Vacuum sampling device and sampling method

A sampling device, vacuum technology, applied in the direction of sampling devices, etc., to achieve significant beneficial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

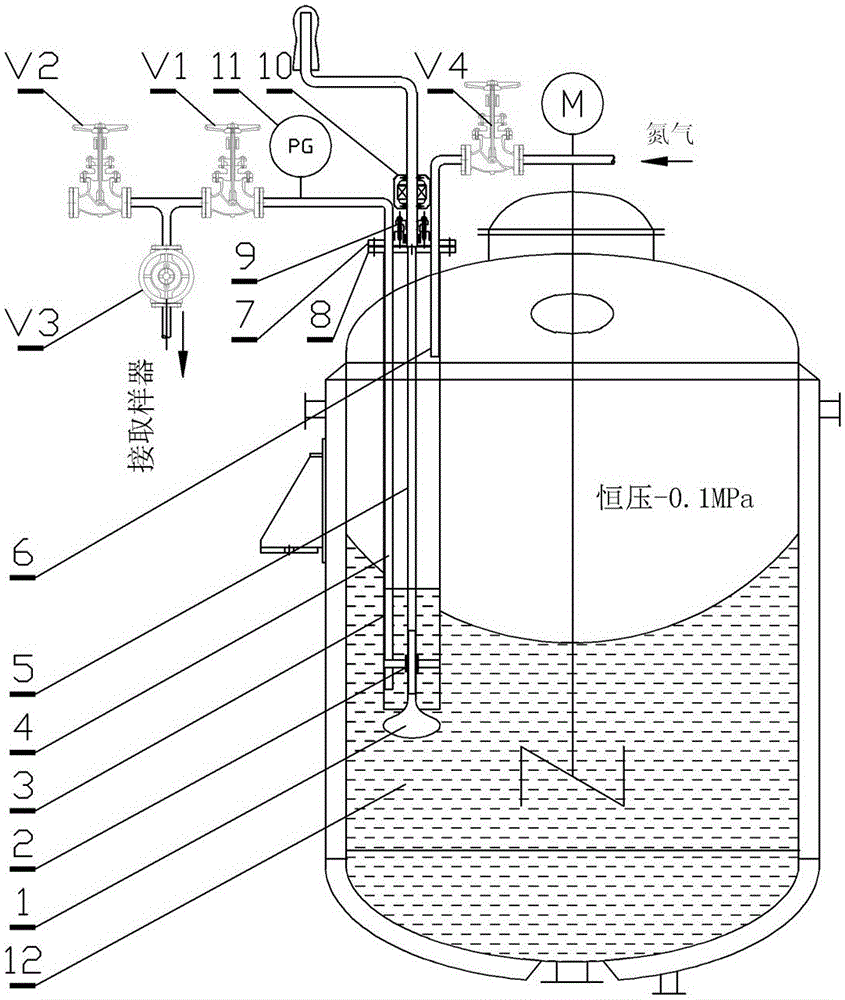

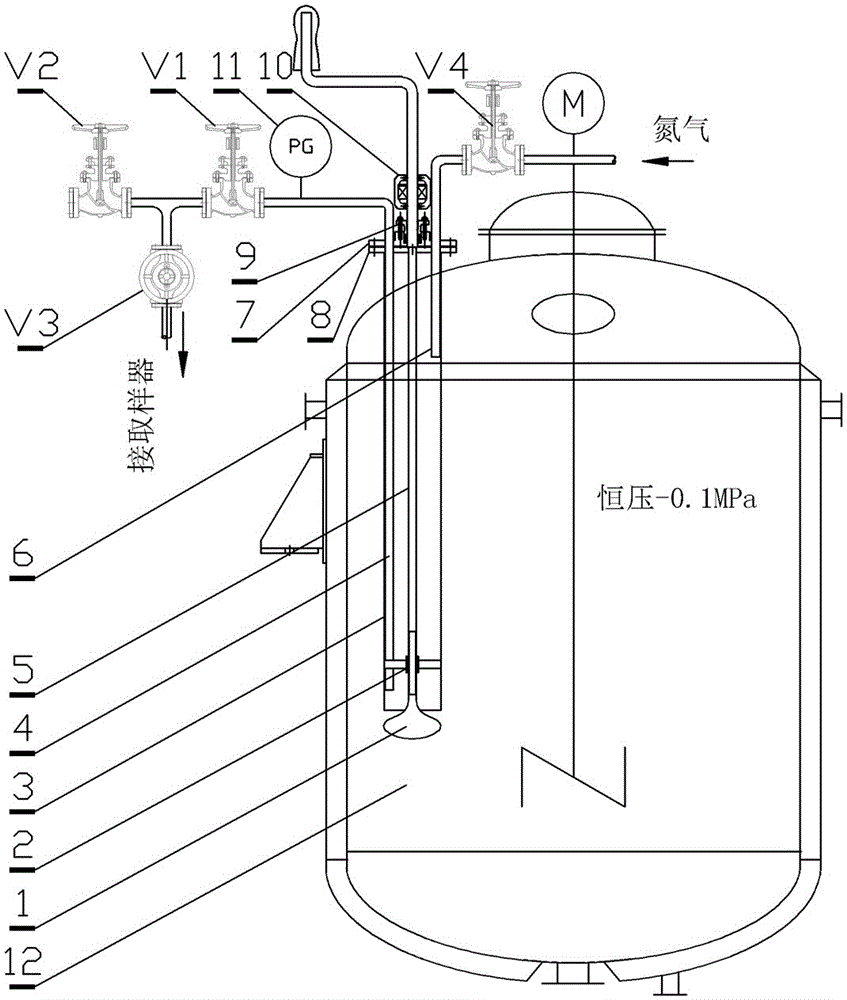

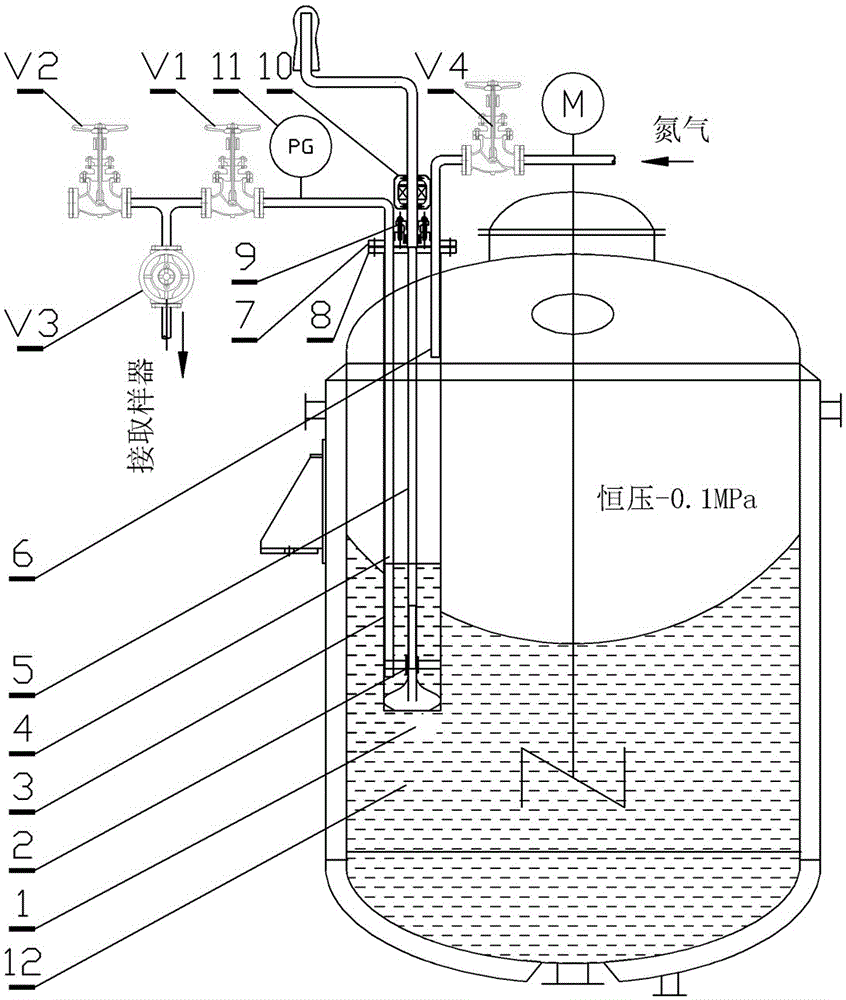

[0020] Such as figure 1 As shown, a structural schematic diagram of the vacuum sampling device of the present invention is given, which consists of a sampling barrel 3, a rocker arm 5, a sampling tube 4, an inflation tube 6, a rocker arm support frame 2, a rubber plug 1, a stuffing box 7, and a bearing seat 10 and valves V1, V2, V3, and V4. The lower end of the sampling barrel 3 shown is open and extends into the reactor body 12, so that the material in the reactor body 12 enters the sampling barrel 3, the sampling barrel 3 The depth of penetration should not affect the operation of the stirring device. The illustrated sampling tube 4 is located in the sampling barrel 3, the diameter of the sampling tube 4 is smaller than the diameter of the sampling barrel 3, and the inflation tube 6 is also located in the internal cavity of the sampling barrel 3. The lower end openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com