Extractor hood adjustable in air inlet area and control method thereof

A range hood and air intake area technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of wasting energy, wasting the extraction potential of the hood, and poor user experience, so as to achieve efficient oil fume suction, Improve the user experience and change the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

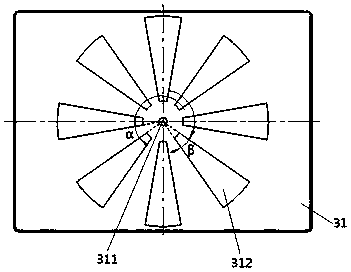

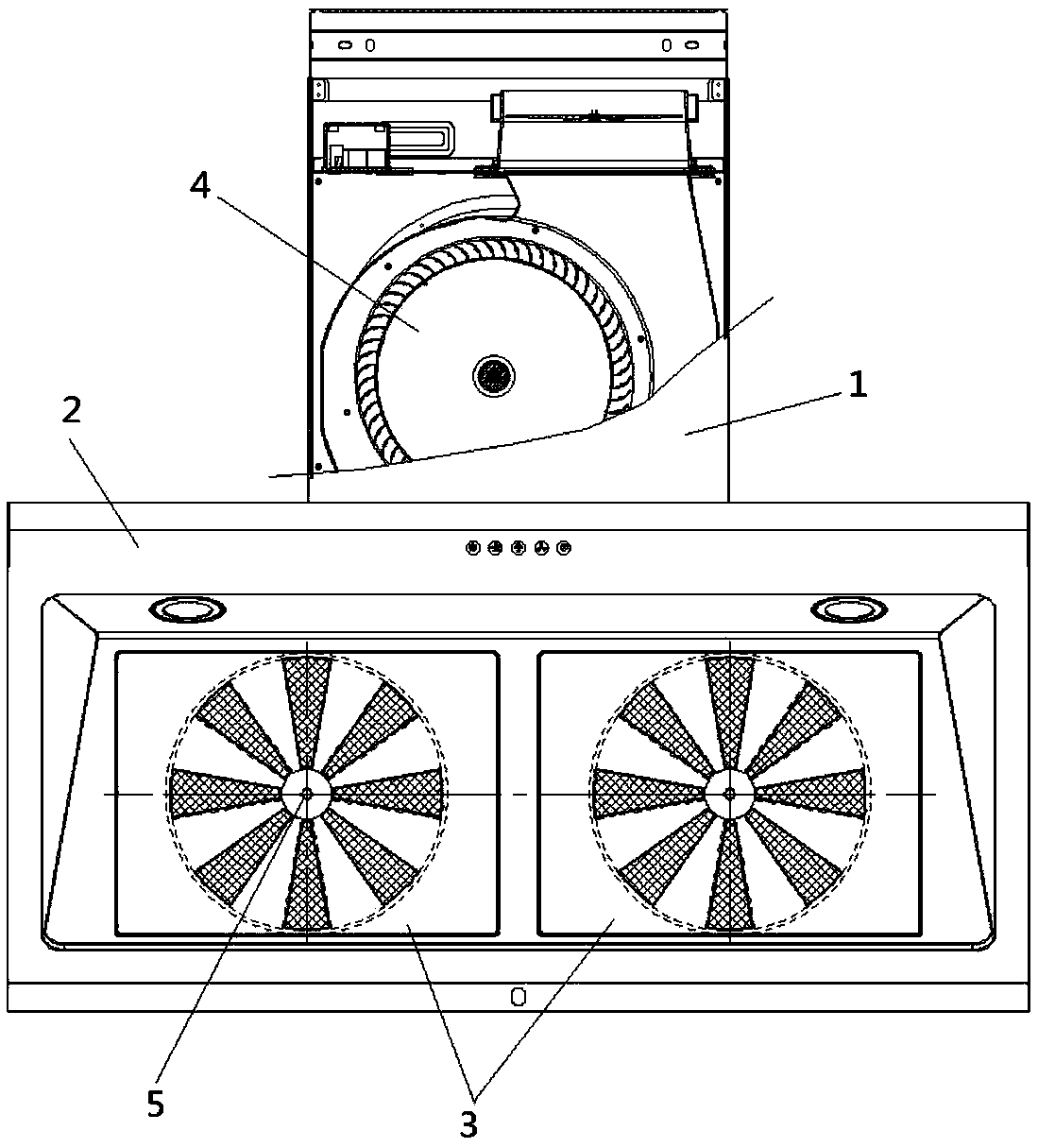

[0032] Embodiment 1 of the present invention provides a range hood with adjustable air intake area, such as figure 1 and 2 As shown, it includes a box body 1, a smoke collection hood 2, an oil screen structure 3, a fan 4, a sensor 5 and a controller. The air inlet and the right air inlet, the left air inlet and the right air inlet are all equipped with an oil grid structure 3, the fan 4 and the controller are both installed in the box body 1, the sensor 5 is installed on the oil grid structure 3, and the controller is respectively connected to the oil grid The structure 3 is connected to the sensor 5, and is used to adjust the air intake area of the oil net structure 3 according to the concentration of oil smoke collected by the sensor 5.

[0033] The oil net structure 3 includes at least two layers of oil nets arranged inside and outside, at least two layers of oil nets are provided with relative air inlets, and the oil nets located in the inner layer are rotated to change...

Embodiment 2

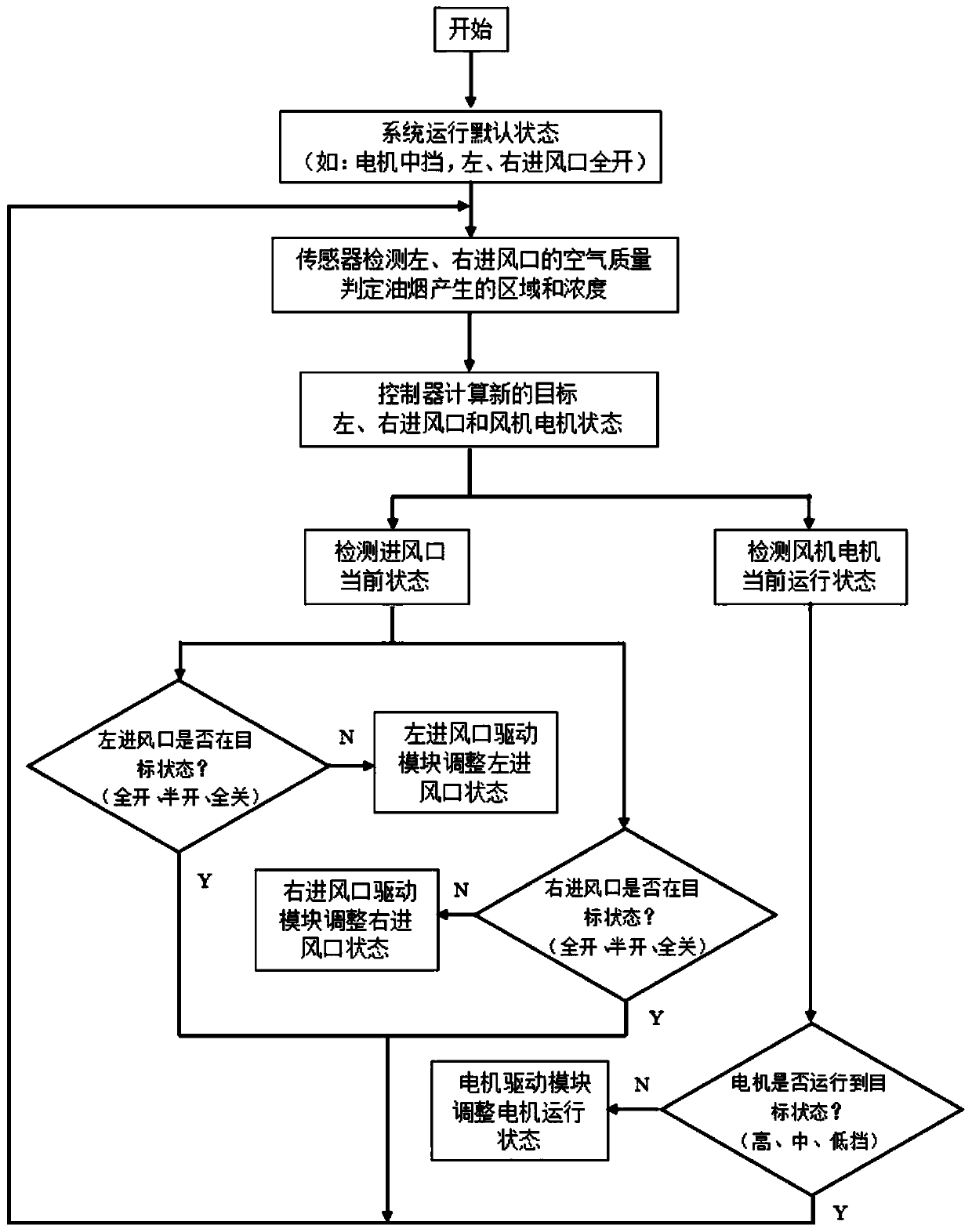

[0049] Embodiment 2 of the present invention provides a control method for a range hood, which is applied to the range hood with adjustable air intake area as described in Embodiment 1, and its control flow chart is as follows Figure 10 As shown, the range hood starts to operate with the oil net structure fully open; the sensor detects the concentration of the oil fume at the left air inlet and the right air inlet of the range hood in real time; the controller collects the concentration of the oil fume at any air inlet according to the sensor The concentration adjusts the air inlet area of the oil net structure at the air inlet.

[0050] Wherein, the controller adjusts the air intake area of the oil net structure at the air inlet according to the concentration of oil fume collected by the sensor at any air inlet, specifically: the controller determines the concentration of oil fume at any air inlet according to the sensor. Whether oil fume is generated at the air inlet, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com