A general-purpose thermal insulation slat integrated lamination device

A thermal insulation slat, general-purpose technology, applied in the field of balers, can solve the problems of uneven stacking, affecting the packaging work, time-consuming and labor-intensive work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

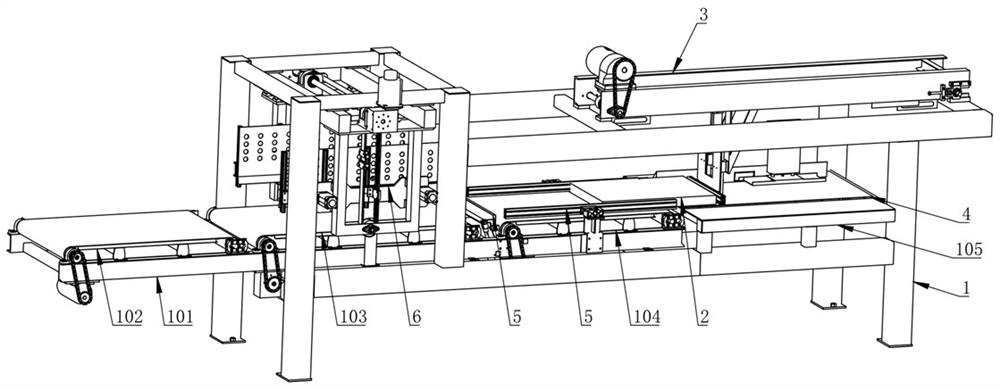

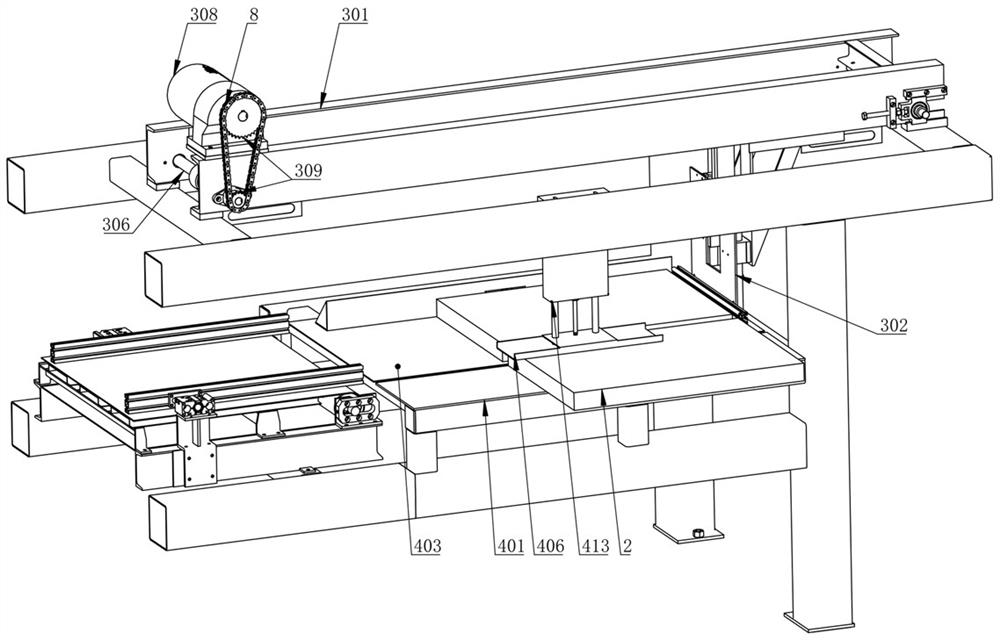

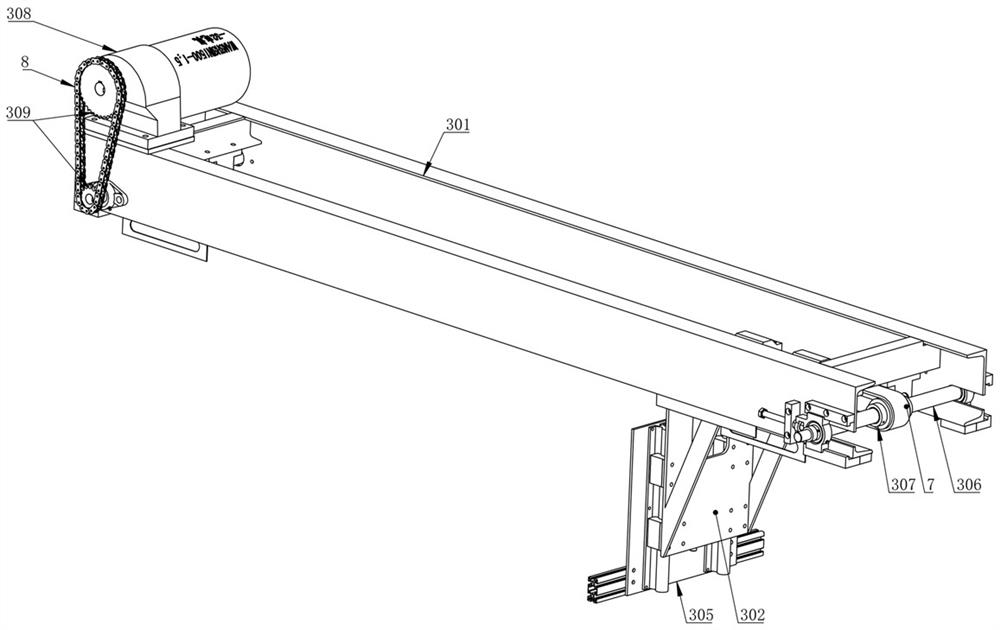

[0030] Specific implementation mode one: combine Figure 1-14As shown, a general-purpose thermal insulation slat integrated lamination device is characterized in that it includes a main frame 1, rock wool 2, a pushing device 3, a separation and pressing device 4, a calibration limit device 5, and a stacking and stacking device 6 , synchronous belt 7 and chain 8; the left side of the middle position inside the main frame 1 is fixed with a support frame 101; the top of the support frame 101 is sequentially installed with a stacked conveyor belt 102, a stacking conveyor belt 103 and a calibration conveyor belt 104 from left to right The inside of the main frame 1 is provided with a bracket 105 at the right end of the support frame 101; the separation and pressing device 4 is arranged on the top of the bracket 105; the pushing device 3 is installed at the position above the separation and pressing device 4; Between the stacking conveyor belt 103 and the calibration conveyor belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com