Thin plate segment turning-over tool

A thin plate and tooling technology, which is applied in the field of thin plate segment turning tooling, can solve the problems of wasting materials, increased construction cycle and labor cost, and thin plate segment welding deformation, and achieves the effect of reducing the number of welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings. This embodiment is only used to explain the invention, and it cannot be assumed that the specific implementation of the present invention is only limited to these descriptions. For those of ordinary skill in the technical field of the present invention, without departing from the concept of the present invention, some simple deduction or replacement can be made, which should be regarded as belonging to the protection scope of the present invention.

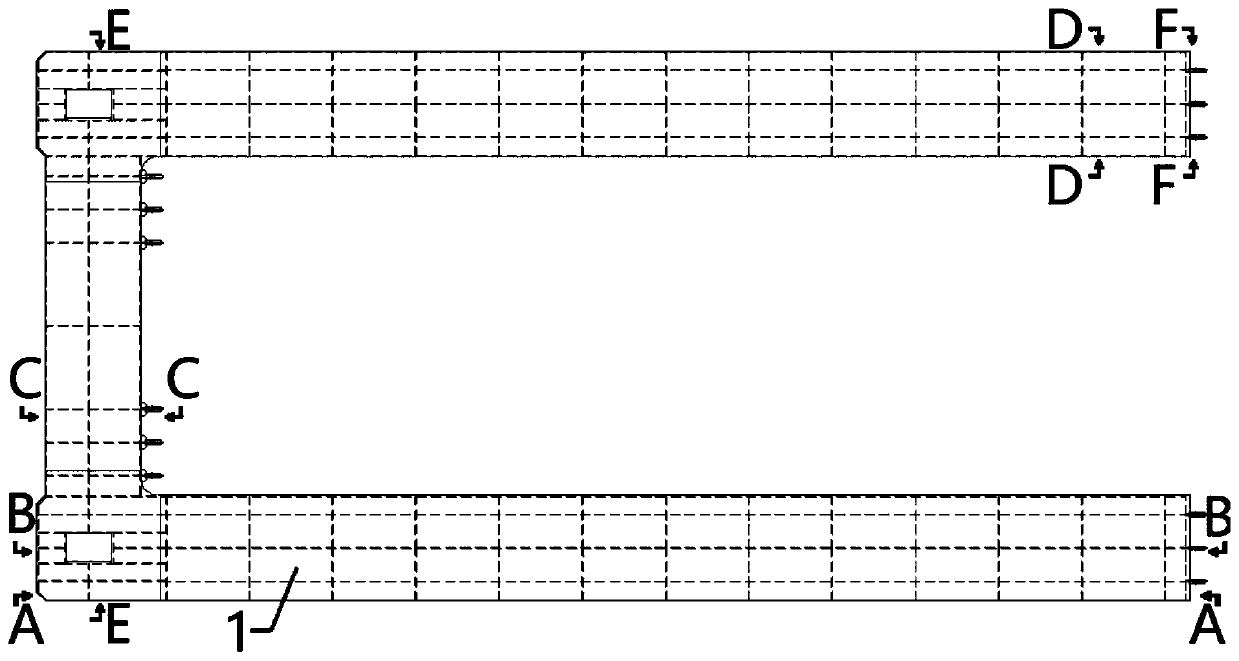

[0037] The invention provides a thin-plate section turnover tool, which is used to support the thin-plate section for turning operation. It mainly includes: a main beam 10, a support beam 20 and three supports 30 supporting it.

[0038] refer to Figure 1 to Figure 7 The structure of the main girder is shown. It is set as a U-shaped closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com