Multilayer mesh belt type drying machine for plywood manufacturing

A mesh belt dryer, plywood technology, applied in progressive dryers, dryers, drying of solid materials, etc., can solve the problems of insufficient drying degree, large floor space, complicated operation, etc., to improve comprehensiveness, The effect of avoiding local degumming and reducing cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

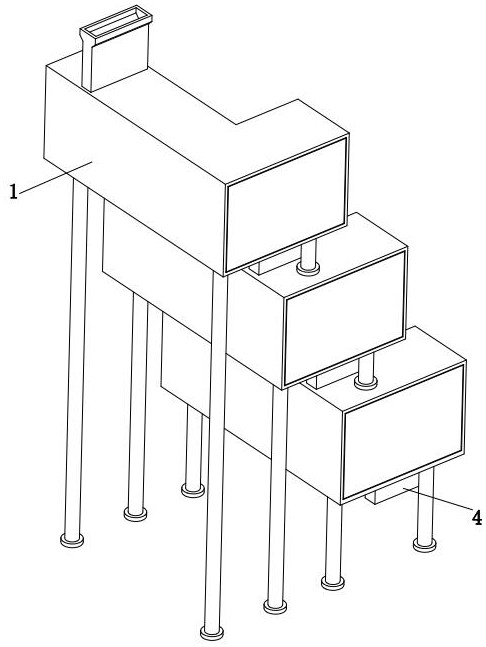

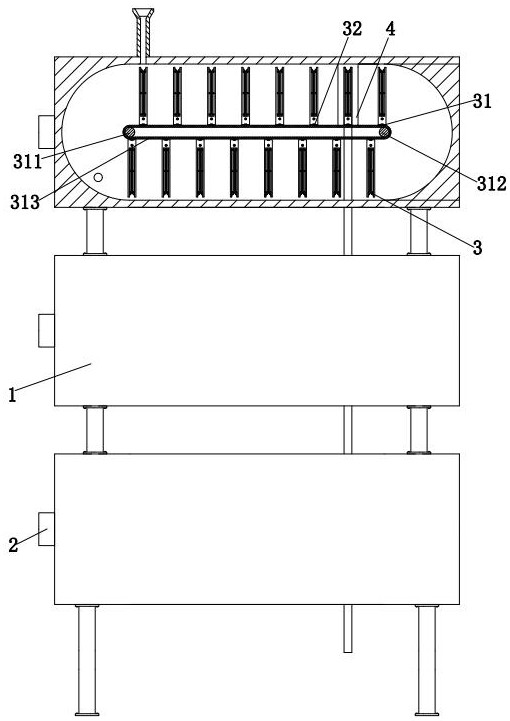

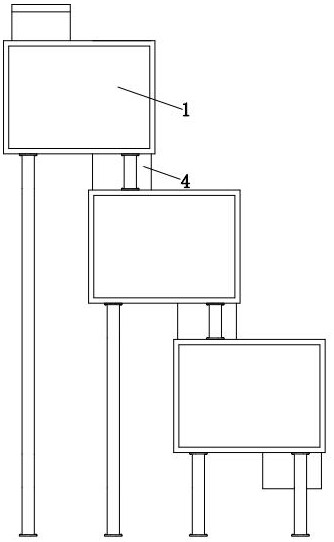

[0033] refer to figure 1 , figure 2 and image 3 , a multi-layer mesh belt dryer made of plywood, comprising a drying shell 1, a hot air blower 2, a feeding device 3 and a feeding device 4, the number of the drying shells 1 is three, and the three drying shells 1 are from It is distributed in steps from top to bottom. The top view of the drying shell 1 is a horizontal L-shaped structure to reduce the occupied area. The left and right ends of the inner cavity of the drying shell 1 are semicircular structures. Be a rectangular structure, the distance between the inner wall of the drying shell 1 and the surface of the conveying mesh belt 313 is greater than the height of the material rack, less than 1.5 times the height of the material rack, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com