A large transmission ratio reduction method and device

A technology of large transmission ratio and reduction gear, applied in the direction of transmission, gear transmission, transmission parts, etc., can solve the problems of large size, high cost, short life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

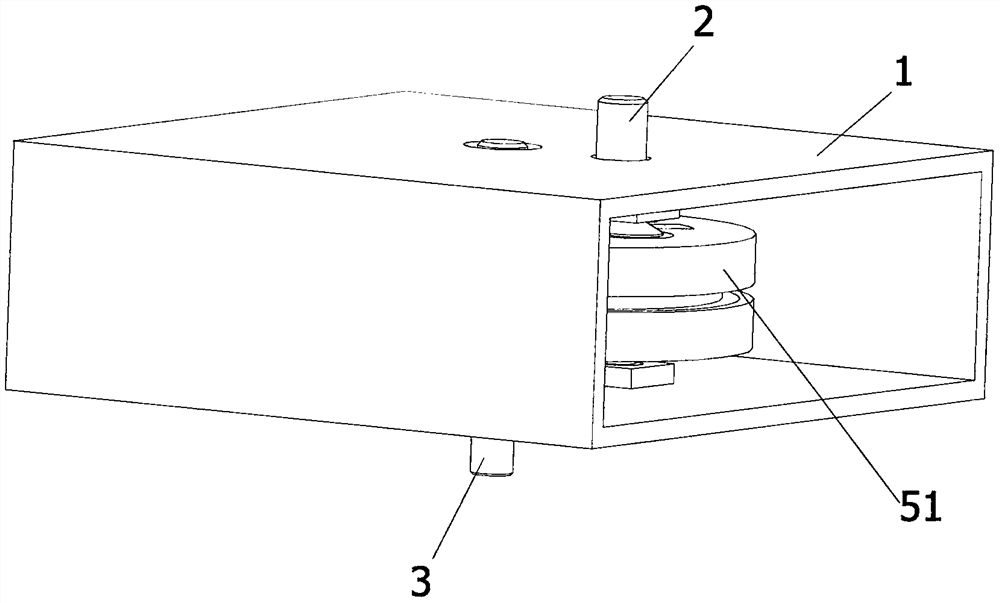

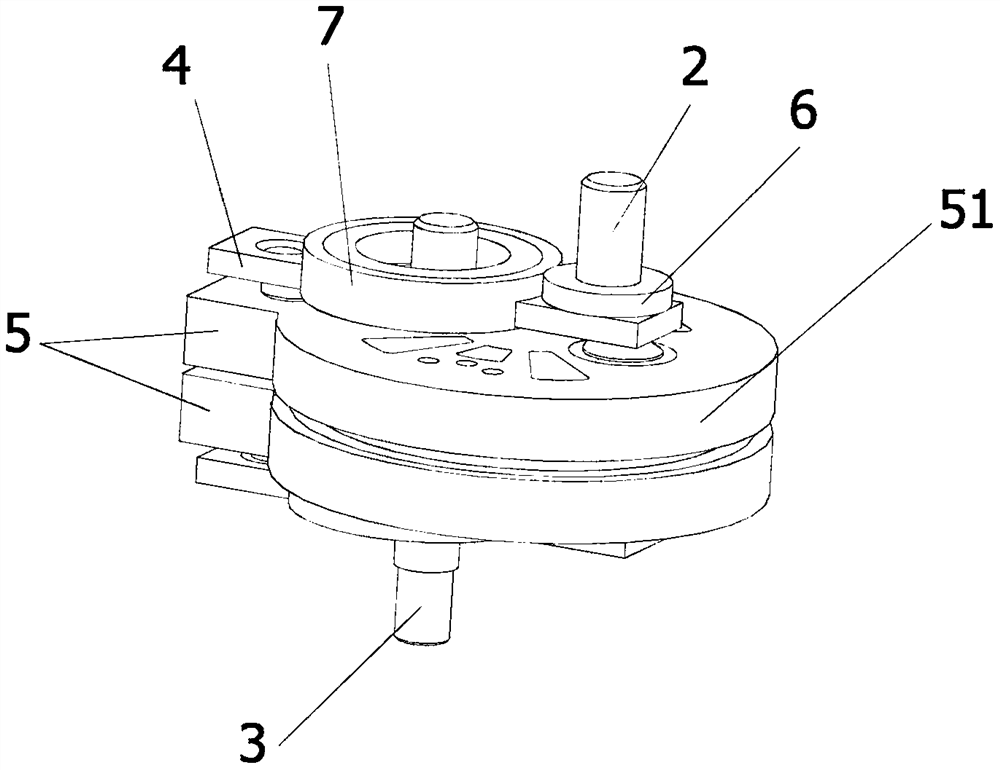

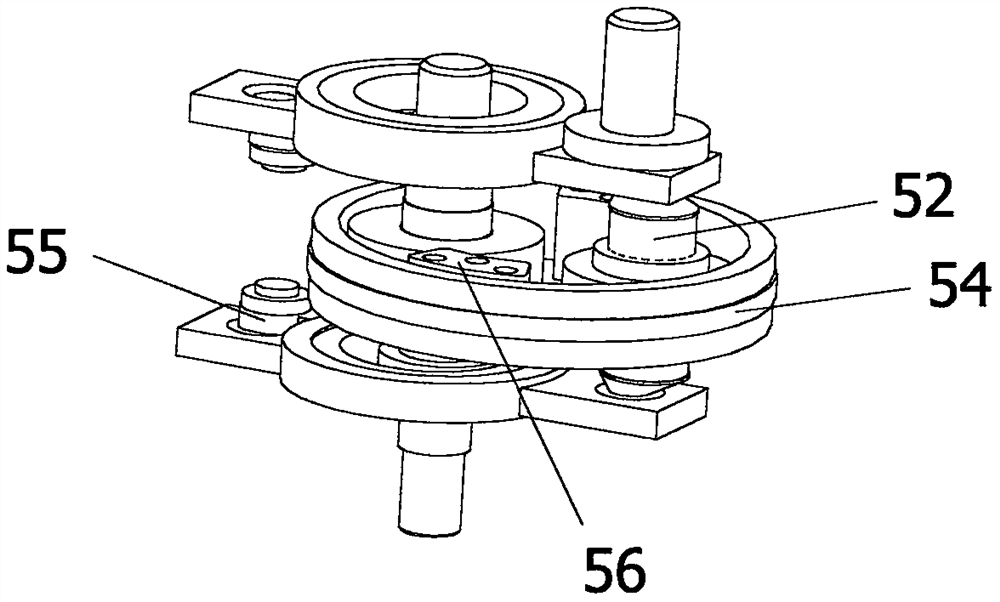

[0049] Such as Figure 1~4 As shown, a large transmission ratio reduction device, including a box 1;

[0050] an input shaft 2, the input shaft 2 is rotatably arranged on the box body 1;

[0051] an output shaft 3, the output shaft 3 is rotatably arranged on the box body 1;

[0052] The first turret 4, the first turret 4 is rotatably arranged on the box body 1, the rotating shaft of the first turret 4 around the box body 1 and the output shaft 3 around the box body 1. The rotating shafts are not on the same axis;

[0053] The first transmission group 5 , the first transmission group 5 is arranged on the first turret 4 , and the first transmission group 5 is used to link the first turret 4 and the output shaft 3 .

[0054] In this embodiment, the input shaft 2 and the first turret 4 are installed on the box body 1, power is input through the input shaft 2, and the input shaft 2 is fixedly arranged on the first turret 4 through the second gear 6 fixedly connected thereto. Th...

Embodiment 2

[0067] Such as Figure 5-9 As shown, a large transmission ratio reduction device, including a box 1;

[0068] an input shaft 2, the input shaft 2 is rotatably arranged on the box body 1;

[0069] An output shaft 3, the output shaft 3 is rotatably arranged on the box body 1, and the output shaft 3 and the input shaft 2 are not coaxially arranged on the box body 1;

[0070] The second turret 91, one side of the second turret 91 is rotatably arranged with the box body 1, and the other side of the second turret 91 is rotatably connected with the input shaft 2;

[0071] The third turret 92, one side of the third turret 92 is rotatably arranged on the box body 1, the other side of the third turret 92 is rotatably arranged with the output shaft 3, the third turret 92 is not coaxial with the rotating shaft of the casing 1 and the rotating shaft of the second turret 91 and the casing 1;

[0072] The second ring gear 10 , the second ring gear 10 is fixedly arranged on the casing 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com