy resin, 15 parts of phenolic resin composition, the second 1. 25 parts of inorganic filler.

[0044] Take the second prepreg (lightweight prepreg, model WH3127, specification 1080RC680), quantity 2pcs. Wherein, the second prepreg includes by weight: 32 parts of glass cloth, 32 parts of thermosetting resin, 0.3 part of coupling agent, 0.2 part of accelerator, 0.5 part of dispersant, and 35 parts of second inorganic filler.

[0045] Cut the first prepreg and the second prepreg into proper size, stack 2 first prepregs on one side, and stack 2 second prepregs on the other side, stack them neatly, add release film up and down, at a temperature of 170-200°C, Pressure 10~25kg / cm 2 Under the condition of hot pressing for 150min, 10Kgf / cm 2 The pressure is cold-pressed for 90 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com