Anti-powder residue sampling equipment using vibration for sampling concrete powder

A technology of concrete powder and sampling equipment, which is applied in sampling, sampling device, analyzing materials, etc., can solve problems such as affecting the accuracy of sample detection results and sample residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

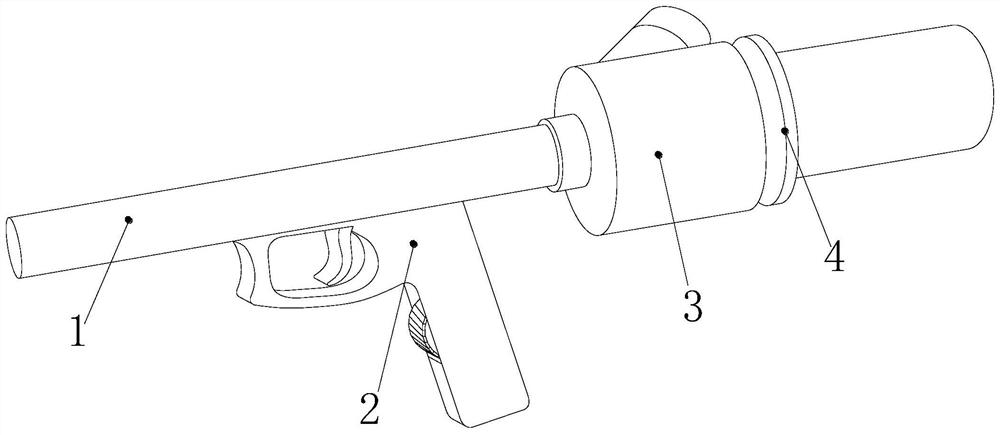

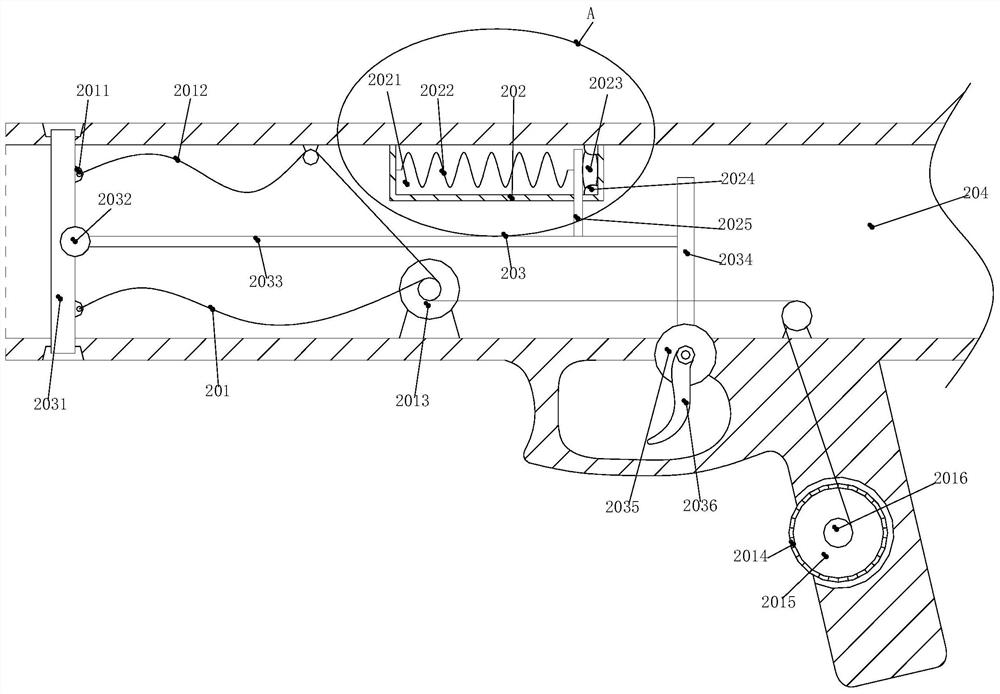

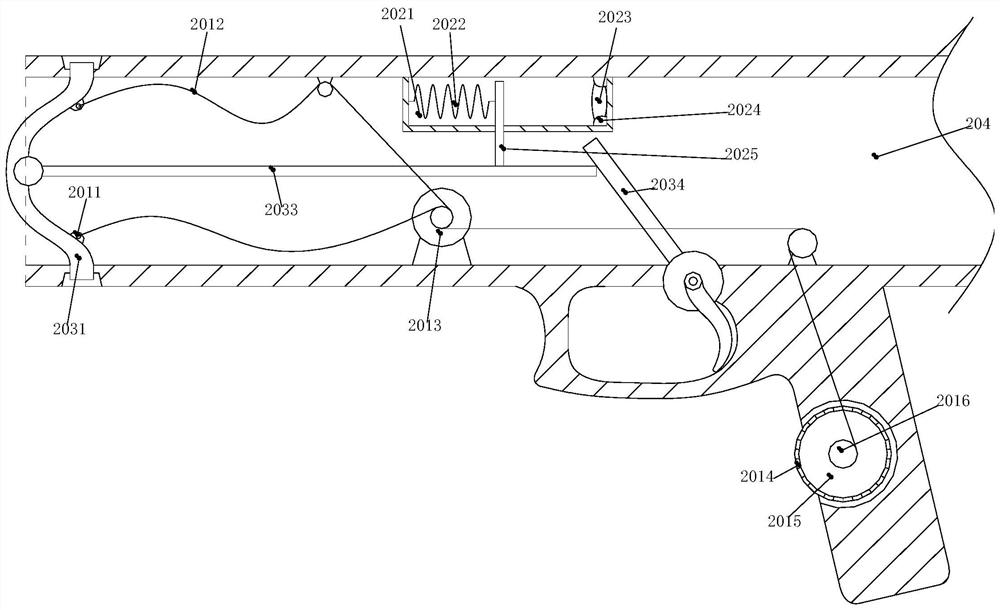

[0024] see Figure 1-Figure 5 , the present invention provides the anti-powder residual sampling equipment using shaking for concrete powder sampling, its structure includes sampling pipe 1, sampling device 2, shell 3, connecting pipe 4, described sampling pipe 1 is connected with sampling device 2 , the sampling device 2 is installed in the shell 3, the shell 3 is mechanically connected with the connecting pipe 4, the connecting pipe 4 is arranged on the end of the shell 3 away from the sampling device 2, the sampling device 2 Connect with case 3.

[0025] The sampling device 2 is composed of a shaking mechanism 201, a sampling mechanism auxiliary device 202, a sampling mechanism 203, and a working chamber 204. The described shaking mechanism 201 cooperates mechanically with the sampling mechanism auxiliary device 202, and the described sampling mechanism 203 and the sampling mechanism The auxiliary device 202 is mechanically connected, the sampling mechanism auxiliary devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com