Patents

Literature

48results about How to "Will not affect the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

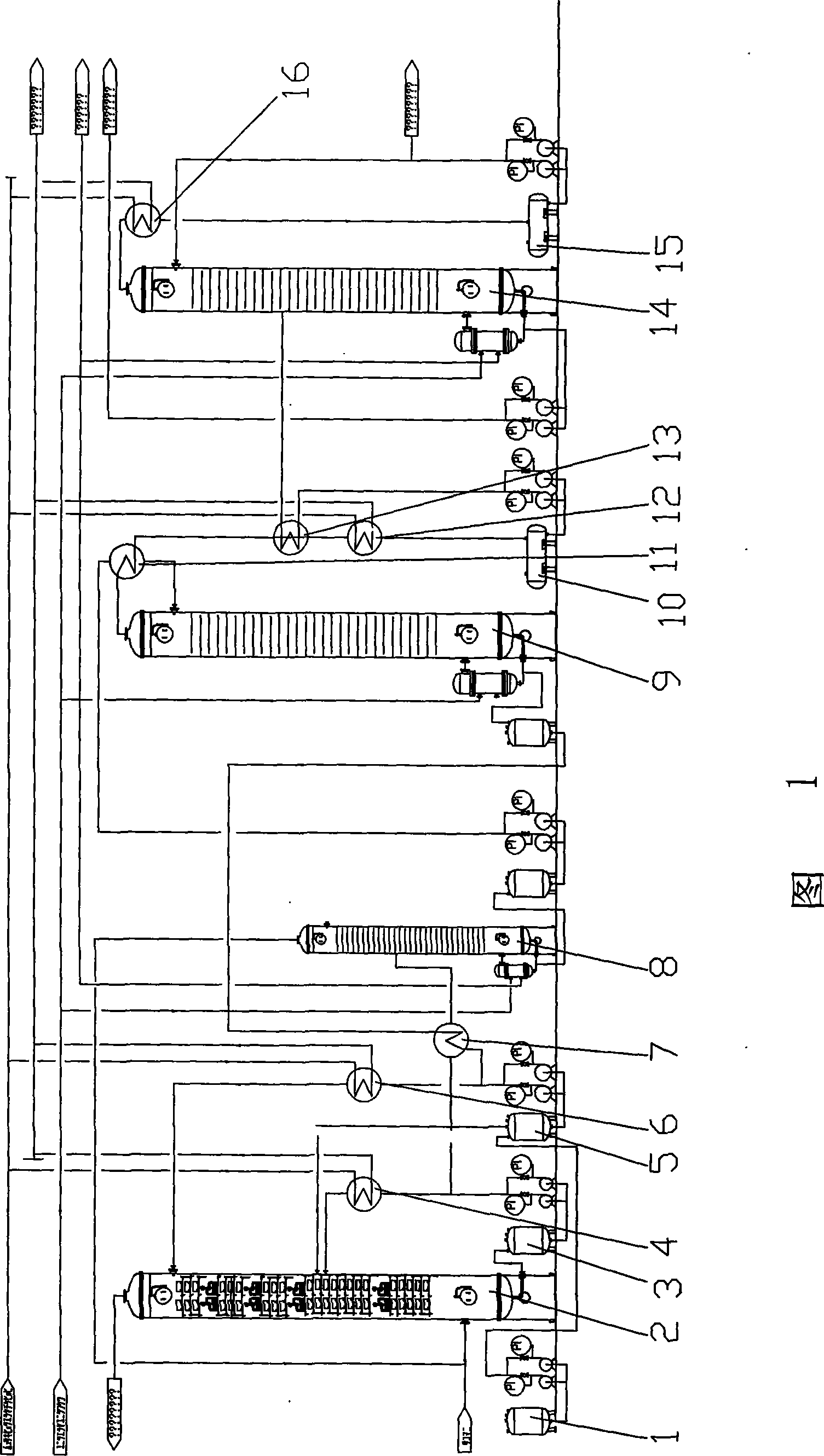

Ammonia recovery method for gas mixture in hydrogen cyanide production

ActiveCN101264901AAvoid lossReduce manufacturing costHydrogen cyanide preparation/purification/separationAmmonia preparation/separationRecovery methodDesorption

The invention discloses an ammonia recovery method from the mixing gas produced in the process of hydrogen cyanide production, comprising ammonia absorption process, decyanation process, desorption process and rectifying process for solving the technical problem. The invention is characterized in that decyanation process is set separately to recovery hydrogen cyanide gas, avoiding the loss of hydrogen cyanide caused by a large amount of acid gas like hydrocyanic acid contained in the ammonium phosphate solution directly steamed in Versum method, reducing production cost of hydrogen cyanide, reducing the emission of the harmful acid gas like hydrogen cyanide, and avoiding the serious pollution of peripheral enviroment. Besides, the ammonium phosphate solution contains a much smaller amout of hydrocyanic acid after hydrogen cyanide is recovered, which can not influence production process and make the production process more safety.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

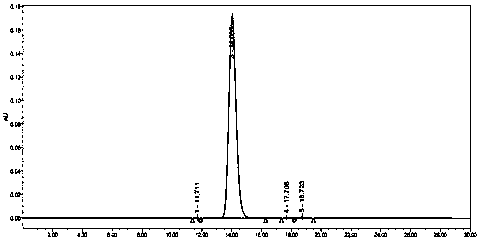

Glass coating and film technology for reducing platinum rhodium alloy bushing plate loss

InactiveCN102352143AReduce volatilityWill not affect the production processPretreated surfacesCoatingsPlatinumMetallurgy

A glass coating for reducing platinum rhodium alloy bushing plate loss provided by the invention comprises glass and Suzhou soil in a mass ratio of 9-15:1; a film technology employs a sol-gel film method, which is simple; and the coating raw material is cheap and with a utilization rate. Small size (nanometer level) oxide particles with high specific surface area and high activity can be obtained; and the coating has high uniformity, and multiple ingredient uniform oxide coating is easily prepared.

Owner:UNIV OF JINAN

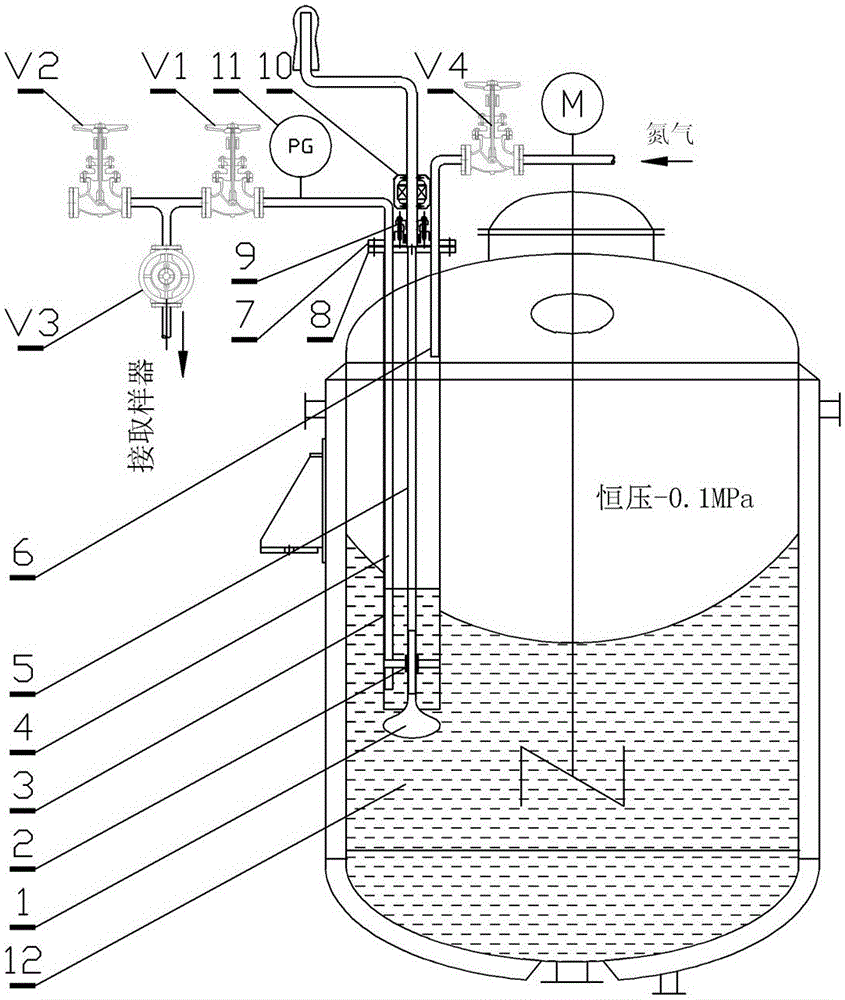

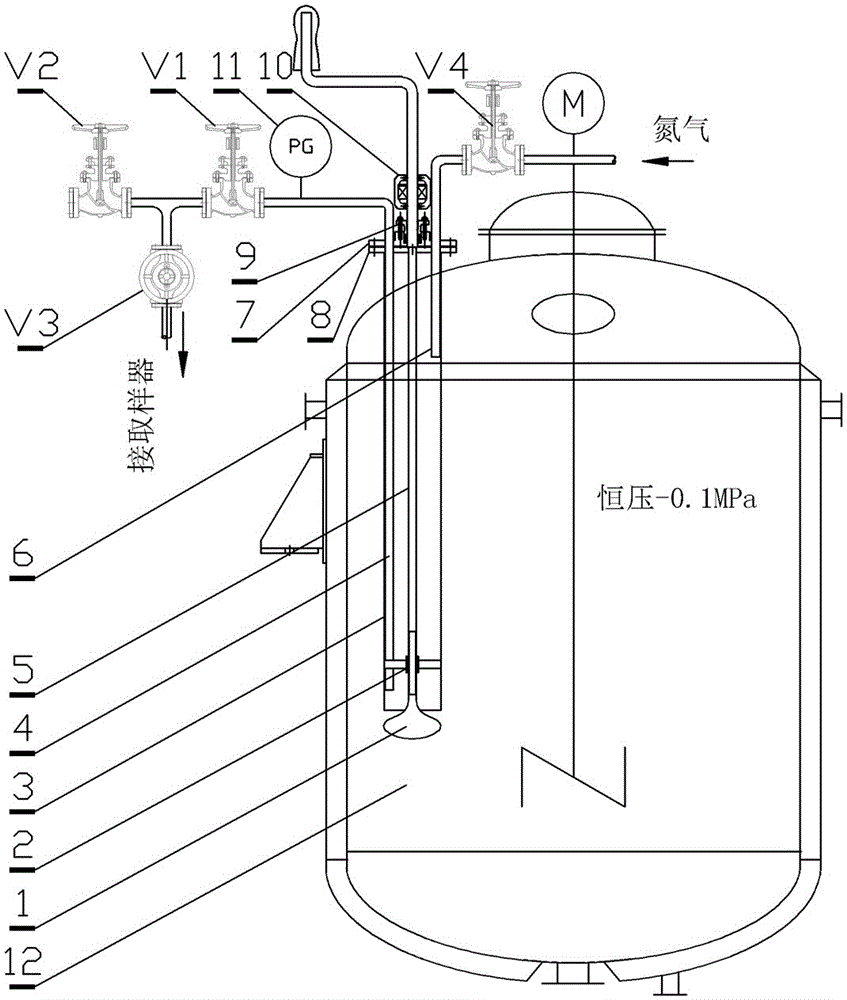

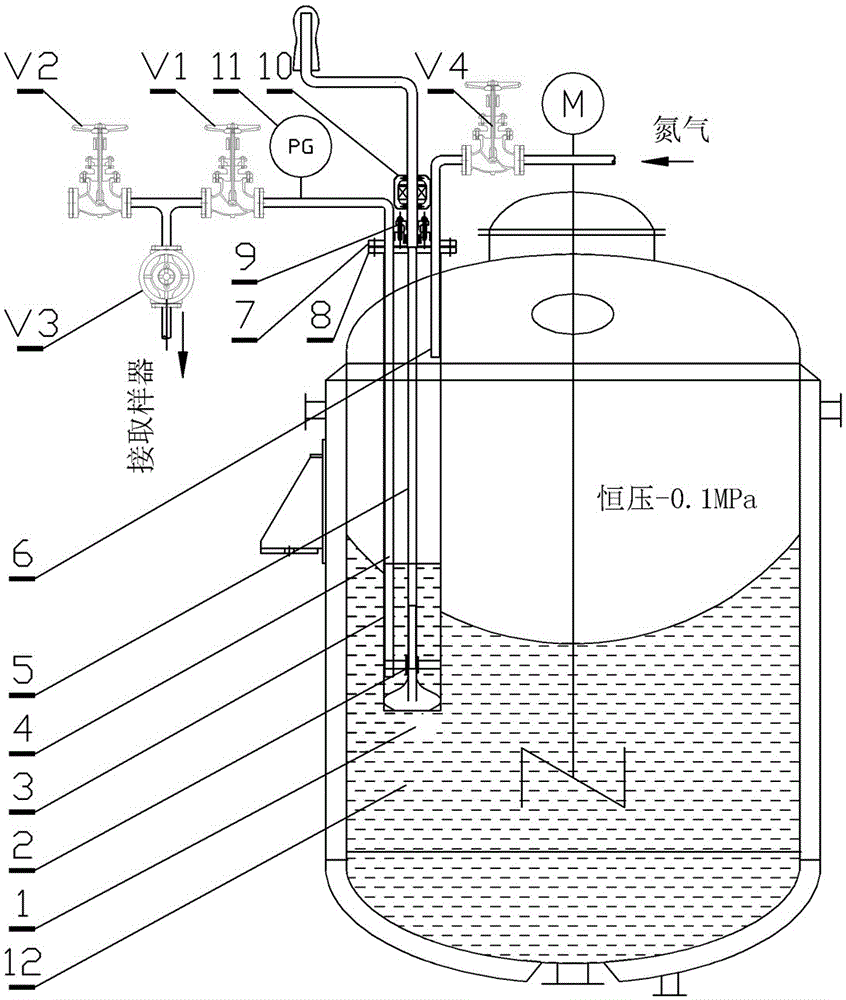

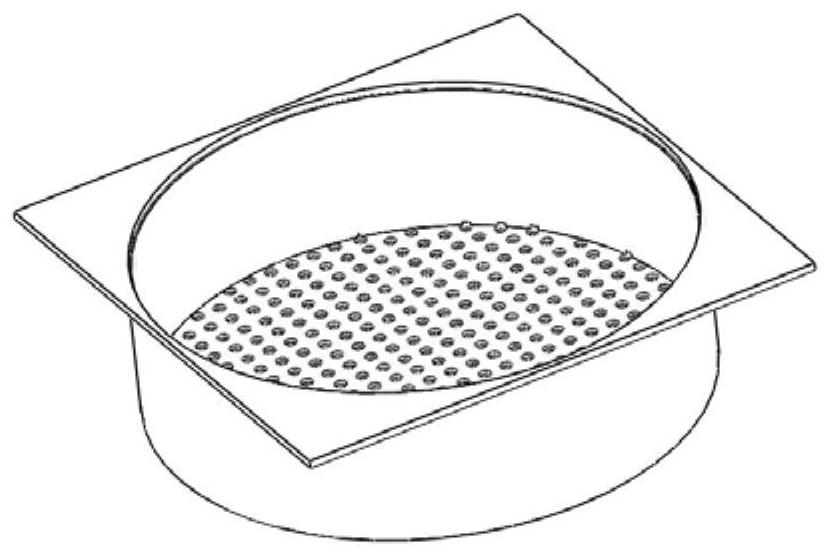

Vacuum sampling device and sampling method

ActiveCN105092282ASampling implementationAchieve isolationWithdrawing sample devicesPositive pressureGas-filled tube

A vacuum sampling method comprises the steps: under a condition of keeping a negative pressure in a kettle body of a reaction kettle, allowing a sampled material to enter a sampling container; followed by, closing the sampling container, then injecting inert gas to discharge the sampled material, and thus realizing sampling. A vacuum sampling device includes a sampling barrel, a sampling tube, a rocker arm and a gas-filling tube; the sampling barrel stretches into the kettle body of the reaction kettle and has the lower end opening, the sampling tube and the gas-filling tube are both located in the sampling barrel, the rocker arm is located in the sampling barrel and is in coaxial arrangement with the sampling barrel, the lower end of the rocker arm is fixedly provided with a rubber plug which can seal the opening of the lower end of the sampling barrel. According to the vacuum sampling device and the sampling method, the sampling barrel and the reaction kettle are isolated through the rubber plug; through injection of the inert gas, a negative pressure state of the sampling barrel is changed into a positive pressure state, the material is sampled, in the whole sampling process, the kettle body of the reaction kettle still remains the vacuum (negative pressure) state, the pressure condition is not changed, and the production process is not affected; and beneficial effects are remarkable, and the device and the method are suitable for application.

Owner:SHANDONG WEIFANG RAINBOW CHEM

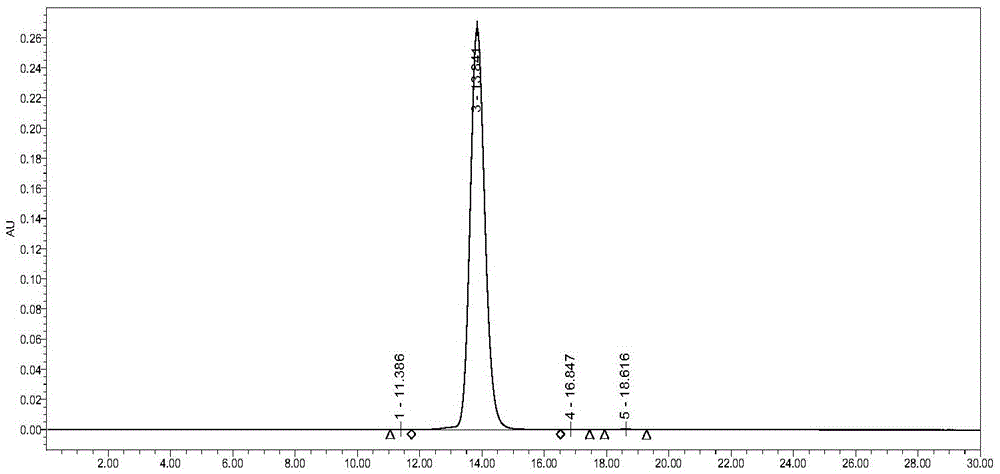

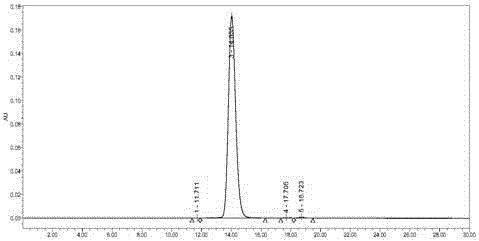

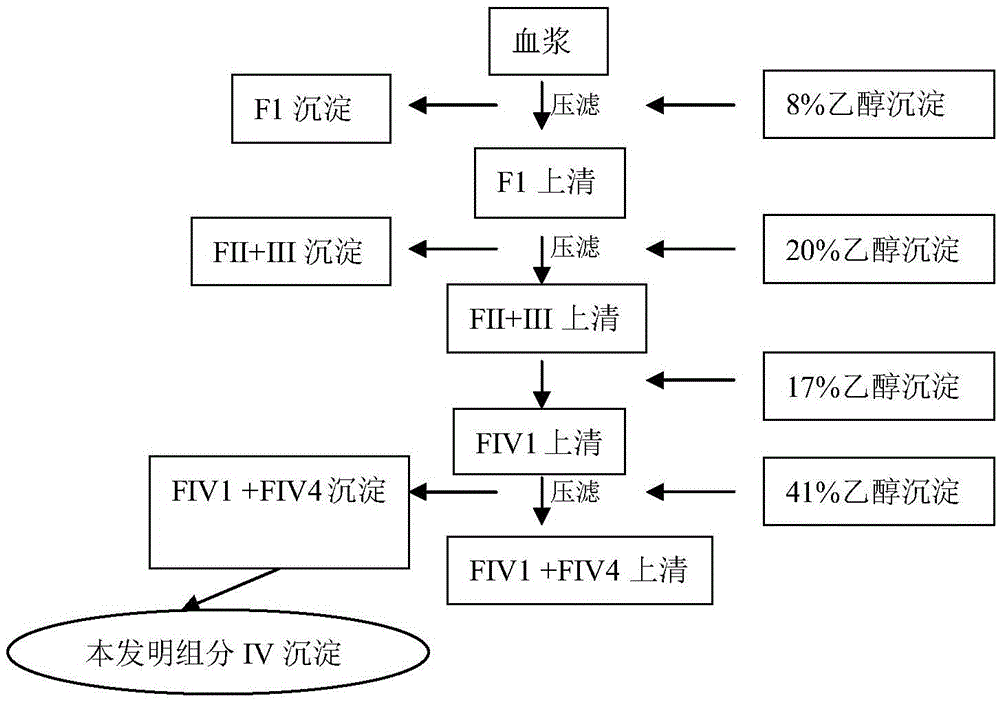

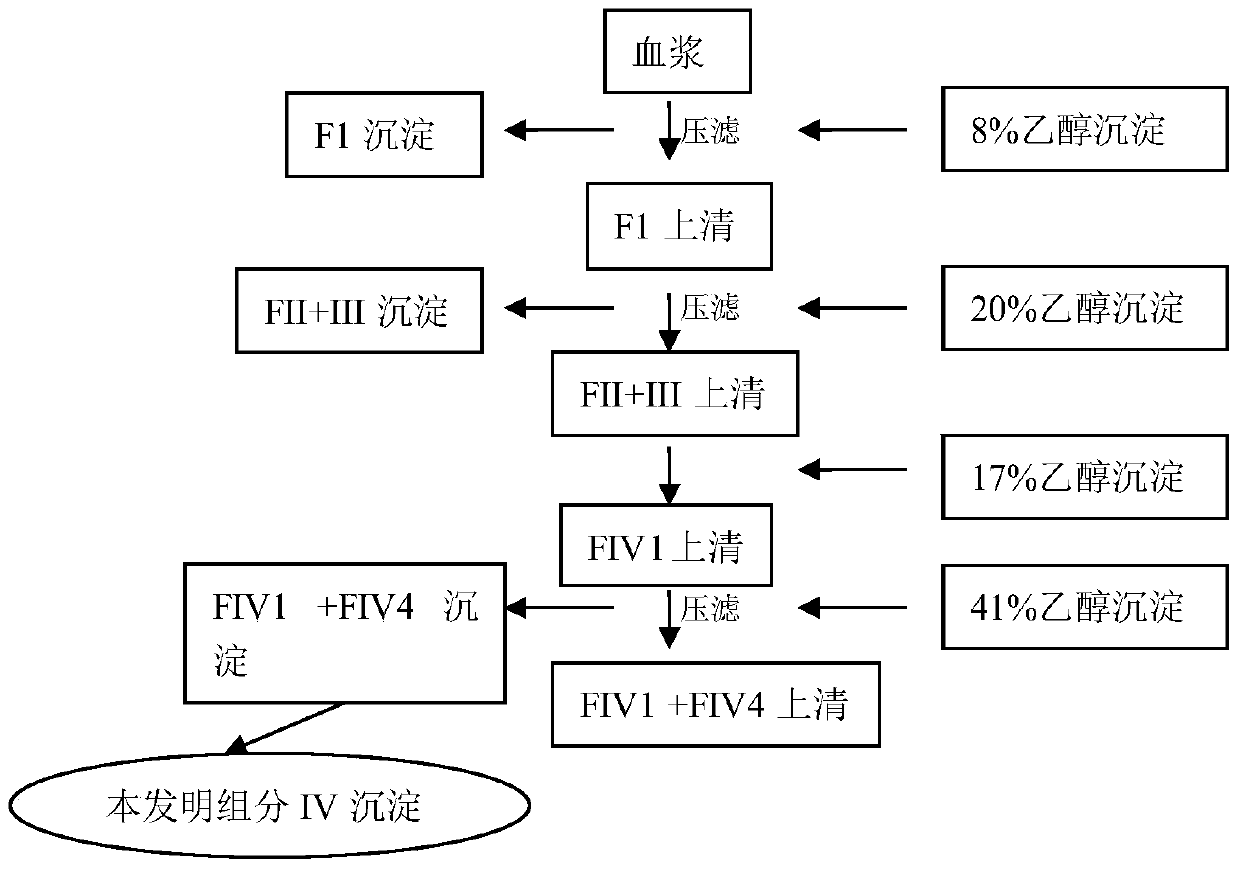

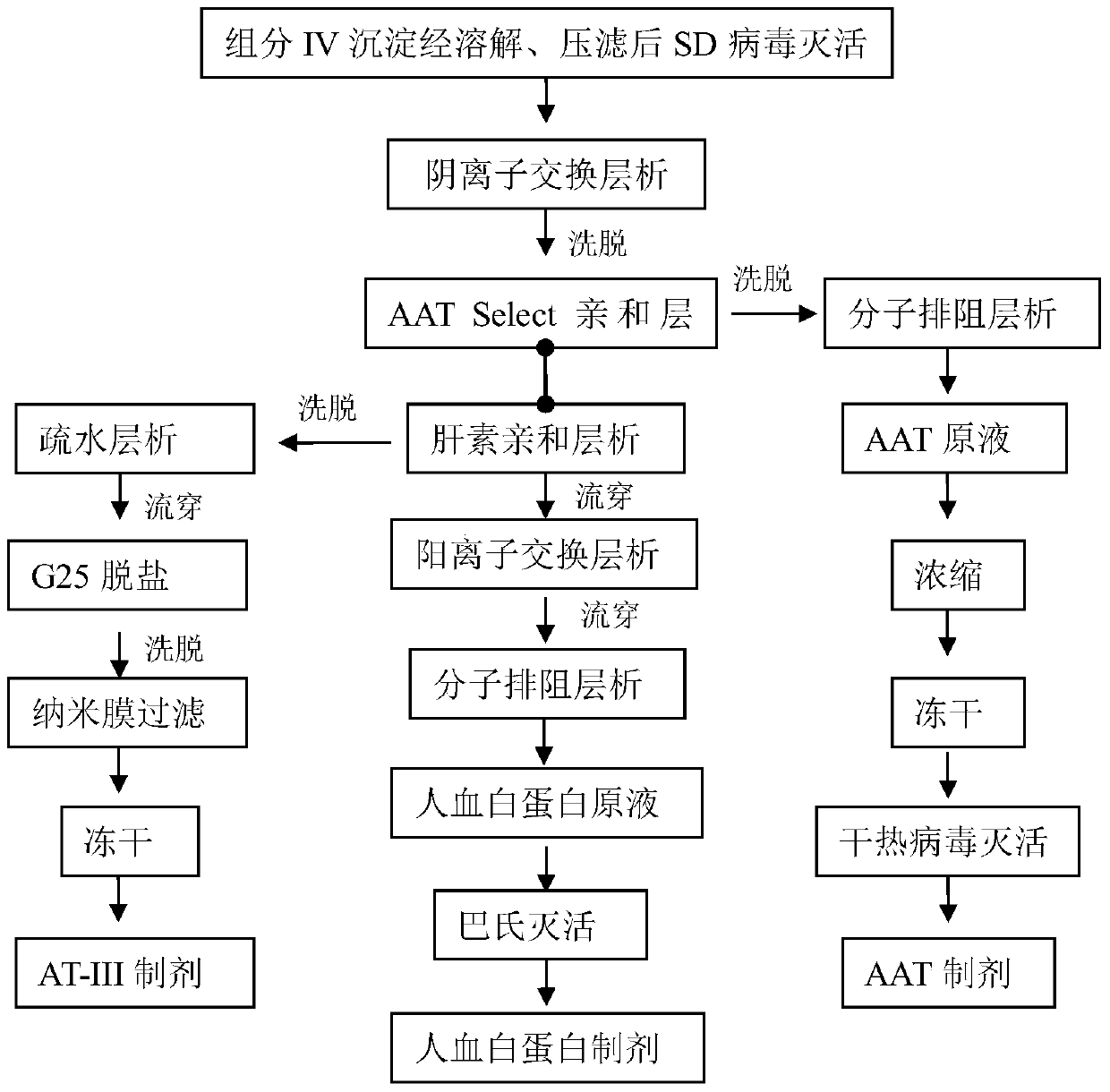

Method for extracting antithrombase III and multiple kinds of functional protein from plasma Cohn method component IV sediment

ActiveCN105669858ARaise quality standardsHigh quality attributeSerum albuminPeptide preparation methodsBlood plasmaSediment

The invention provides a method for extracting antithrombase III from Cohn method component IV sediment. According to the method, AT-III with the purity approximate to 100% can be extracted, and compared with an existing method, the specific activity and yield are remarkably increased. In addition, the invention provides a method for comprehensively extracting and utilizing alpha1-antitrypsin, antithrombase III and albumin from the Cohn method component IV sediment. Separation and extraction of the three products are achieved on the same process line at the same time, the production cost of alpha1-antitrypsin and antithrombase III can be effectively reduced, and large-scale industrial production can be achieved. According to the method, the comprehensive utilization efficiency of plasma can be remarkably improved, and high application value is achieved.

Owner:LANZHOU INST OF BIOLOGICAL PROD

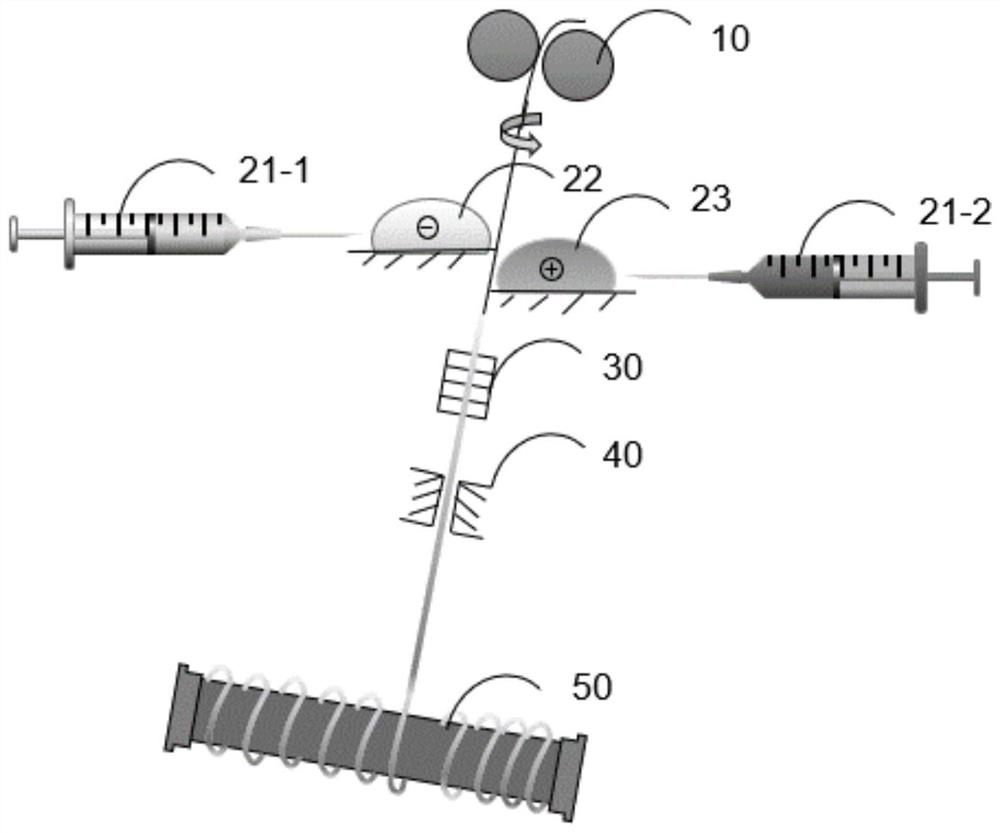

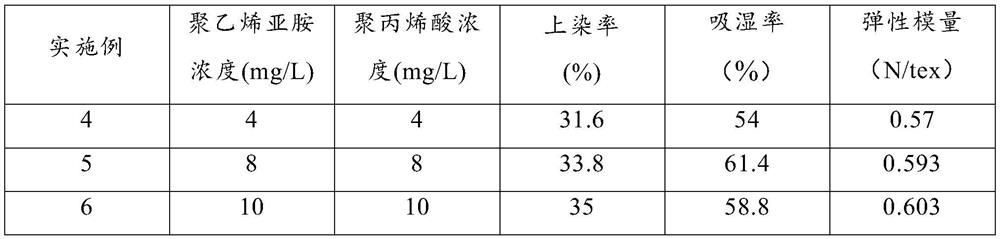

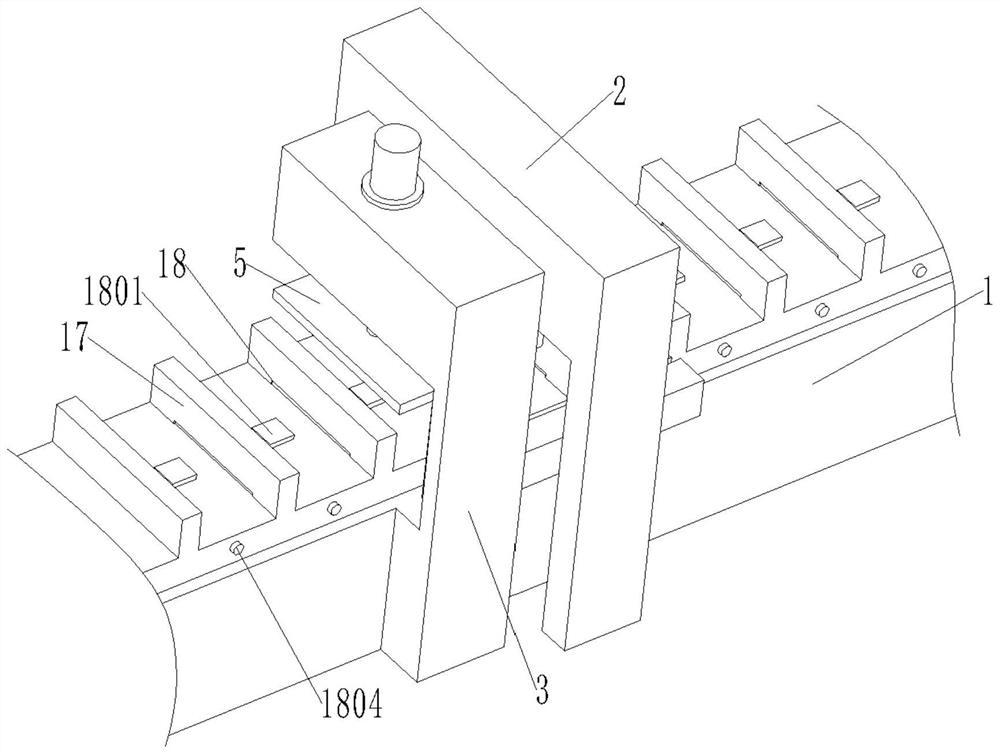

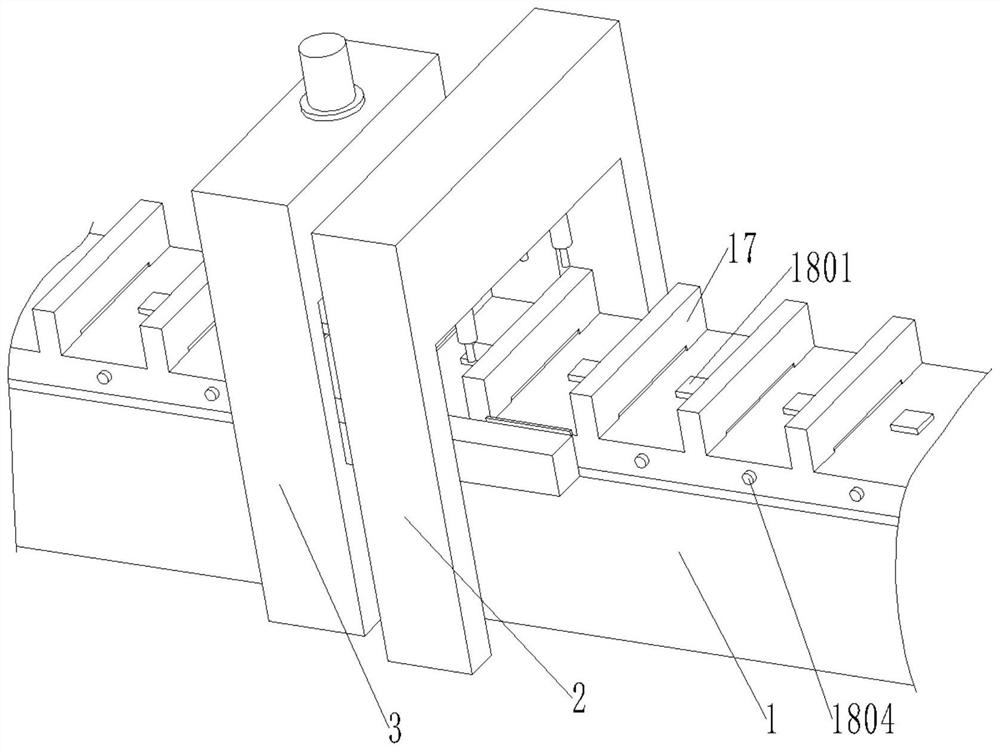

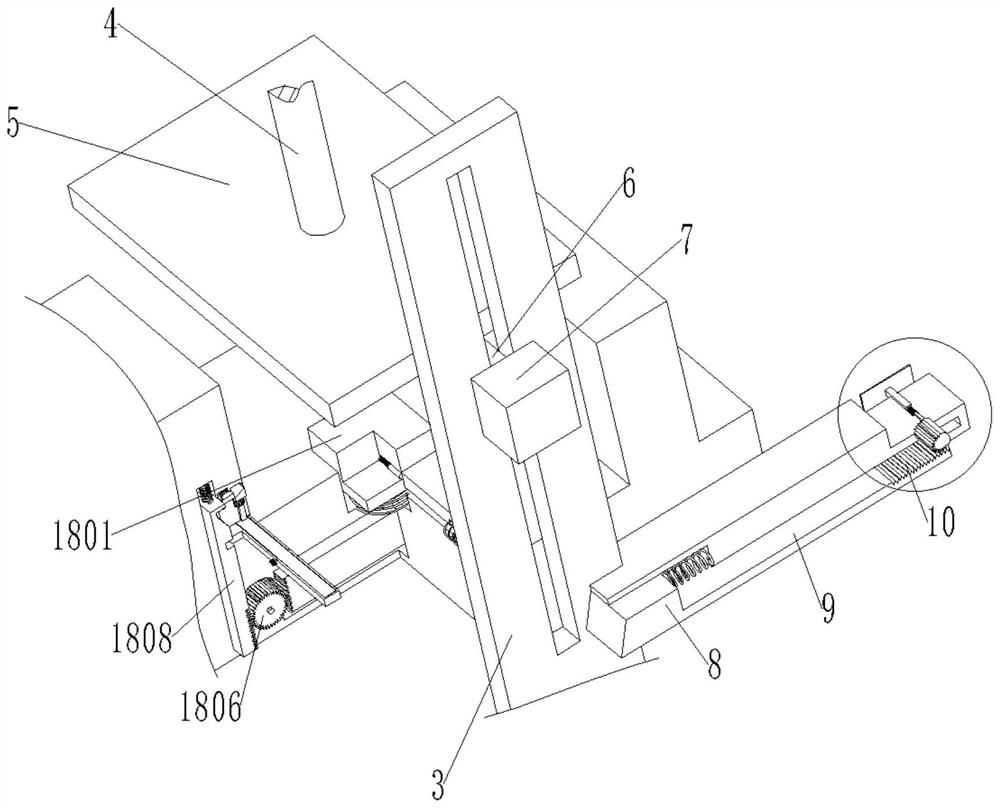

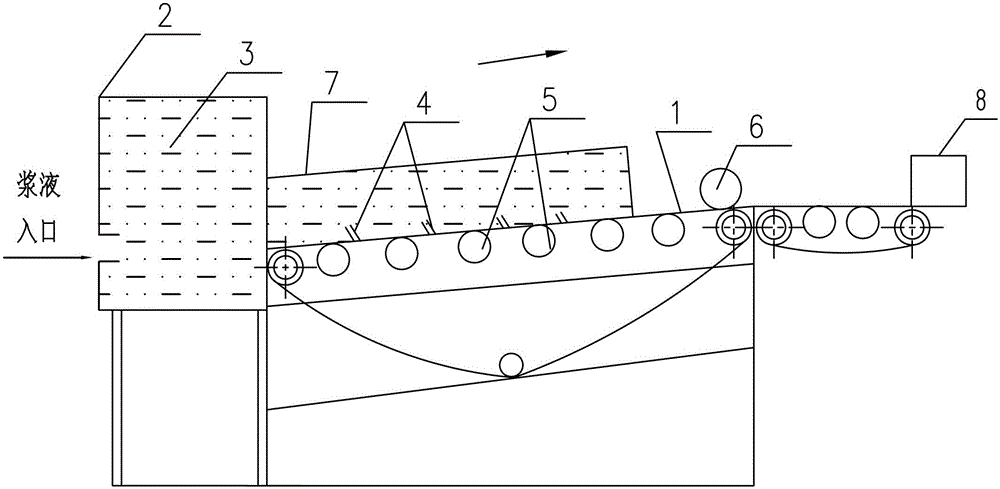

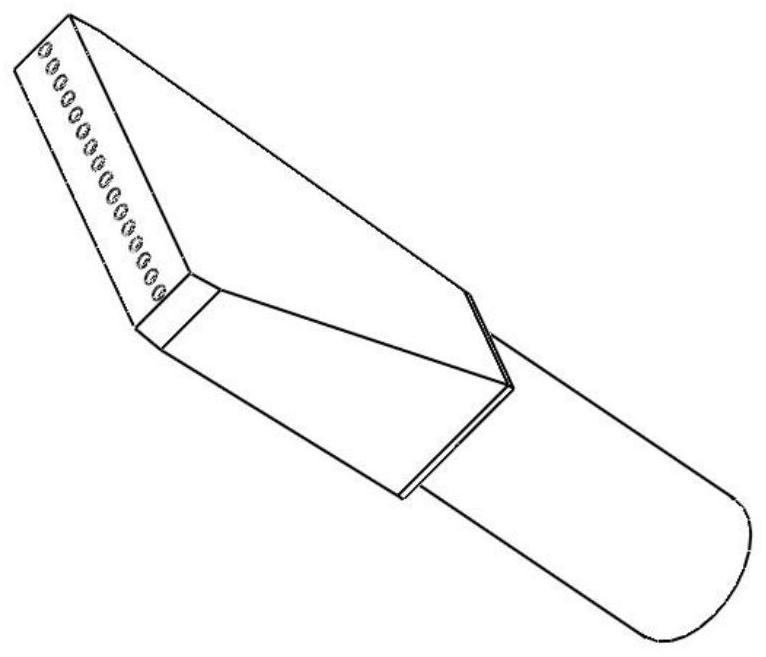

Interface coating modification device and method for functional yarn

ActiveCN113073437ASuitable for continuous large-scale preparationAchieve twistingLiquid/gas/vapor removalYarnYarnFiber

The invention provides an interface coating modification device and method for functional yarn. The coating modification device comprises a yarn feeding module, a yarn rotating module, a modification liquid coating module, a drying module and a winding module. Fibers or the yarn are sequentially fed into the modification liquid coating module, the yarn rotating module and the drying module, so that the fibers or the yarn are in rotating contact with a cationic polyelectrolyte solution and an anionic polyelectrolyte solution in the modification liquid coating module, and then the cationic polyelectrolyte solution and the anionic polyelectrolyte solution are further uniformly adhered to the surfaces of the fibers or the yarn to form a non-water-soluble polyelectrolyte composite membrane; then feeding the membrane to the drying module for drying; and finally, carrying out winding and collecting by the winding module. According to the device and method, the application range of polyelectrolyte is expanded, the problem of flocculation or precipitation caused by contact of the polyelectrolyte due to attraction of positive and negative charges is avoided, and rapid and large-scale production of the high-performance yarn can be realized.

Owner:WUHAN TEXTILE UNIV

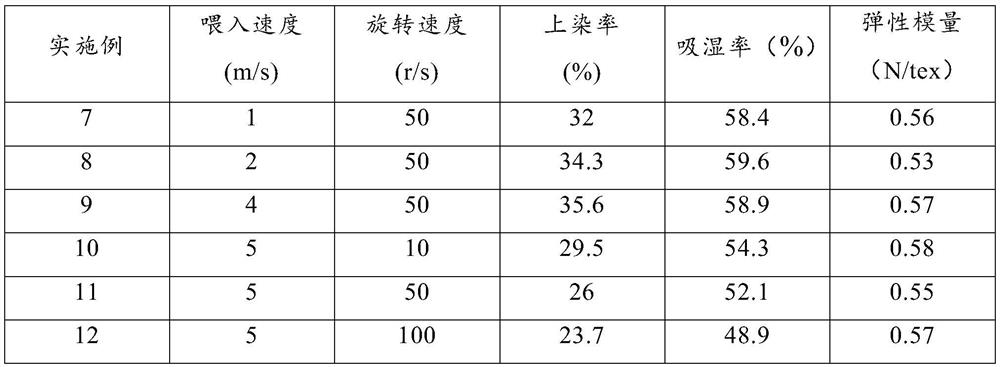

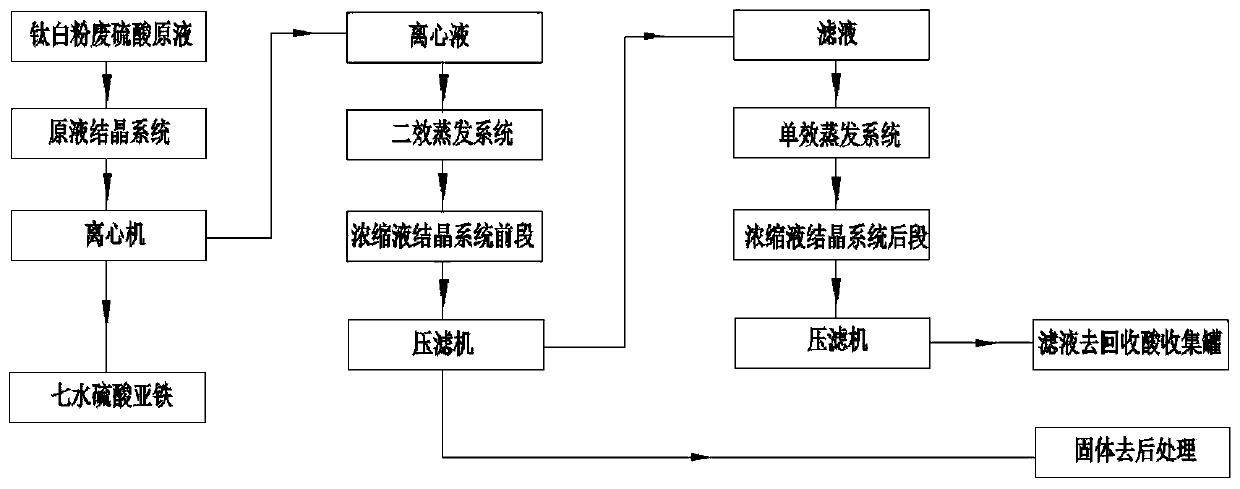

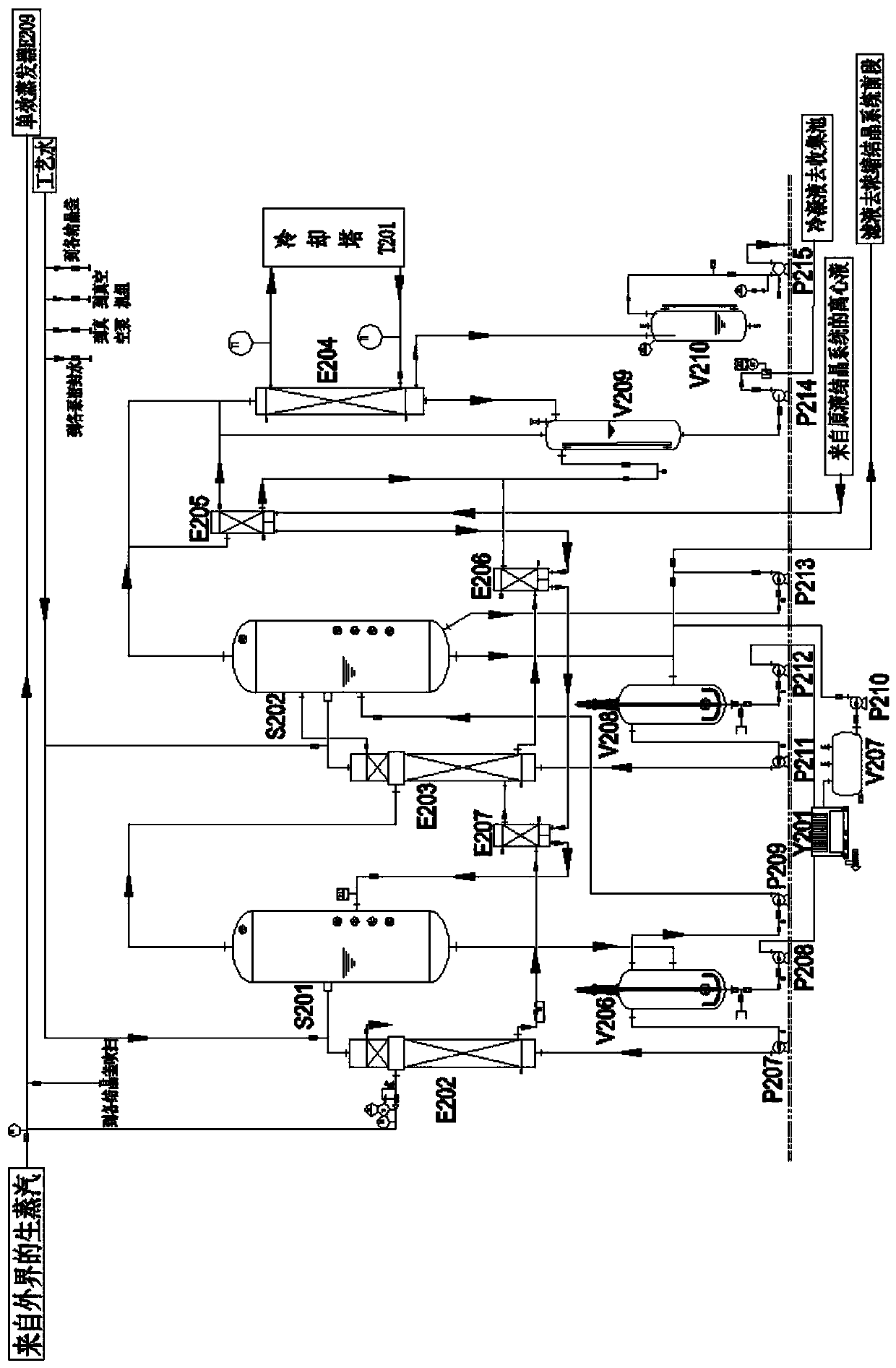

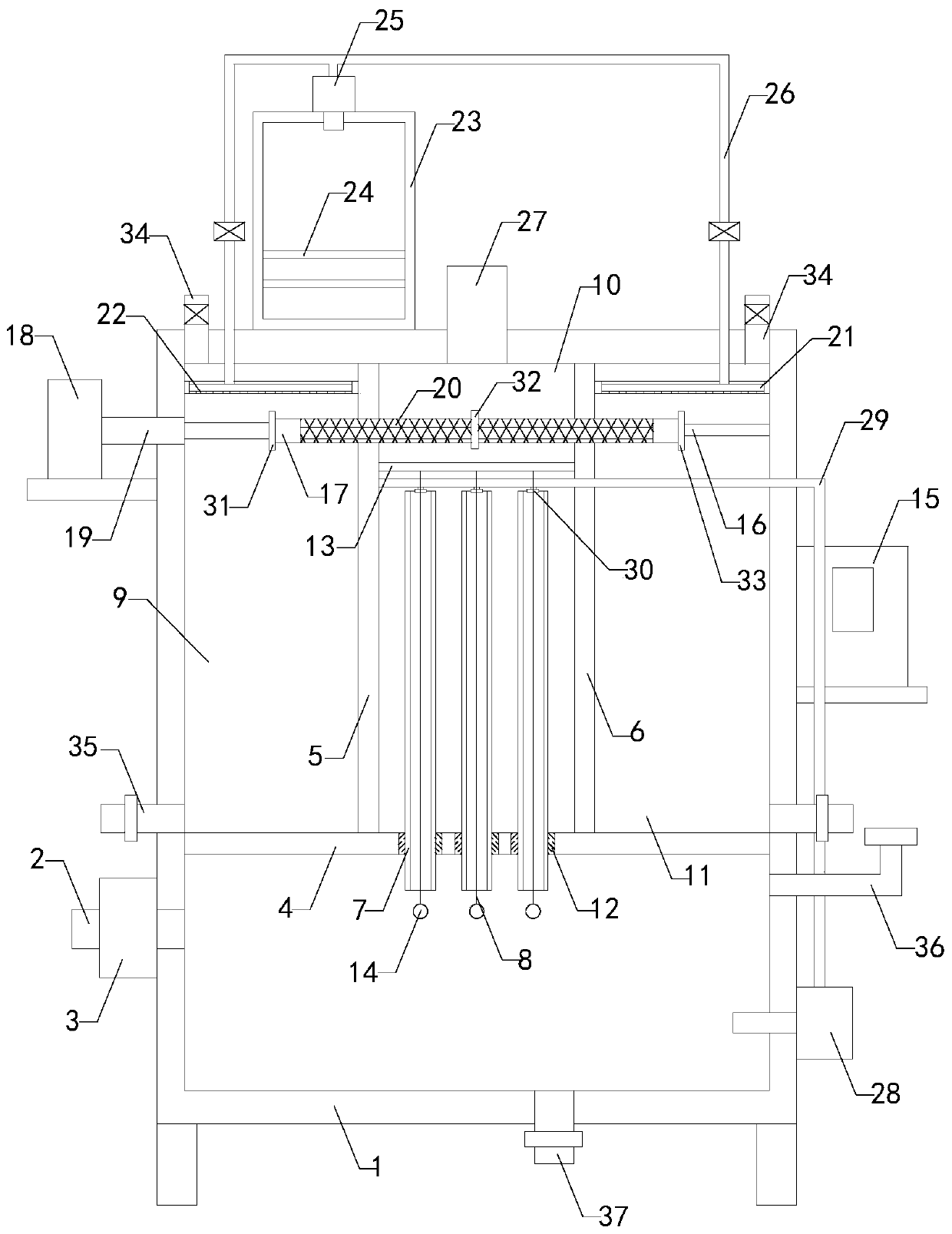

Three-stage negative pressure evaporation crystallization treatment process and device for titanium dioxide waste sulfuric acid

PendingCN111517397AHigh recovery ratePut an end to crystallizationWater/sewage treatment by centrifugal separationTitanium and titanyl sulfatesFerrous sulfate ironPhysical chemistry

The invention discloses a three-stage negative pressure evaporation crystallization treatment process and a device for titanium dioxide waste sulfuric acid. The process comprises the following steps:crystallizing and separating of ferrous sulfate in a titanium dioxide waste sulfuric acid stock solution by using a stock solution crystallization system is carried out, and centrifugally separating are carried out to obtain a ferrous sulfate heptahydrate solid and mother liquor; through the cooperative cooperation of a double-effect evaporation system, a single-effect evaporation system and a concentration and crystallization system, the possibility of crystallization and blockage of materials in the evaporator is eliminated, and the stable operation of the device is ensured; centrifugate from the stock solution crystallization system is evaporated and concentrated in the double-effect evaporation system to improve acidity and then is introduced into a front section of the concentration and crystallization system; cooling, crystallizing and filter pressing are carried out to obtain a large amount of sulfate solids; wherein the mass concentration of sulfuric acid in filtrate reaches 50%, the filtrate is continuously introduced into the single-effect evaporation system for forced circulation, the concentration of waste sulfuric acid is increased to the maximum extent, the concentrated waste sulfuric acid solution is introduced into the rear section of the concentration and crystallization system, cooling crystallization is performed, a large amount of sulfate solids are obtained through filter pressing, and a regenerated sulfuric acid solution with the mass concentration larger than or equal to 70% is obtained.

Owner:江苏泰特联合环保科技有限公司

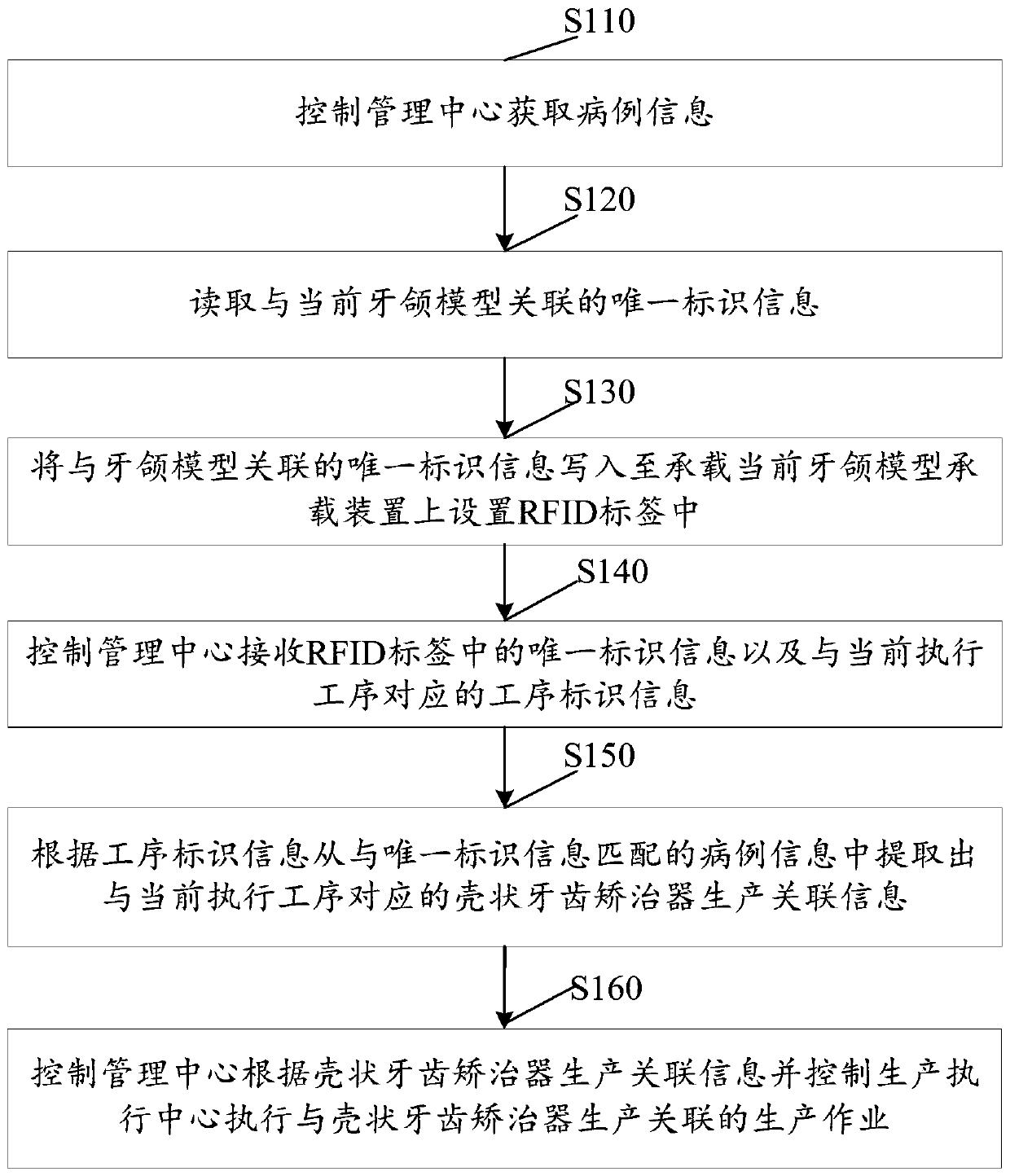

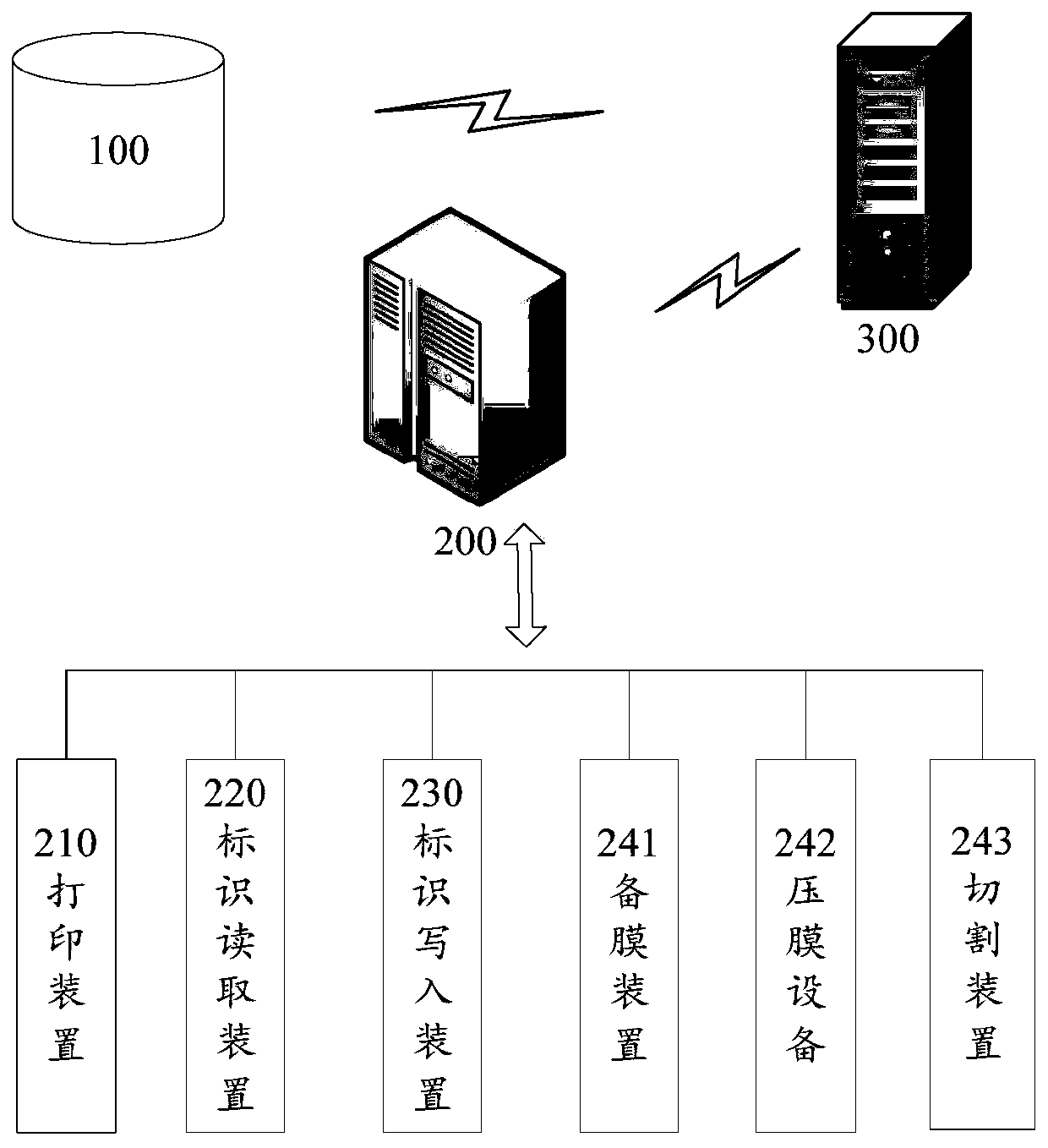

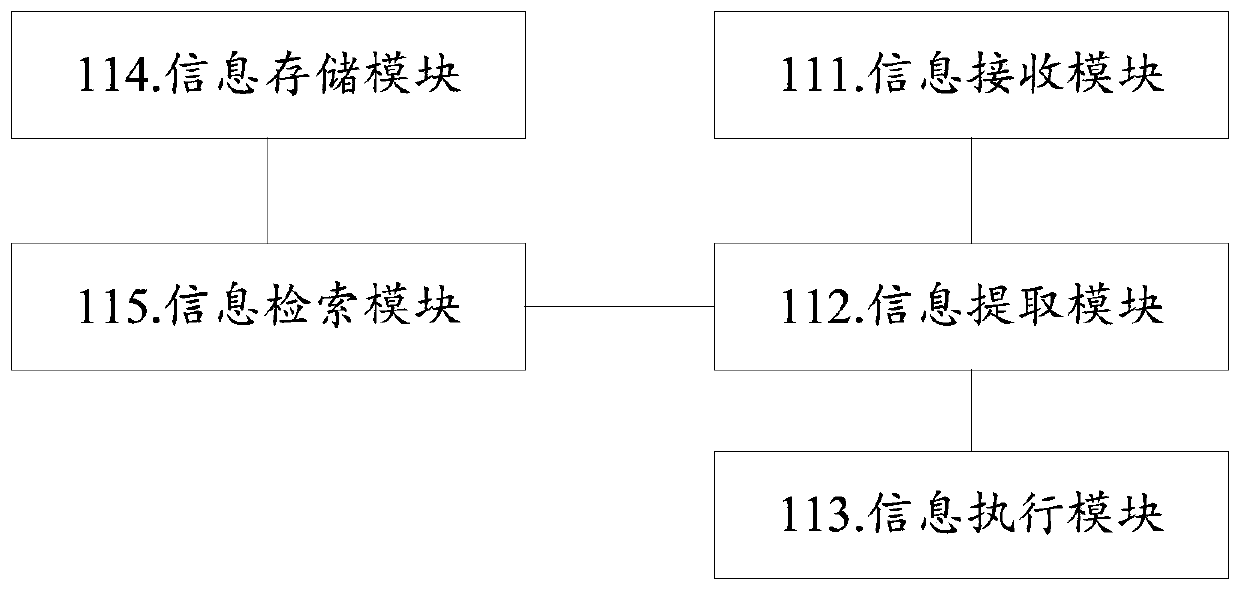

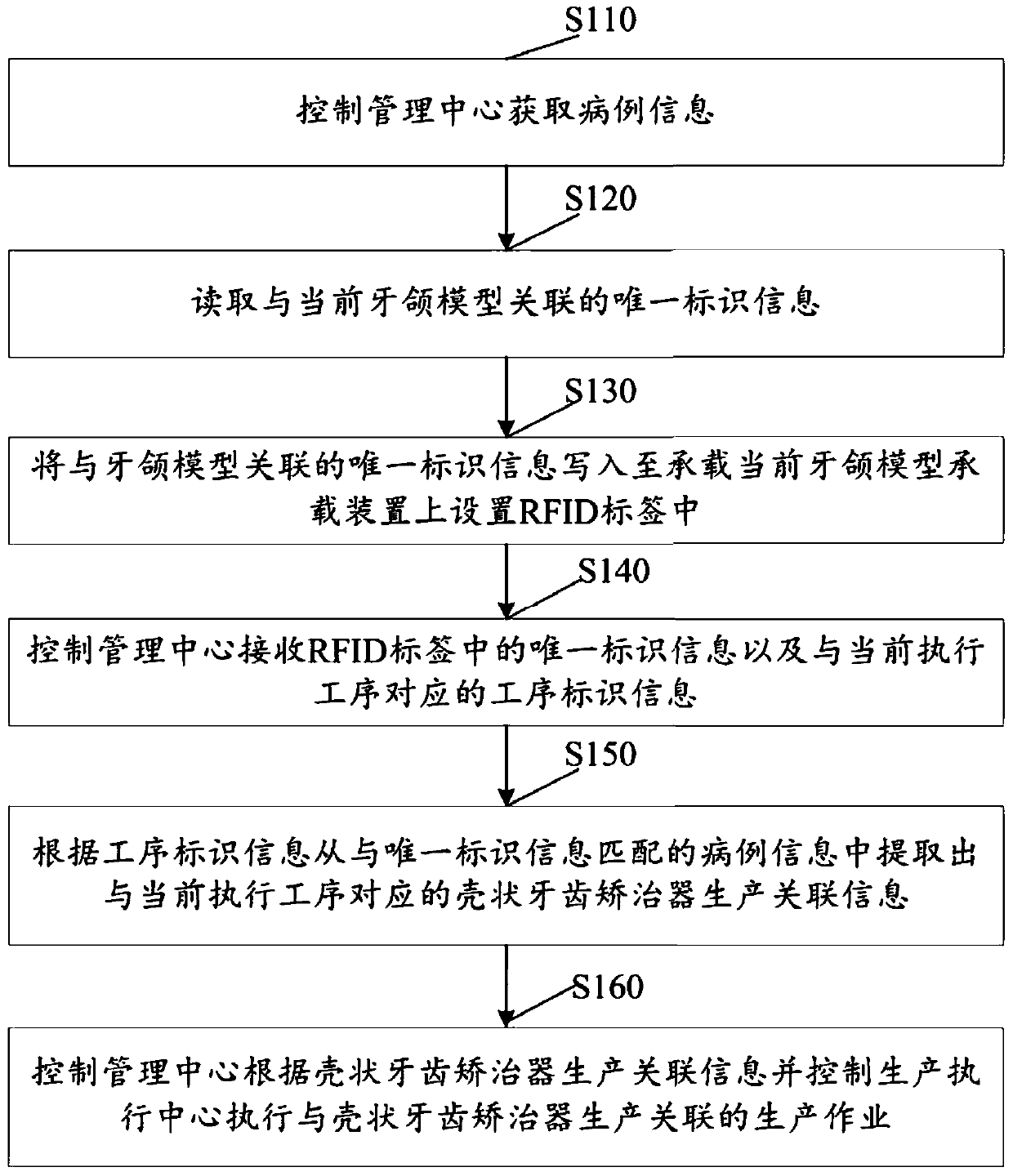

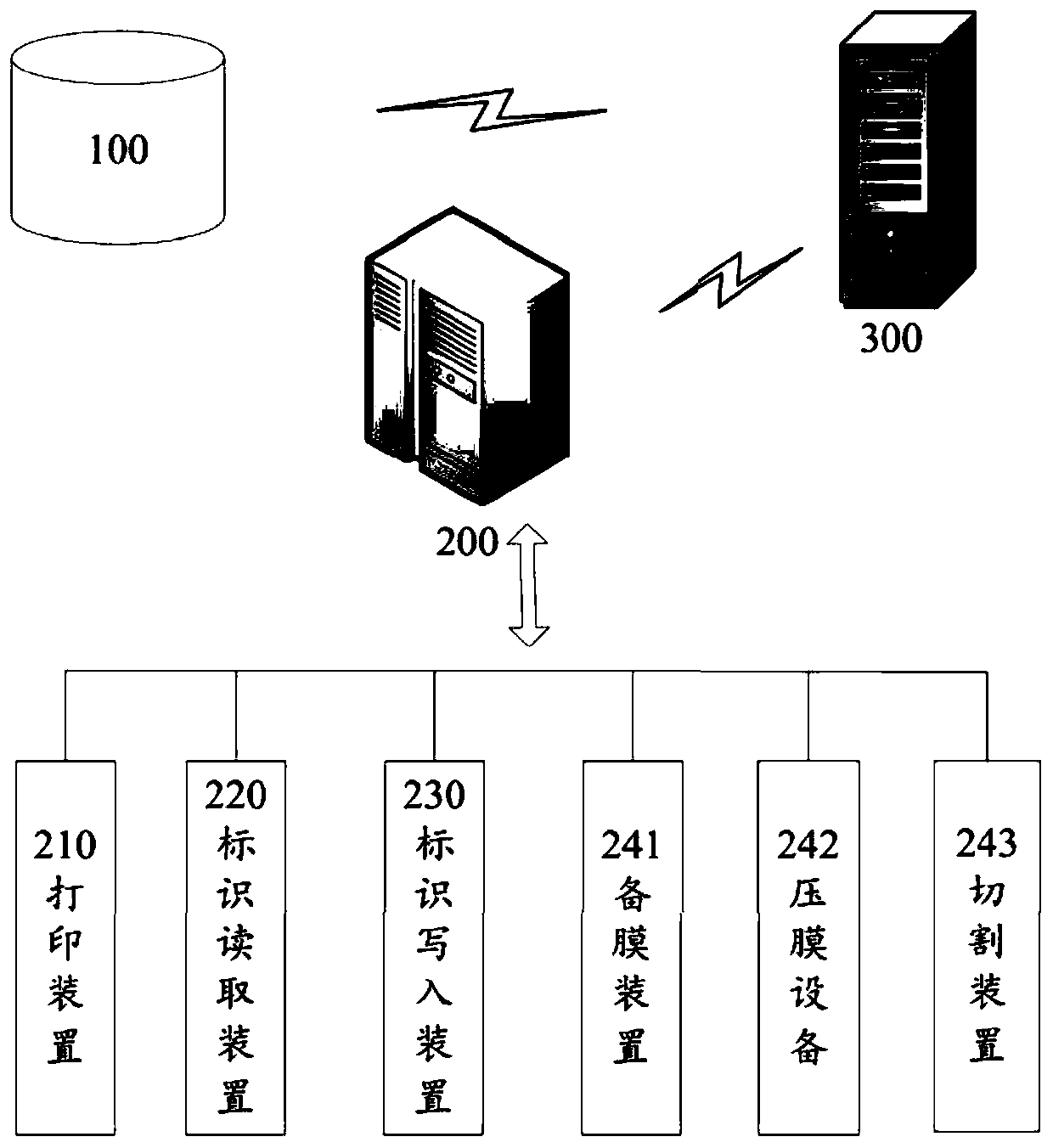

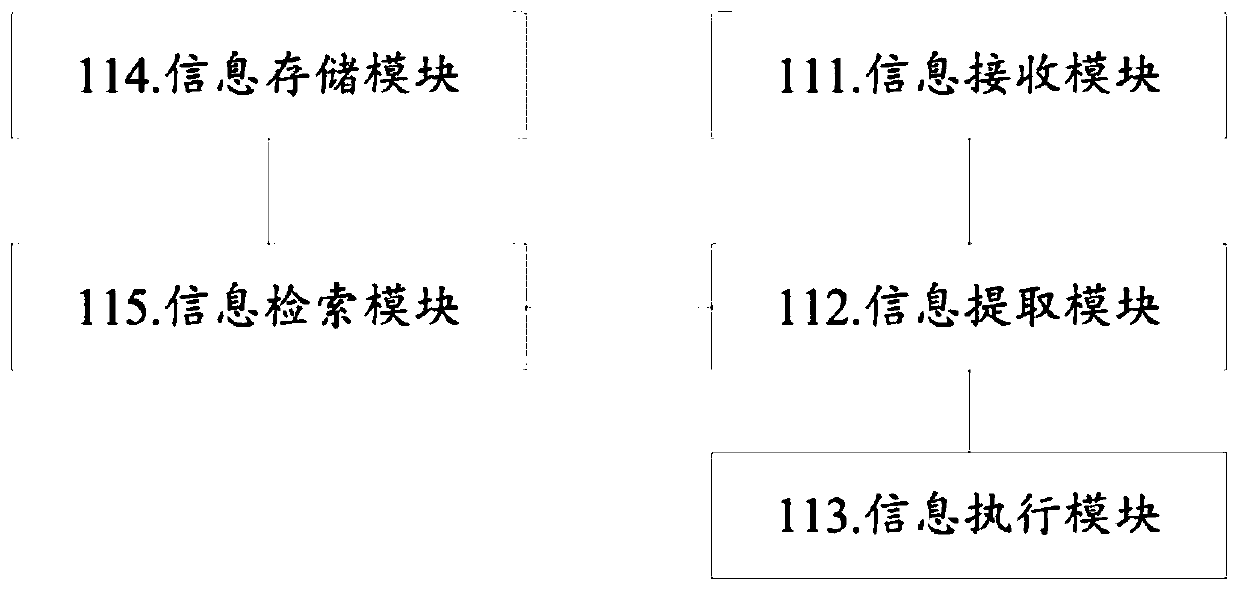

Production method, system and terminal equipment of shell tooth appliance

ActiveCN110664498AIncrease productivityUnrecognizable solutionOthrodonticsTerminal equipmentEmbedded system

The invention discloses a production method, system and terminal equipment of a shell tooth appliance. The production method comprises the following steps: controlling an administration center to acquire clinical case information; reading unique identification information associated with a current dental model through a production execution center; controlling the production execution center to write the unique identification information associated with the current dental model into an RFID tag set on a carrying device which is used for carrying the current dental model; receiving the unique identification information in the RFID tag read by the production execution center and procedure identification information corresponding to a current execution procedure; extracting production associated information corresponding to the current execution procedure from the clinical case information matched with the unique identification information according to the procedure identification information; and transmitting the extracted production associated information corresponding to the current execution procedure to the production execution center, and controlling the production execution center to further control current procedure equipment to execute a production operation associated with production of the shell tooth appliance. The production method has high speed and cannot easily make a mistake by utilizing information interaction.

Owner:浙江正雅齿科股份有限公司

Shell-shaped tooth appliance production method and system and terminal equipment

InactiveCN110522526AIncrease productivityUnrecognizable solutionOthrodonticsProcess equipmentTerminal equipment

The invention discloses a shell-shaped tooth appliance production method and a system and terminal equipment. The shell-shaped tooth appliance production method comprises the following steps: collecting case information by a control management center; reading unique identification information associated with a current dental model through a production execution center; controlling the production execution center, reading the unique identification information associated with the current dental model into a label 5) arranged on a bearing device for bearing the current dental model; receiving unique identification information in the label 5) read by the production execution center and process identification information corresponding to the current execution process; extracting production associated information corresponding to the currently executed process from the case information matched with the unique identification information according to the process identification information; andsending the extracted production associated information corresponding to the current execution process to the production execution center, and controlling the production execution center to further control of the current process equipment to execute the production operation associated with the production of the shell-shaped dental appliance. The information interaction speed is high, and errors are not likely to happen.

Owner:浙江正雅齿科股份有限公司

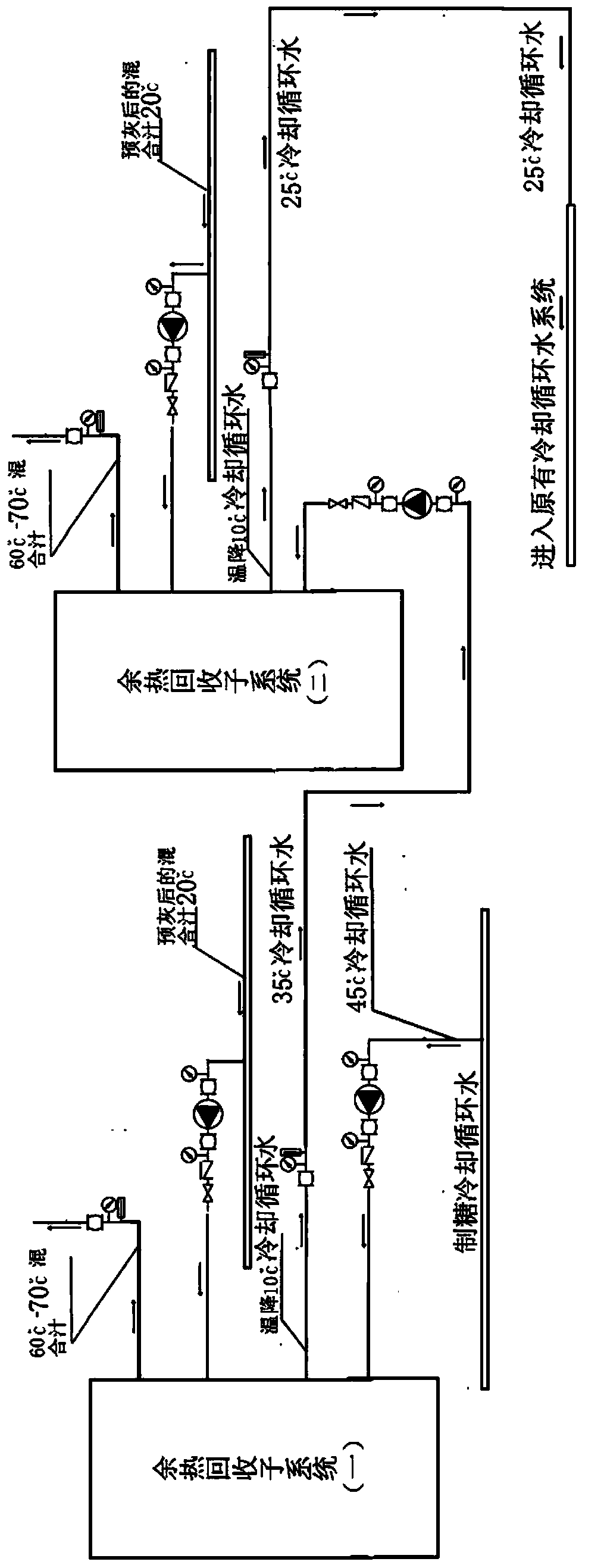

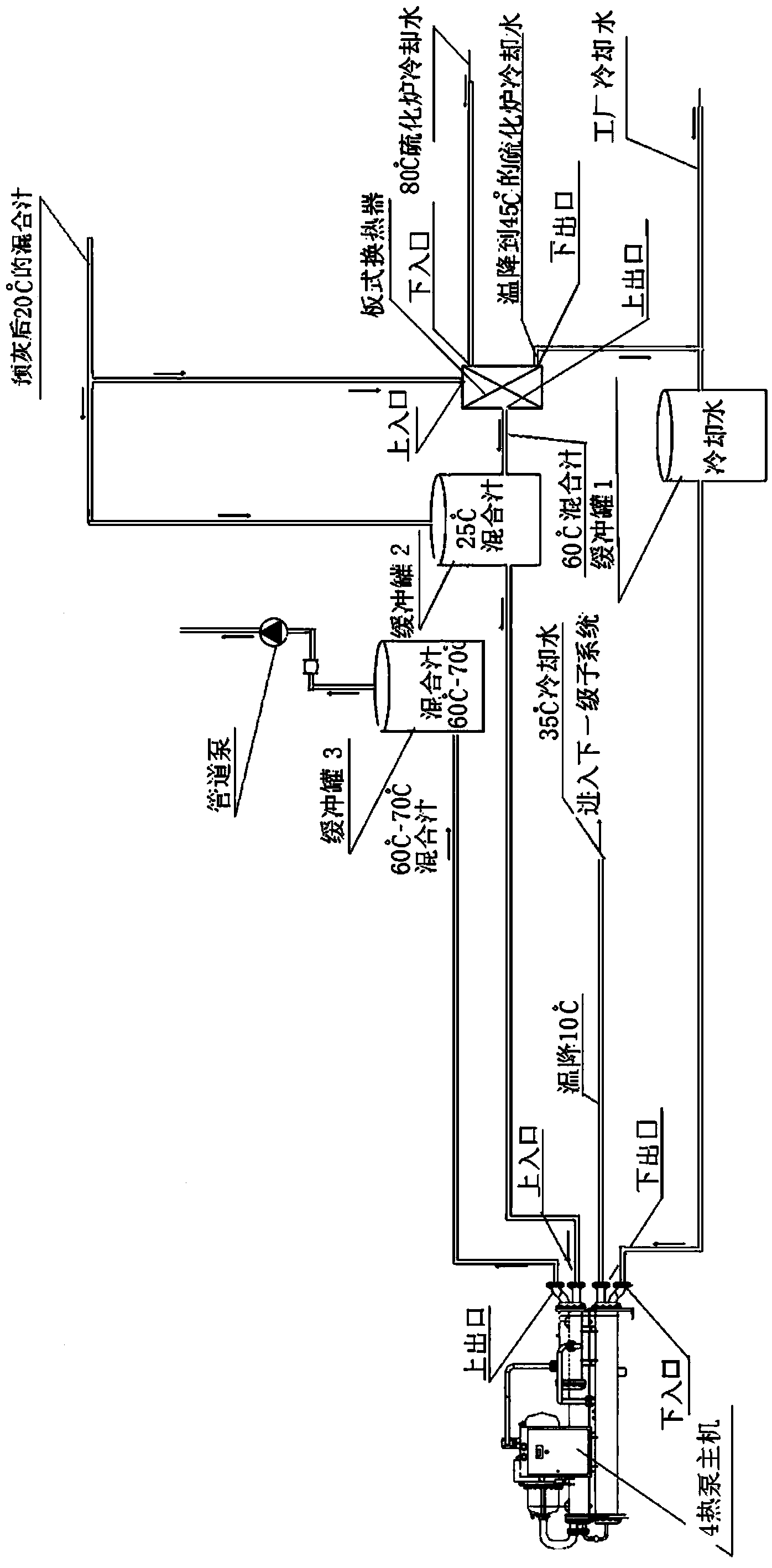

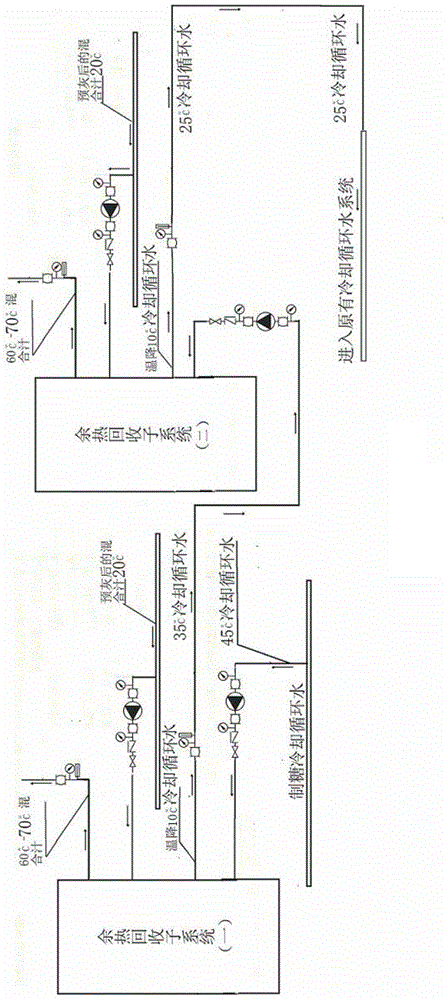

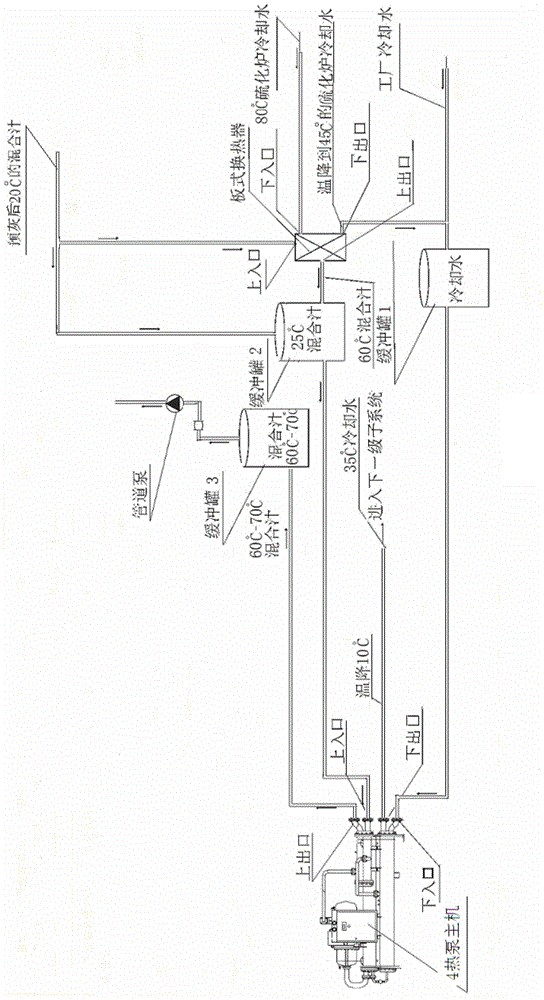

Low temperature exhaust heat recovery process of circulation cooling water of sugar refinery

InactiveCN103898242AReduce the temperatureSave energySugar juice boiling/evaporationThermal energyPlate heat exchanger

The invention discloses a low temperature exhaust heat recovery process of circulation cooling water of a sugar refinery. The process mainly consists of a plate heat exchanger, a buffer tank, a circulating tank, a pipeline pump, a circulating pump and a heat pump main machine. According to low temperature circulation cooling water (averagely at 45 DEG C) generated in the sugar making production process, low grade cooling water which cannot be utilized in the sugar making production process of the sugar refinery is extracted through the process and is converted into high grade utilizable heat energy (adjustable in temperature in a range of 55-60 DEG C) for re-production (for example, heating of pre-limed mixed juice or other energy consuming processes). The process disclosed by the invention not only can recover the low temperature exhaust heat of the cooling water, but also can provide the cooling water (adjustable in temperature in a range of 5-30 DEG C). For the sugar making enterprise, not only is the unit energy consumption for making sugar reduced, but also high quality low temperature cooling water is provided, and thus the yield of sugar and the quality of sugar are greatly improved.

Owner:翟东 +1

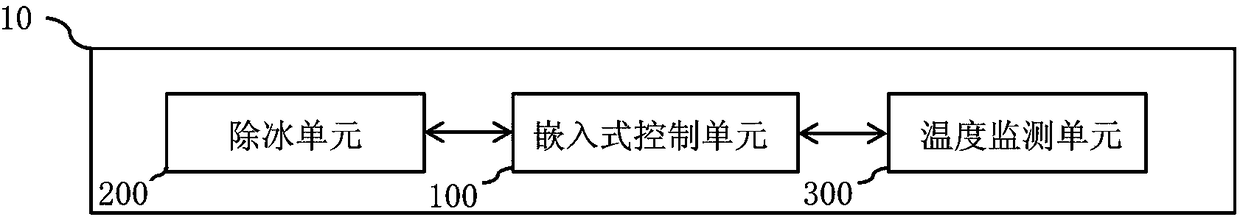

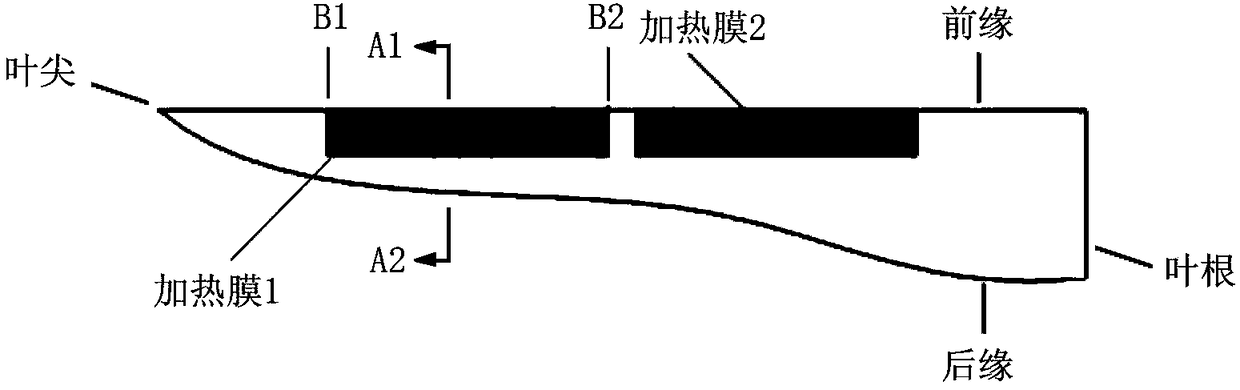

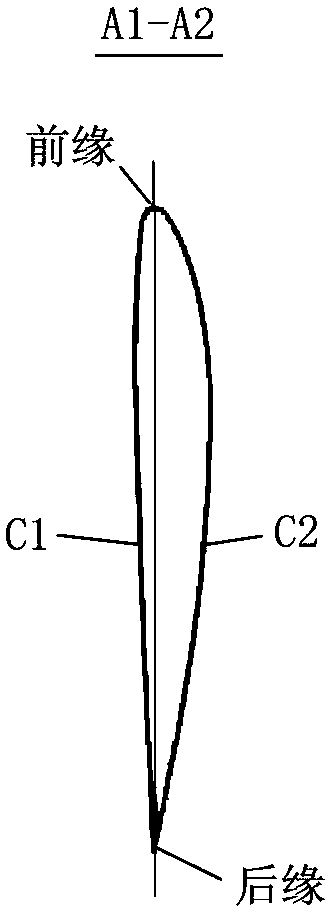

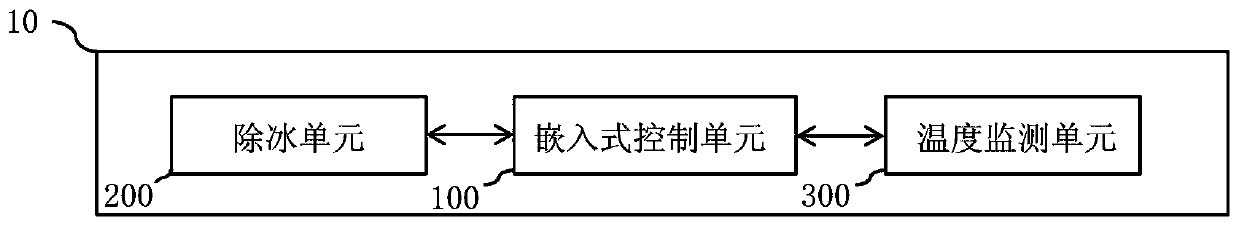

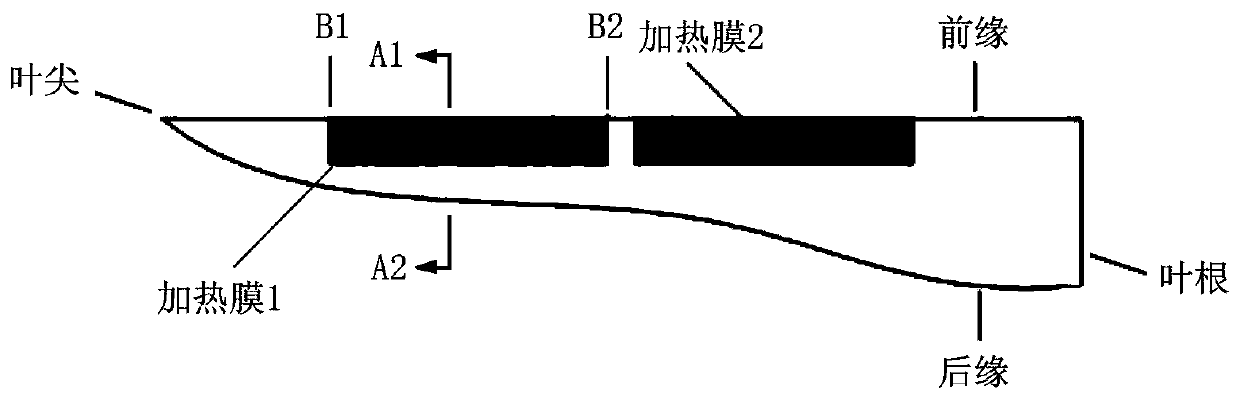

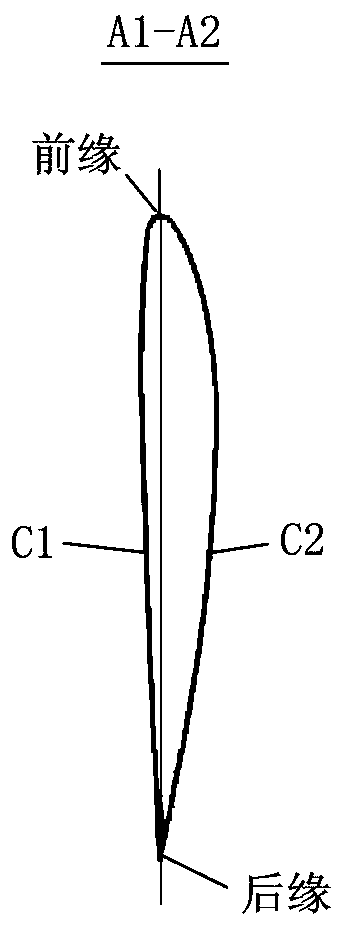

Blade ice removing equipment and blade ice removing method applied to wind generating set

ActiveCN108252878AWill not affect the production processFlexible configurationMachines/enginesWind energy generationEngineeringWind power generation

The invention relates to blade ice removing equipment and a blade ice removing method applied to a wind generating set. The blade ice removing equipment comprises an ice removing unit, a temperature detecting unit and an embedded type control unit, wherein the ice removing unit is used for removing ice from each blade; the temperature detecting unit is used for detecting the temperature of each blade; and the embedded type control unit is used for determining whether to control the ice removing unit to implement ice removal operation or not according to a received freezing signal from an external device and determining whether to control the ice removing unit to stop the ice removal operation or not according to a detected temperature value detected by the temperature detecting unit.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

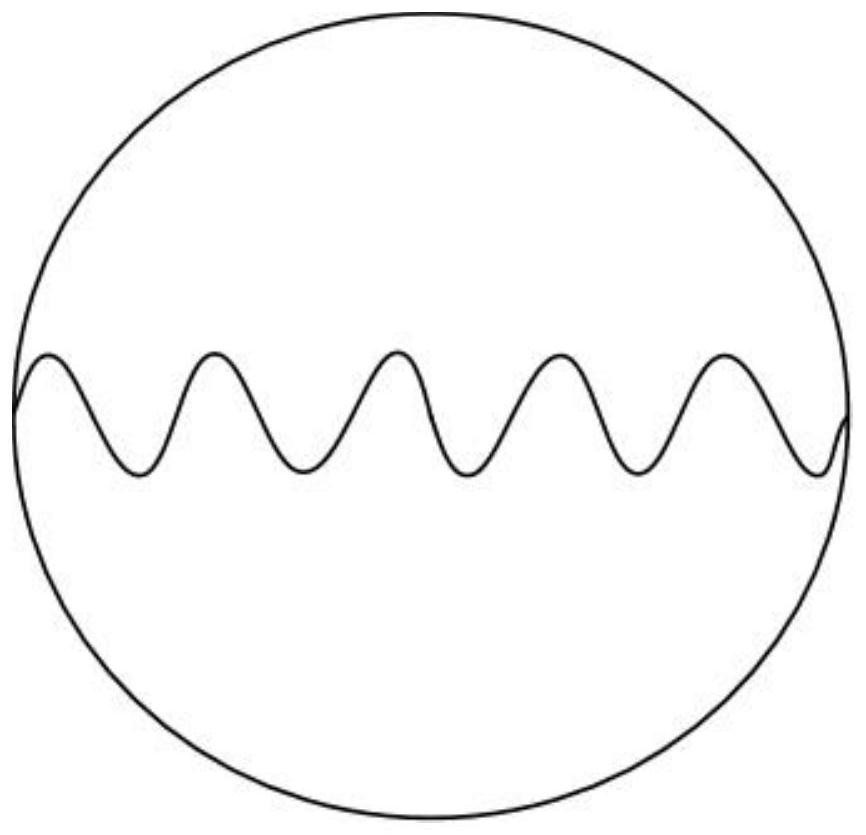

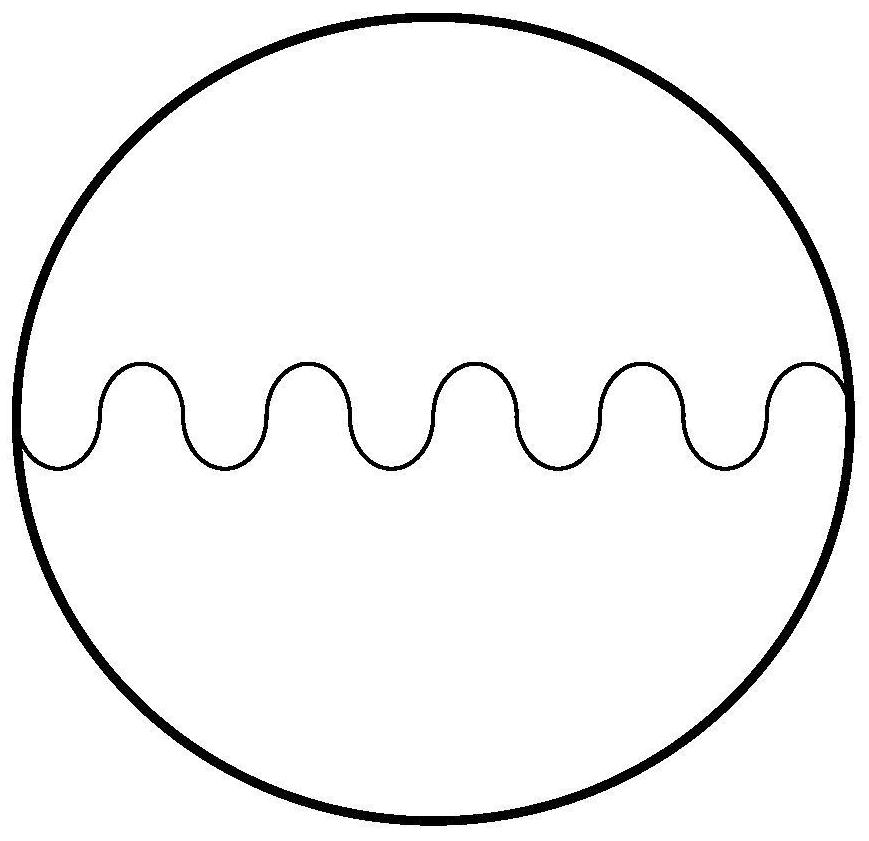

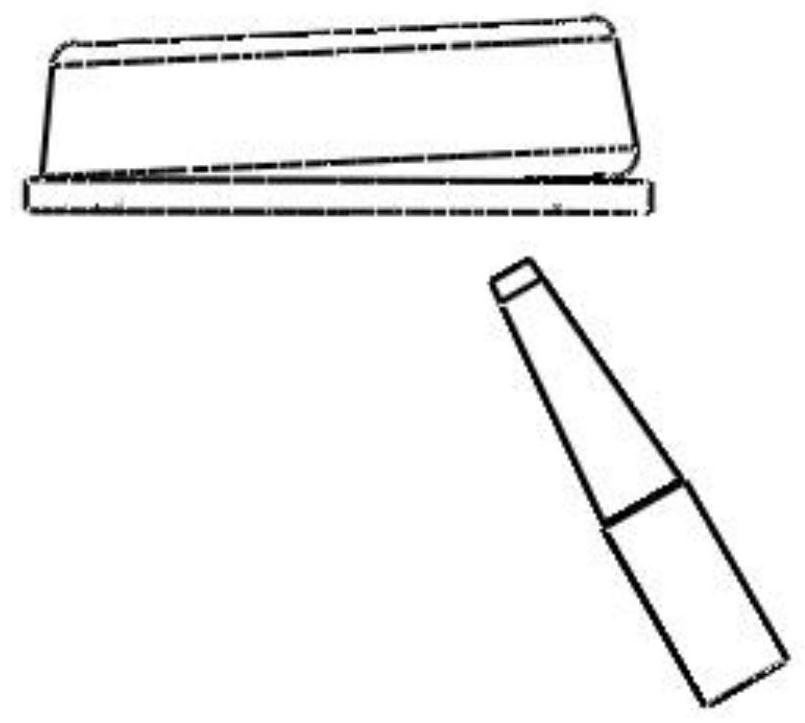

Multi-layer composite thin plate and manufacturing method thereof

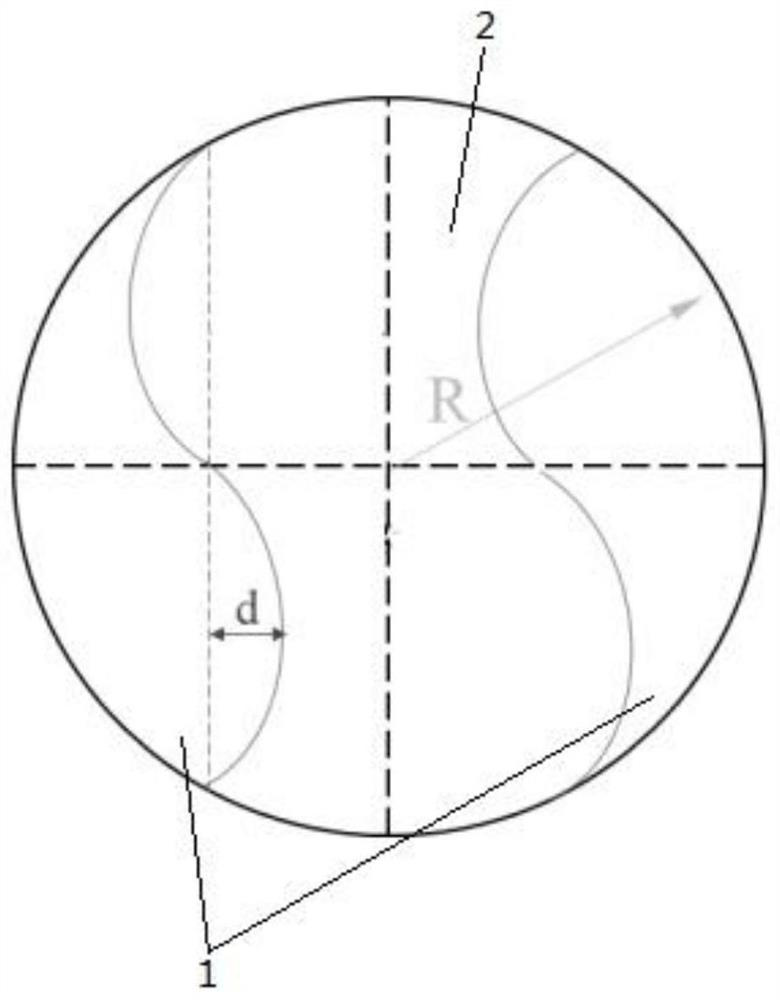

ActiveCN113857252AIncrease the effective contact areaEasy to spreadAuxillary arrangementsMetal rolling arrangementsThin slabComposite plate

The invention relates to the technical field of composite materials, in particular to a manufacturing method of a multi-layer composite thin plate. The manufacturing method of the multi-layer composite thin plate comprises the following steps that aluminum alloy and magnesium alloy materials are machined to be in the needed shape and size, obtained three layers of plate-shaped alloy can be combined to form a cylinder, the magnesium alloy in the cylinder is located between the two layers of aluminum alloy, and the attached surfaces of the two layers of aluminum alloy and the magnesium alloy are S-shaped arc surfaces; the prepared aluminum alloy and magnesium alloy materials are polished and then cleaned, and the cleaned alloy materials are assembled and combined so that the materials can be fixed to form the cylinder; an assembled blank is preheated, then extrusion forming is conducted, and magnesium-aluminum composite plates are obtained; the composite plates are sawn; the sawn plates are preheated, the preheated composite plates are stacked up and down, then multi-pass and multi-direction hot rolling is conducted, and the aluminum / magnesium / aluminum composite thin plate is obtained; and the rolled composite thin plate is subjected to hot-pressing flattening and then is cooled.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

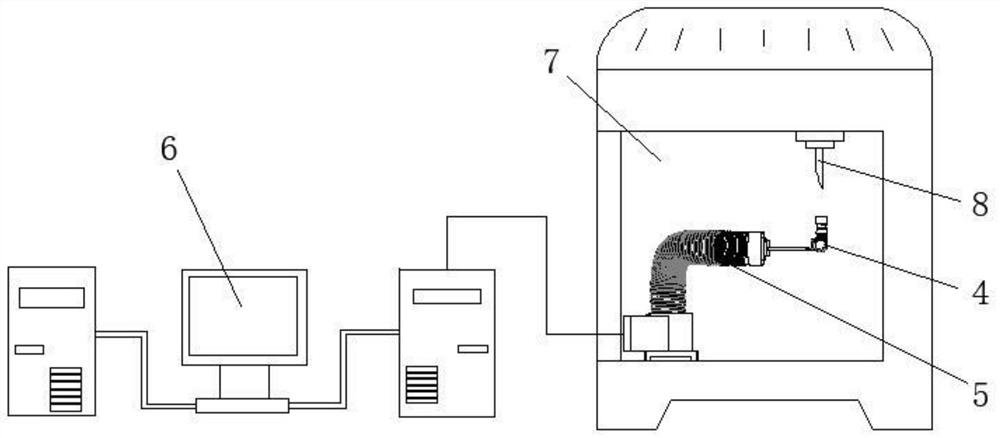

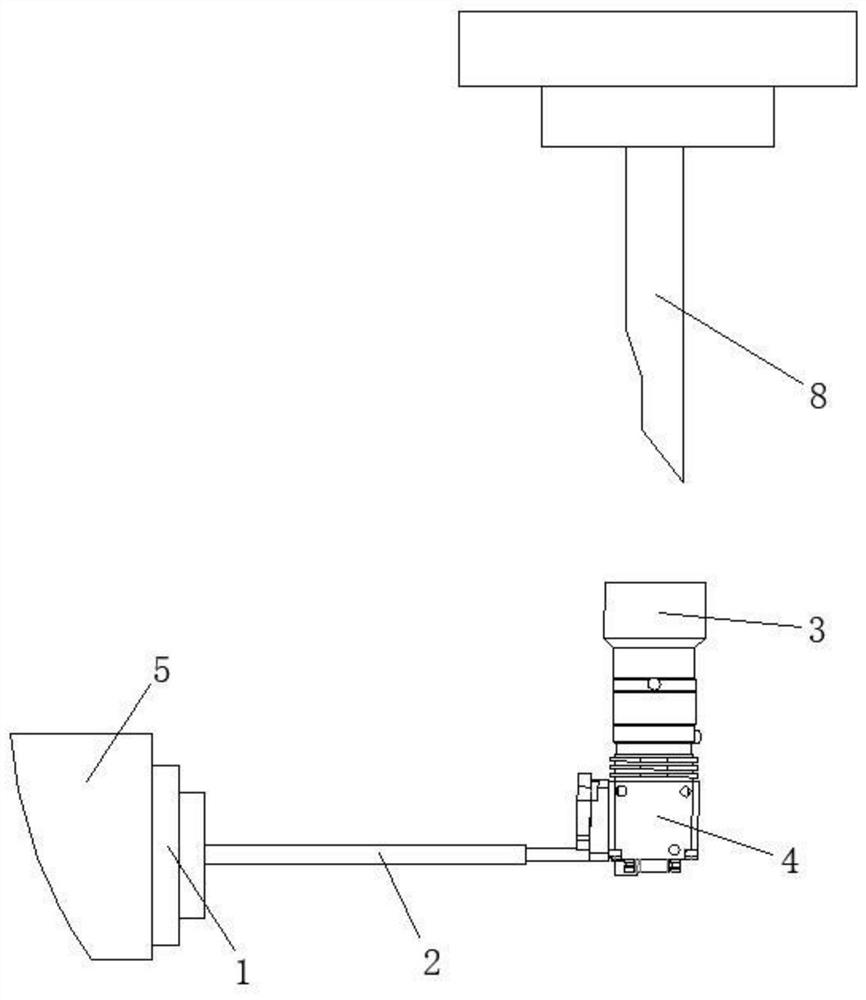

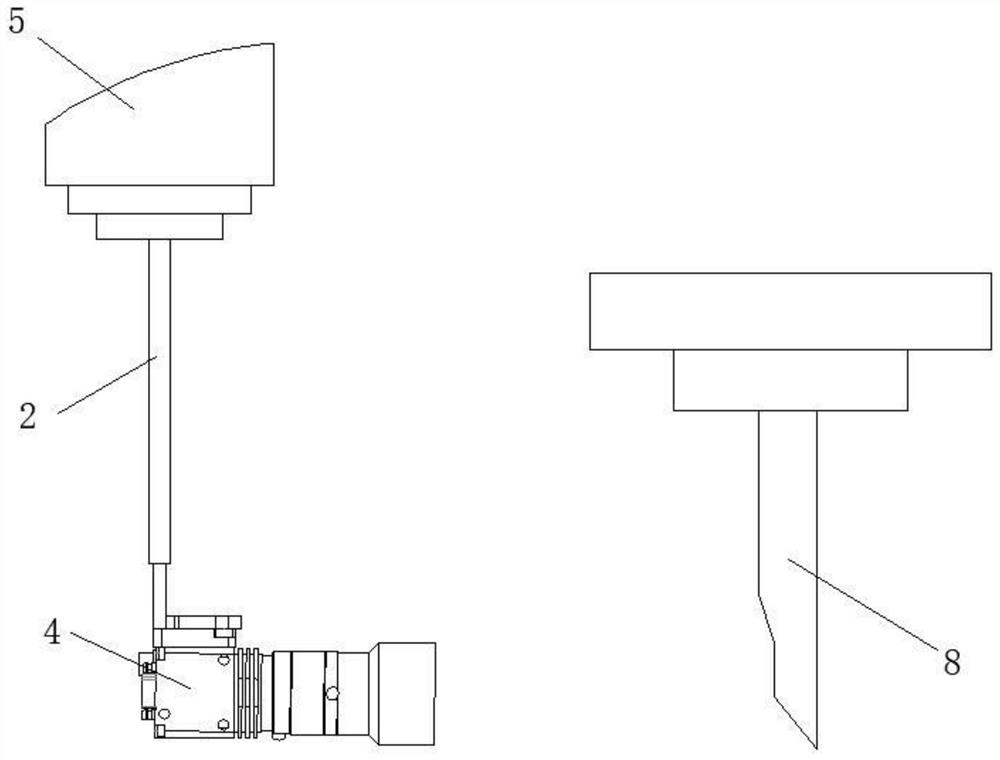

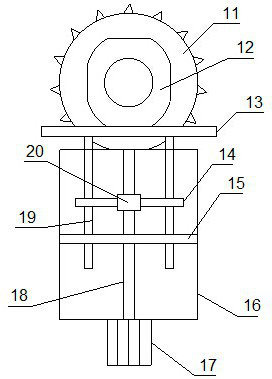

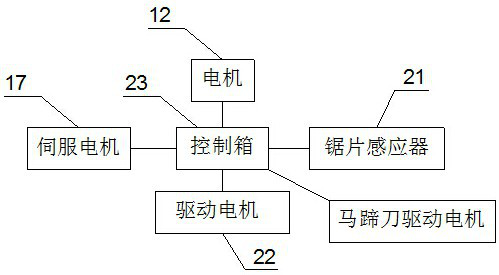

Real-time cutter detection device for machining center and detection method thereof

PendingCN113427321ATo achieve the purpose of detectionWill not affect the production processMeasurement/indication equipmentsImaging processingEngineering

The invention discloses a real-time cutter detection device for a machining center, which comprises an acquisition area, an in-situ detection module is arranged in the acquisition area, the in-situ detection module comprises a soft mechanical arm, and a visual image acquisition system is arranged at the end part of the soft mechanical arm; the detection device further comprises an image processing module; and the image processing module comprises a damage evaluation unit, and the damage evaluation unit is suitable for comparing and evaluating image information with preset information. In addition, the invention further discloses a detection method of the detection device. According to the scheme, through the arrangement of the visual image acquisition system on the soft mechanical arm, cutter images can be acquired through the visual image acquisition system, then the damage evaluation unit judges the abrasion grade of a cutter, and whether the cutter needs to be replaced or not is determined according to whether the damage amount of the cutter reaches a set value or not, so that the purpose of detecting the cutter is achieved, the cutter does not need to be taken down during use, the detection efficiency is high, the production process is not affected, and the practicability is high.

Owner:NANJING UNIV OF SCI & TECH

Ammonia recovery method for gas mixture in hydrogen cyanide production

ActiveCN101264901BAvoid lossReduce manufacturing costHydrogen cyanide preparation/purification/separationAmmonia preparation/separationRecovery methodDesorption

The invention discloses an ammonia recovery method from the mixing gas produced in the process of hydrogen cyanide production, comprising ammonia absorption process, decyanation process, desorption process and rectifying process for solving the technical problem. The invention is characterized in that decyanation process is set separately to recovery hydrogen cyanide gas, avoiding the loss of hydrogen cyanide caused by a large amount of acid gas like hydrocyanic acid contained in the ammonium phosphate solution directly steamed in Versum method, reducing production cost of hydrogen cyanide, reducing the emission of the harmful acid gas like hydrogen cyanide, and avoiding the serious pollution of peripheral enviroment. Besides, the ammonium phosphate solution contains a much smaller amout of hydrocyanic acid after hydrogen cyanide is recovered, which can not influence production process and make the production process more safety.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

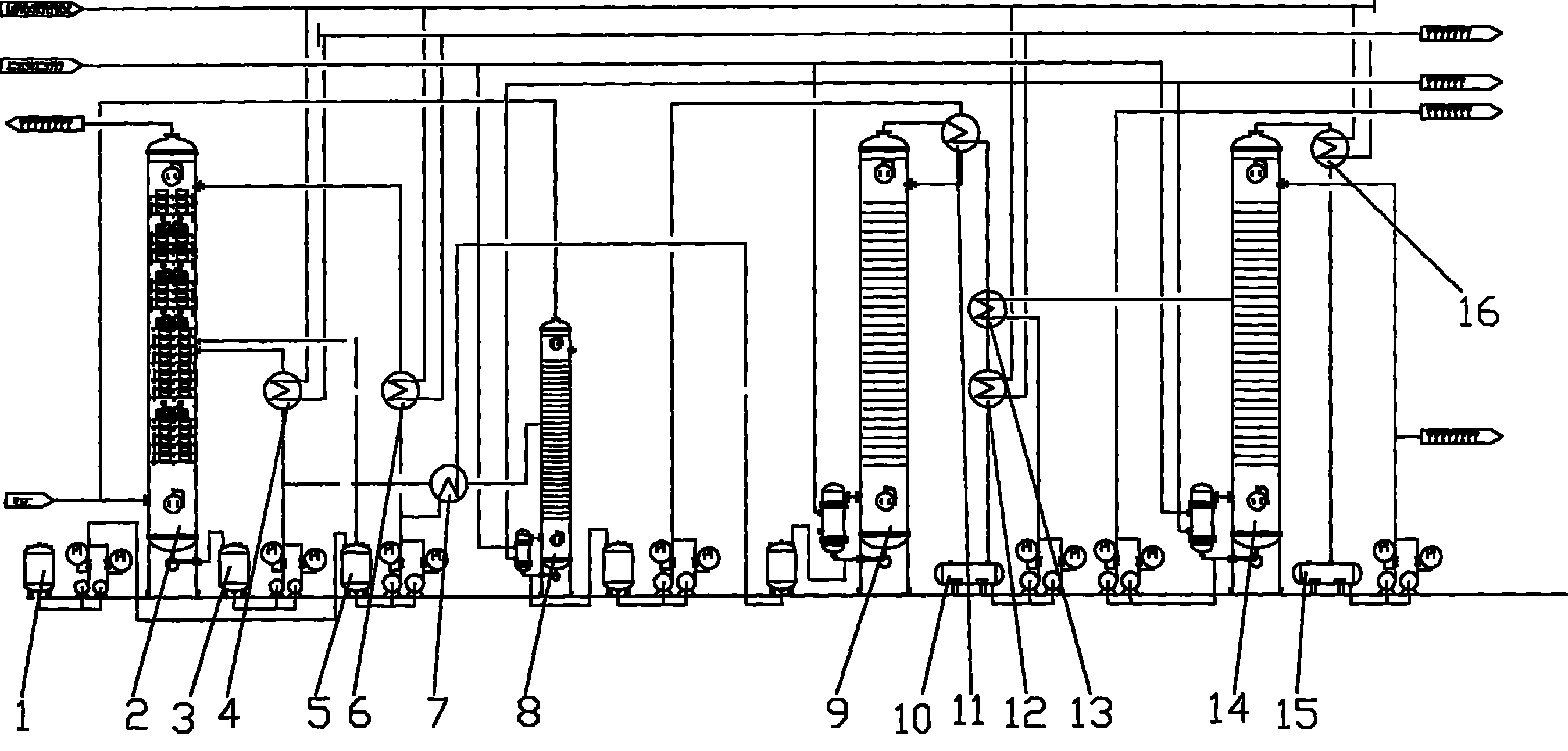

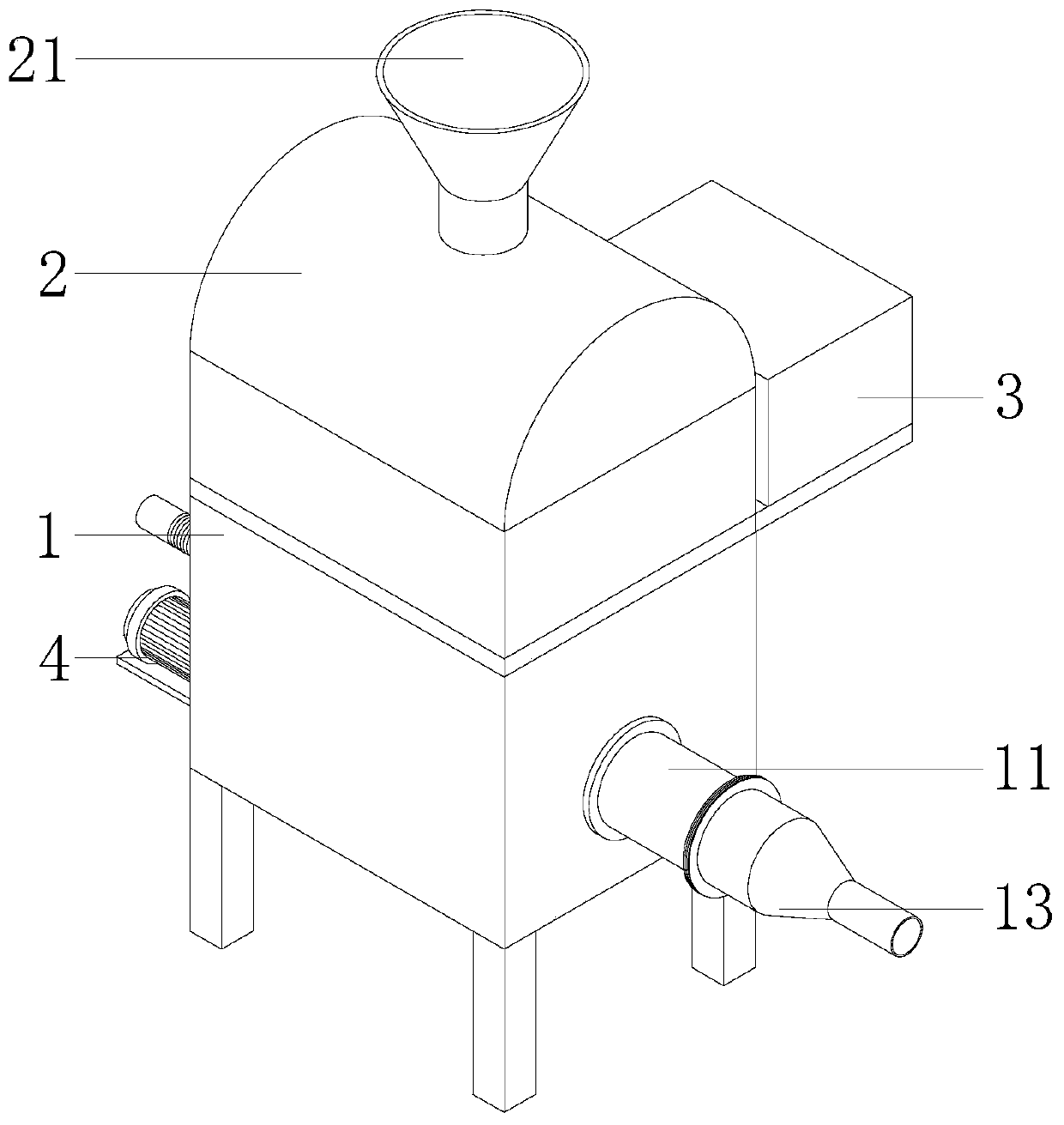

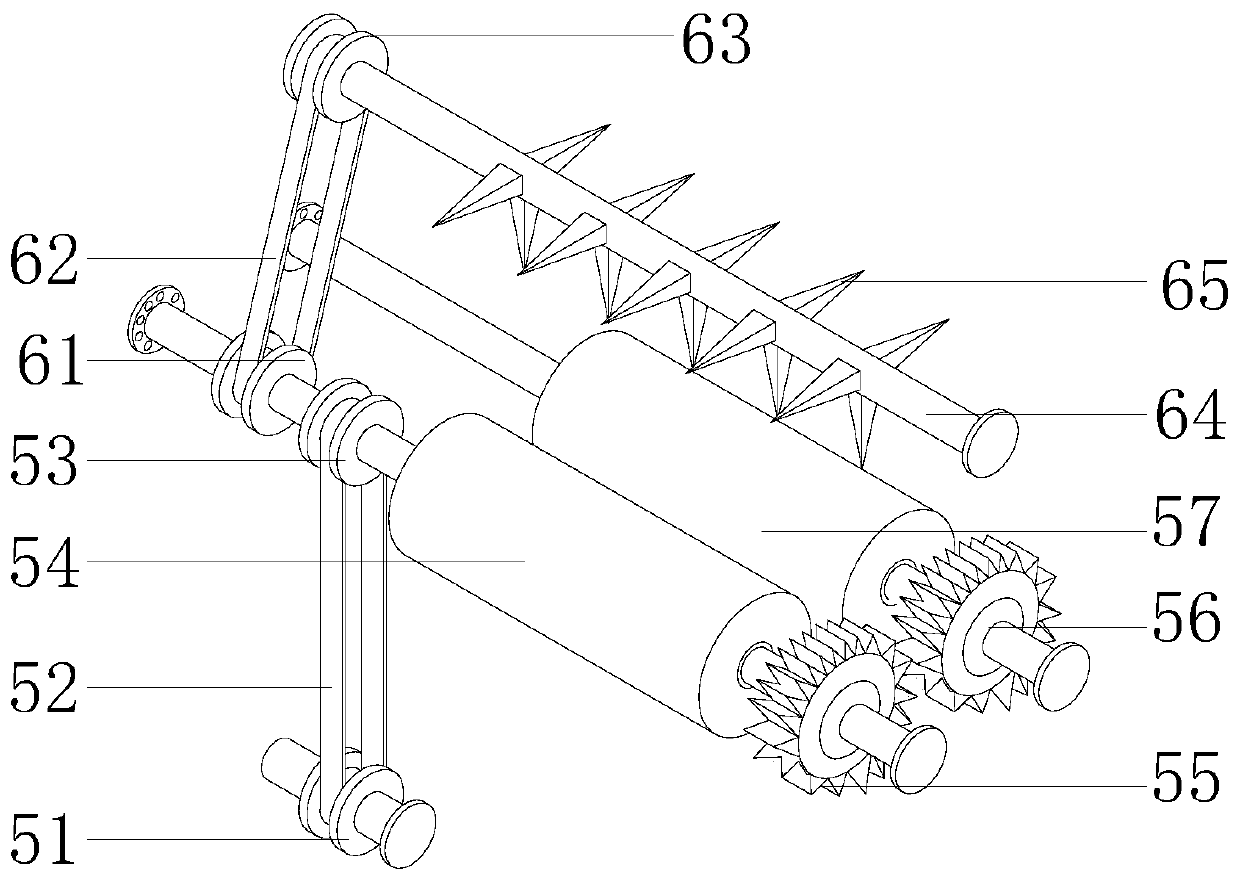

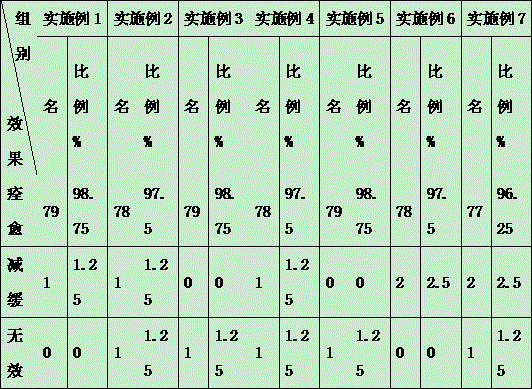

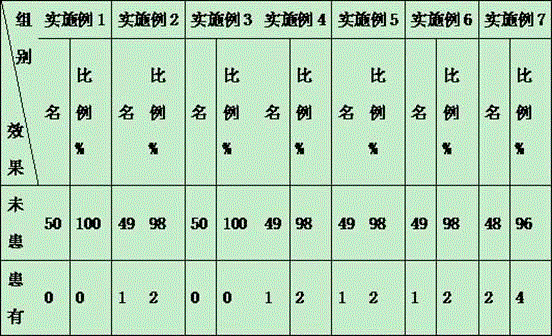

Efficient sausage filling machine for sausage processing

InactiveCN110720497AWill not affect the production processIncrease productivitySausage filling/stuffing machinesMeat processing devicesDrive wheelCrank

The invention provides an efficient sausage filling machine for sausage processing. The efficient sausage filling machine includes a sausage filling box, a sausage filling unit is arranged at one sideof the sausage filling box and includes a drive motor, the drive motor is fixed to one side of the sausage filling box through a bolt and is arranged horizontally, an output end of the drive motor penetrates through a shell of the sausage filling box, extends to the interior of the sausage filling box and is connected with a first drive wheel and a spiral propeller in sequence, a first belt is connected to the top of the first drive wheel, and a first driven wheel is rotatably connected to the end, away from the first drive wheel, of the first belt; a first rotation shaft is in through connection with the center of one side of the first driven wheel, and the end, close to the drive motor, of the first rotation shaft penetrates through the shell of the sausage filling box, extends to the exterior of the sausage filling box and is connected with a detachable L-shaped rotation crank; and anti-skid protrusion stripes are arranged on the outer wall of the detachable L-shaped rotation crank. By adopting the efficient sausage filling machine for sausage processing, automatic-manual integral sausage filling work can be achieved, and thus sausage processing progresses of factories cannot be delayed.

Owner:衡阳县湘衡食品有限公司

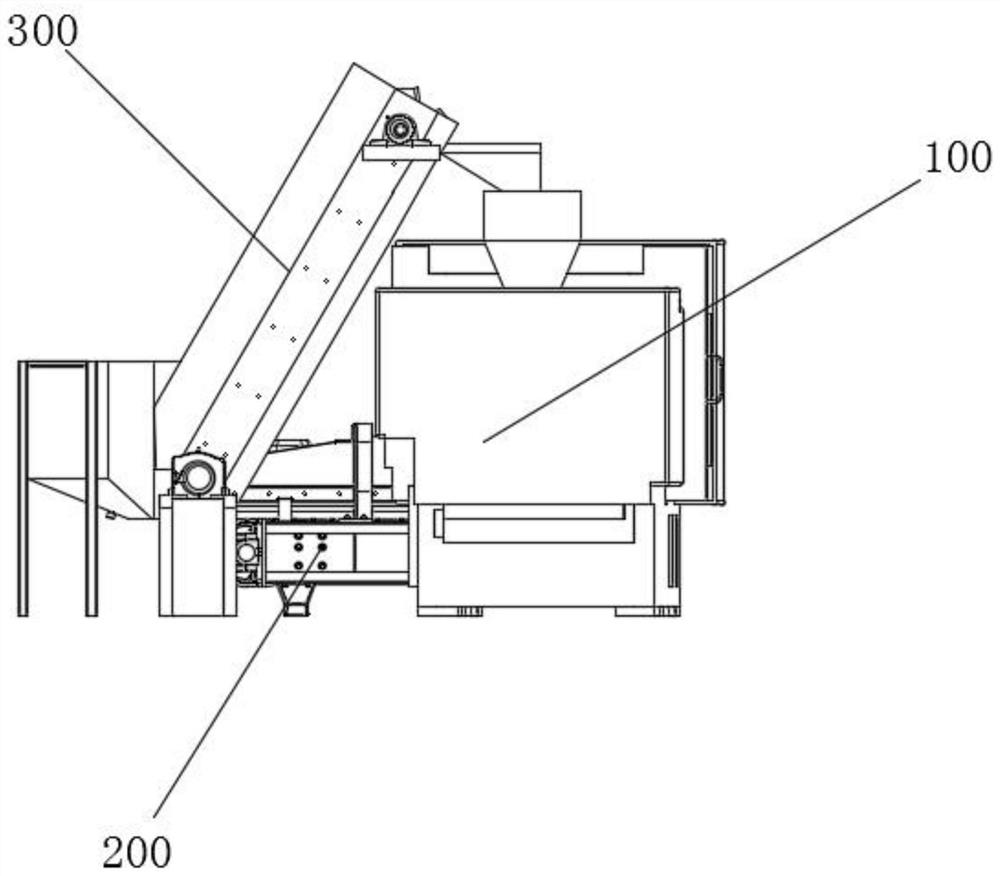

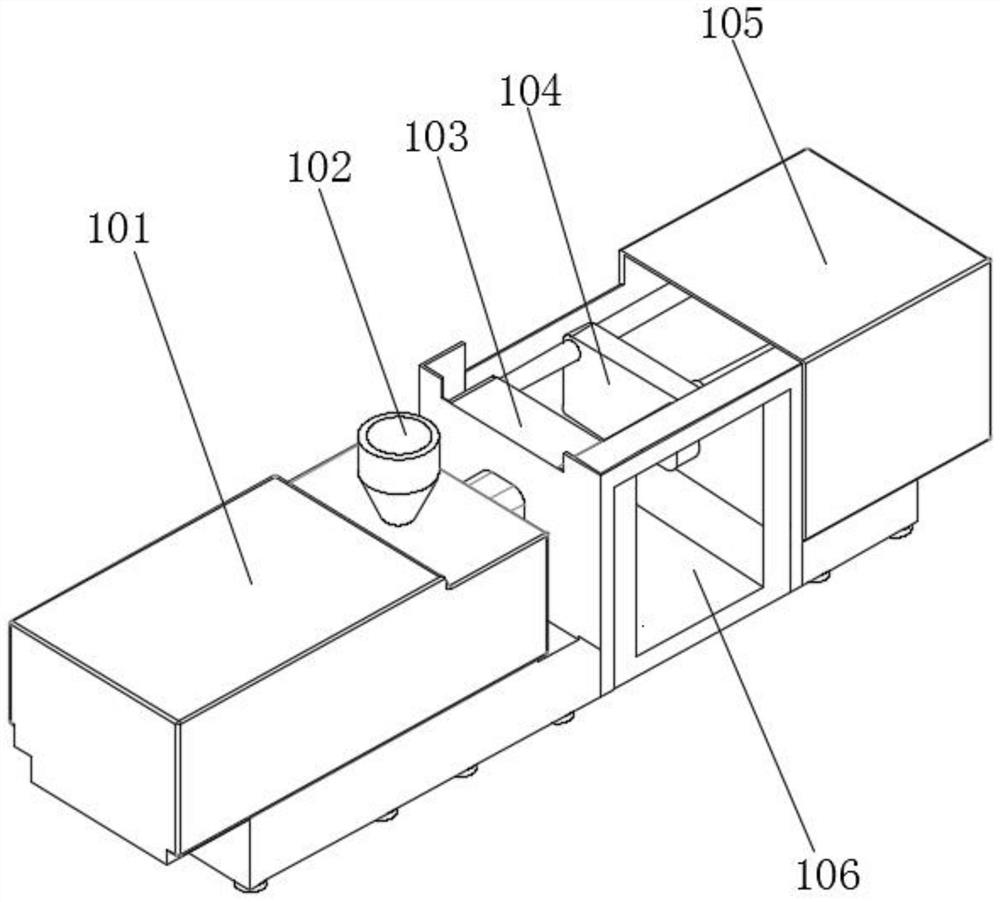

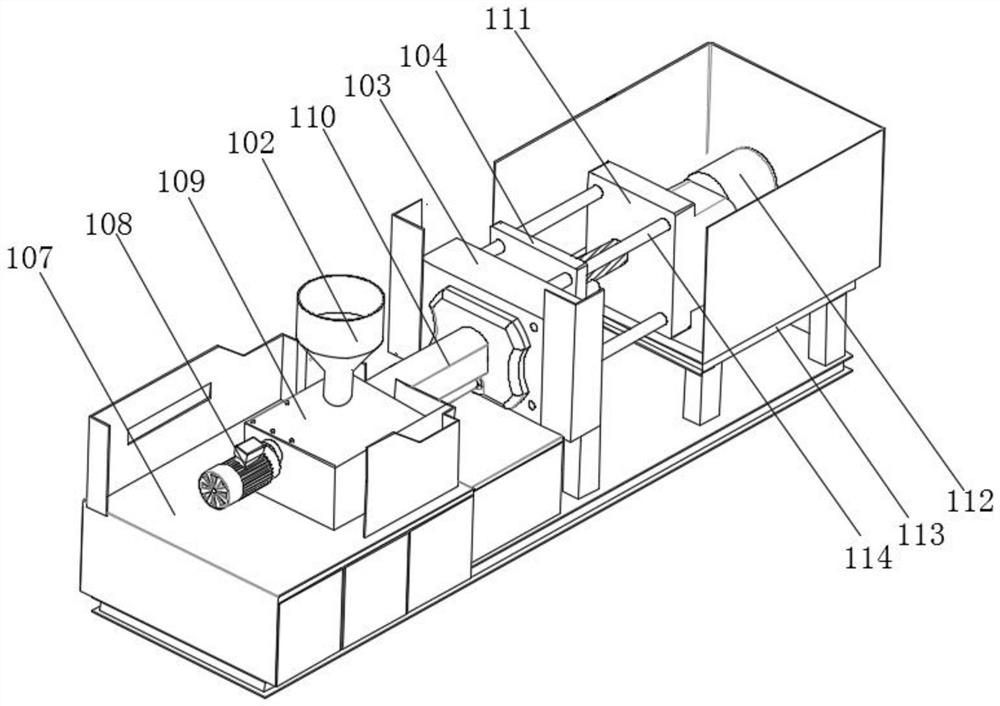

Automatic production equipment for plastic toys

InactiveCN111660535ASimplify the loading processSimple loading processProcess engineeringManufacturing engineering

The invention discloses automatic production equipment for plastic toys. The automatic production equipment for plastic toys comprises a forming mechanism, a discharging conveying mechanism and a feeding conveying mechanism, the feeding conveying mechanism is arranged on one side of the forming mechanism, and the discharging conveying mechanism is arranged on one side of the forming mechanism in apenetrating mode. According to the automatic production equipment for the plastic toys, the feeding position is arranged on the ground, so that the feeding process is simple and rapid; according to the automatic production equipment for the plastic toys, the plastic toys are collected through a receiving hopper and conveyed through a first belt conveyor, so that the produced plastic toys do not affect the subsequent production process, and the fatigue degree of workers is reduced; and according to the automatic production equipment for the plastic toys, the automatic feeding process of a color master batch raw material of the plastic toys is completed through the feeding conveying mechanism, the process of the color master batch raw material to produce the plastic toys is automatically completed through the forming mechanism, the automatic discharging process of the plastic toys is completed through the discharging conveying mechanism, the automation degree is high, and the productionefficiency of the plastic toys is effectively improved.

Owner:马鞍山极趣信息咨询有限公司

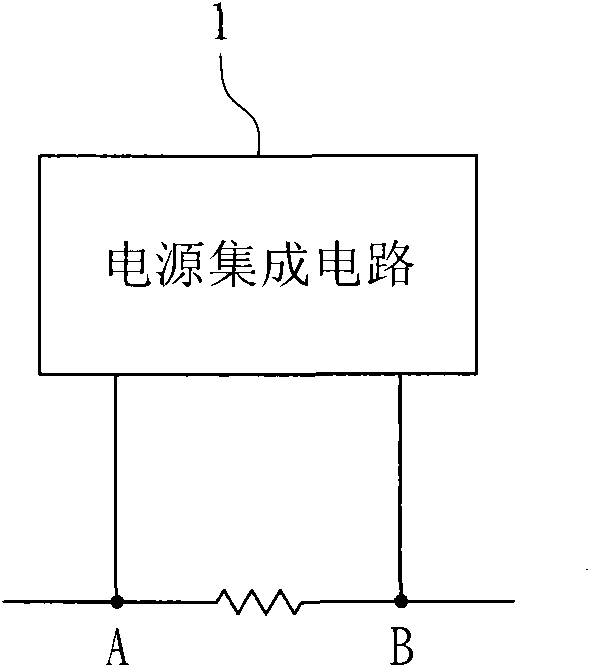

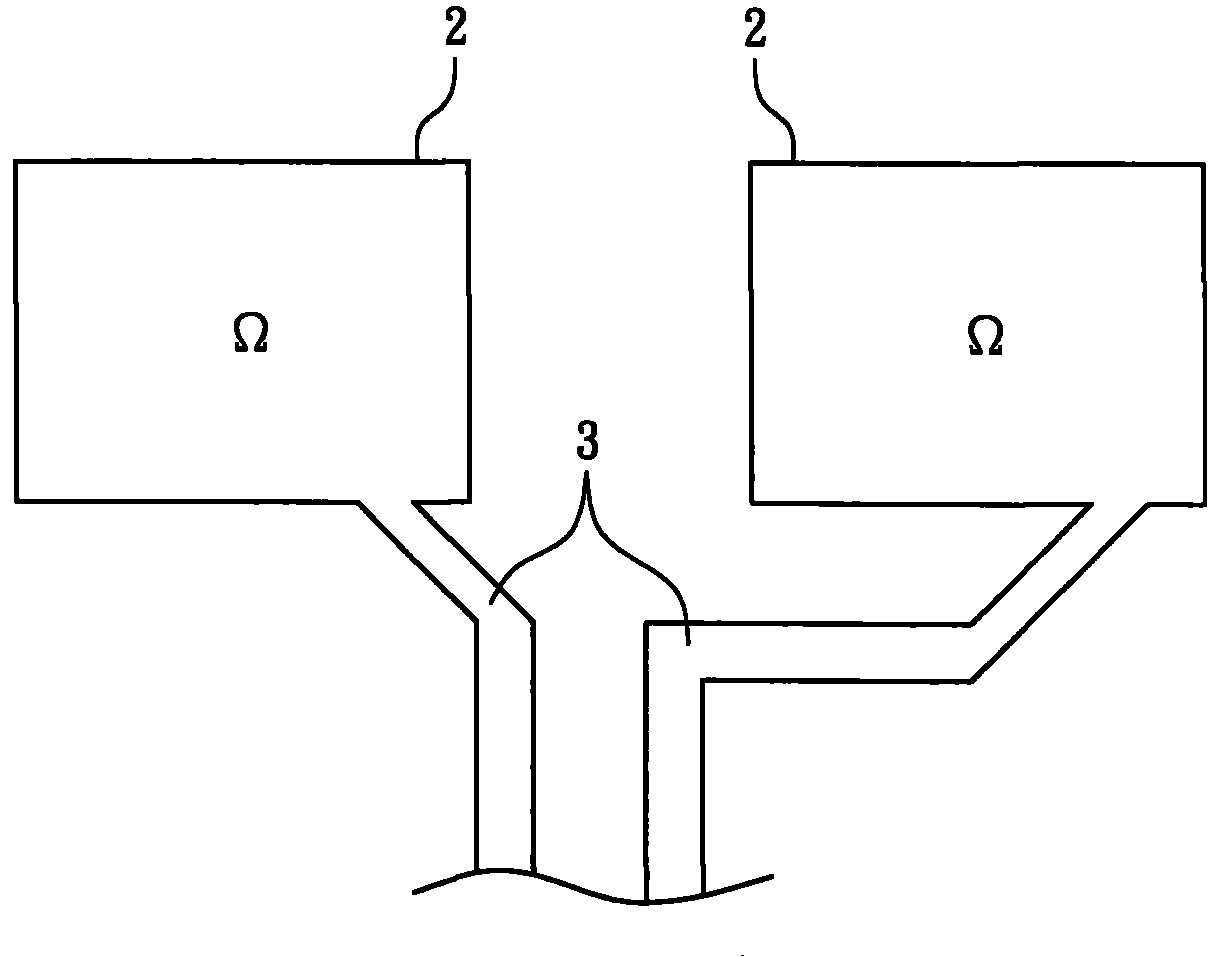

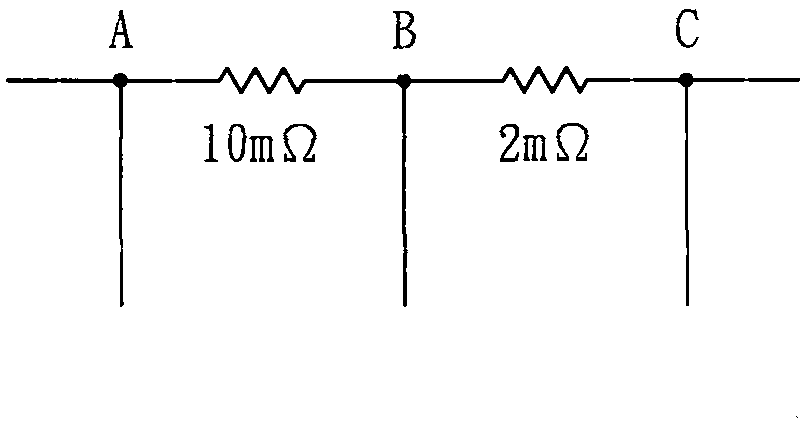

Exact impedance designing method for circuit layout

InactiveCN102073751AIncrease production costAccurately calculate the length and line widthSpecial data processing applicationsElectrical connectionPower flow

The invention relates to an exact impedance designing method for circuit layout. In the invention, a pad of an electronic component and a signal wire of the electronic component are disconnected and separated so as to form non-electrical connection between the pad and the signal wire, but because when the electronic component is welded, a pin can be simultaneously and electrically connected to the pad and the signal wire to ensure that the resistance of the pad is not added to a detection point, thus the current signal measurement can be more exact.

Owner:INVENTEC CORP

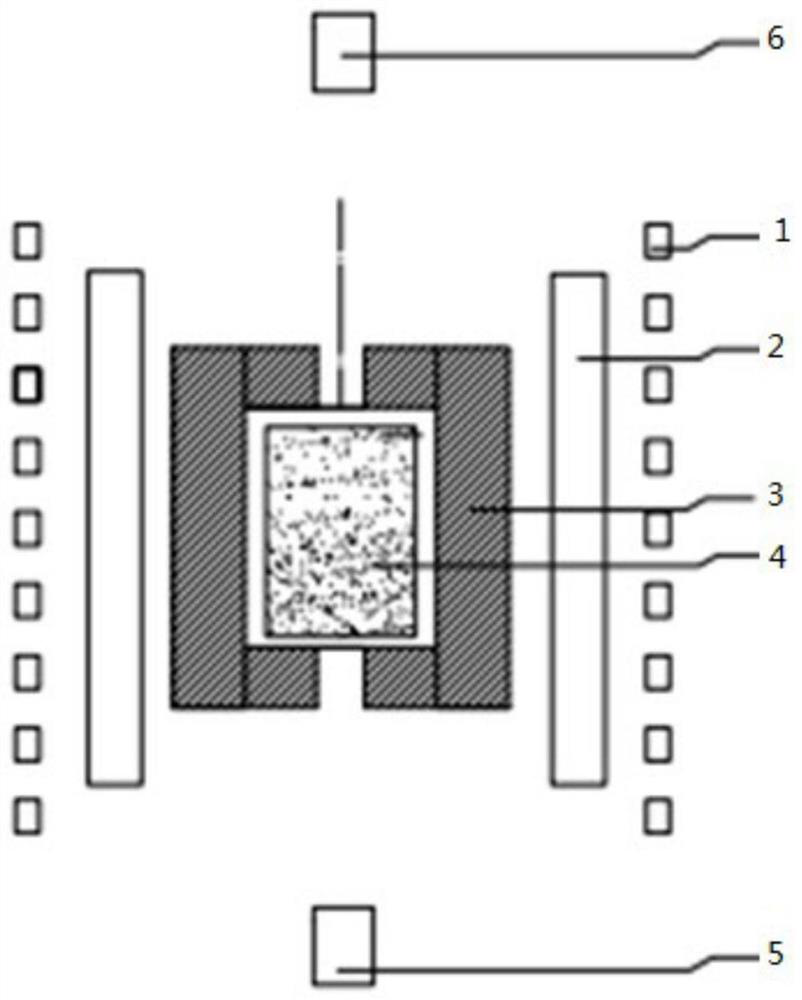

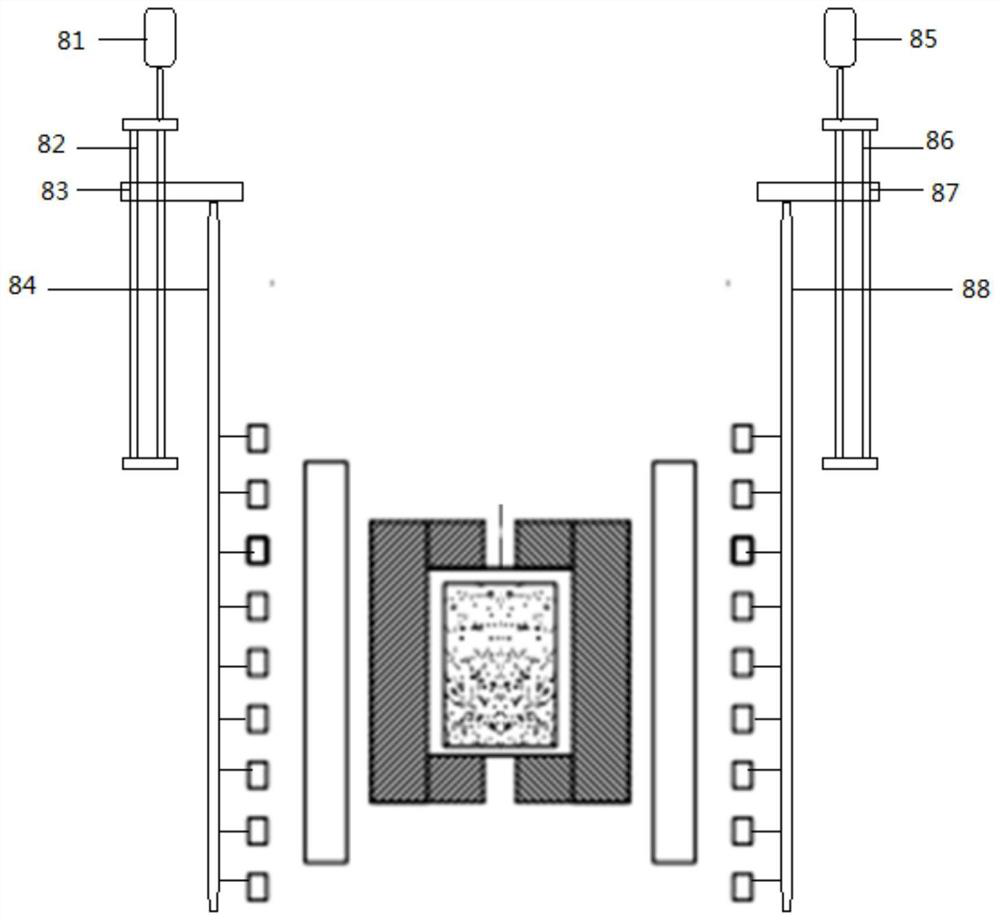

Improved silicon carbide raw material synthesis method

ActiveCN112694090AImprove uniformityWill not affect the production processCarbon compoundsChemical industryCarbide siliconTetrafluoroethylene

The invention discloses an improved silicon carbide raw material synthesis method. The invention mainly relates to the technical field of research and development of a synthesis process of SiC powder for growing single crystals, and mainly aims to achieve the purpose of improving the purity of a synthesized silicon carbide raw material by adding polytetrafluoroethylene into a mixture of carbon powder and silicon powder for synthesizing the silicon carbide raw material and utilizing the purification effect of polytetrafluoroethylene. Firstly, polytetrafluoroethylene is added and mixed, so that the raw materials are mixed more uniformly, and regional aggregation of carbon powder is greatly reduced. In the heating reaction process of raw material synthesis, the position of a coil is moved, so that the carbon powder and the silicon powder fully react, serious carbonization of the region due to the fact that the region is locally at an overhigh temperature all the time is avoided, and the purpose of increasing the yield of silicon carbide raw materials is achieved; and a certain proportion of helium is introduced in the cooling process, and the characteristic that the helium is high in heat conductivity is utilized, so that the cooling time is shortened. The production cost is reduced while the quality of the synthetic silicon carbide raw material is improved.

Owner:北京粤海金半导体技术有限公司

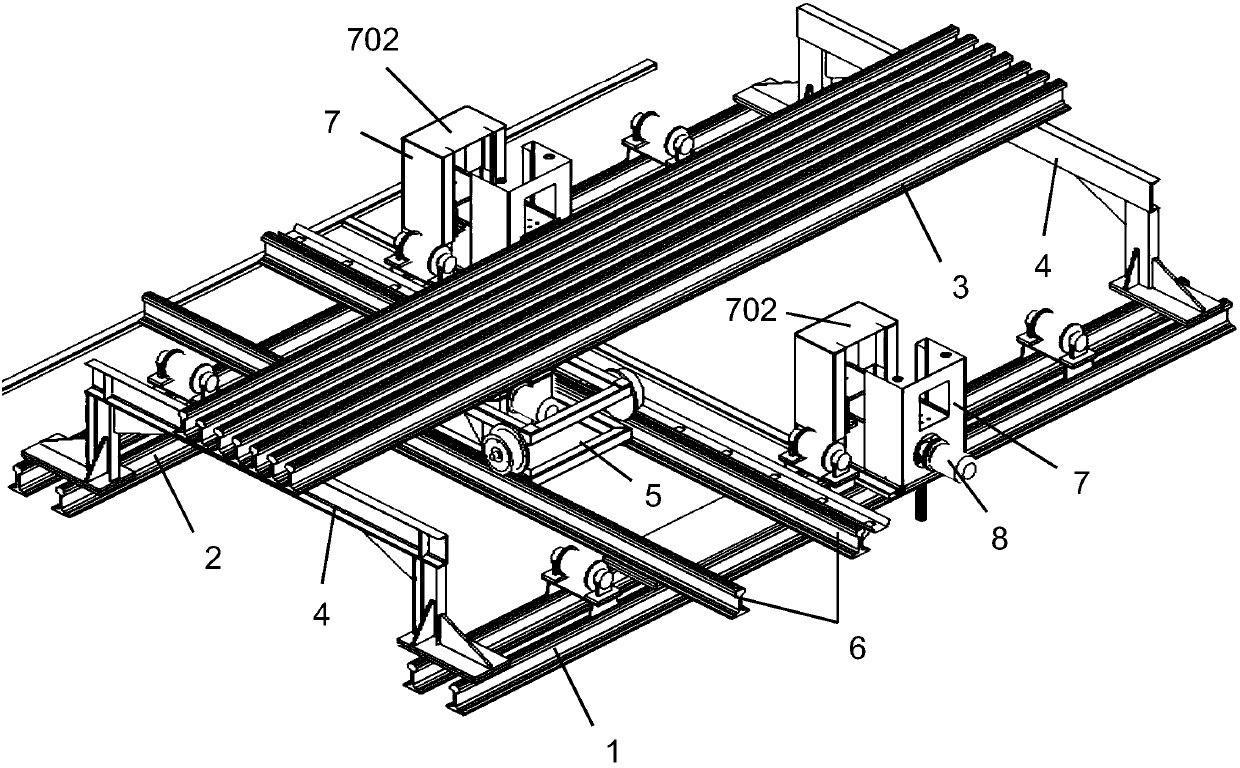

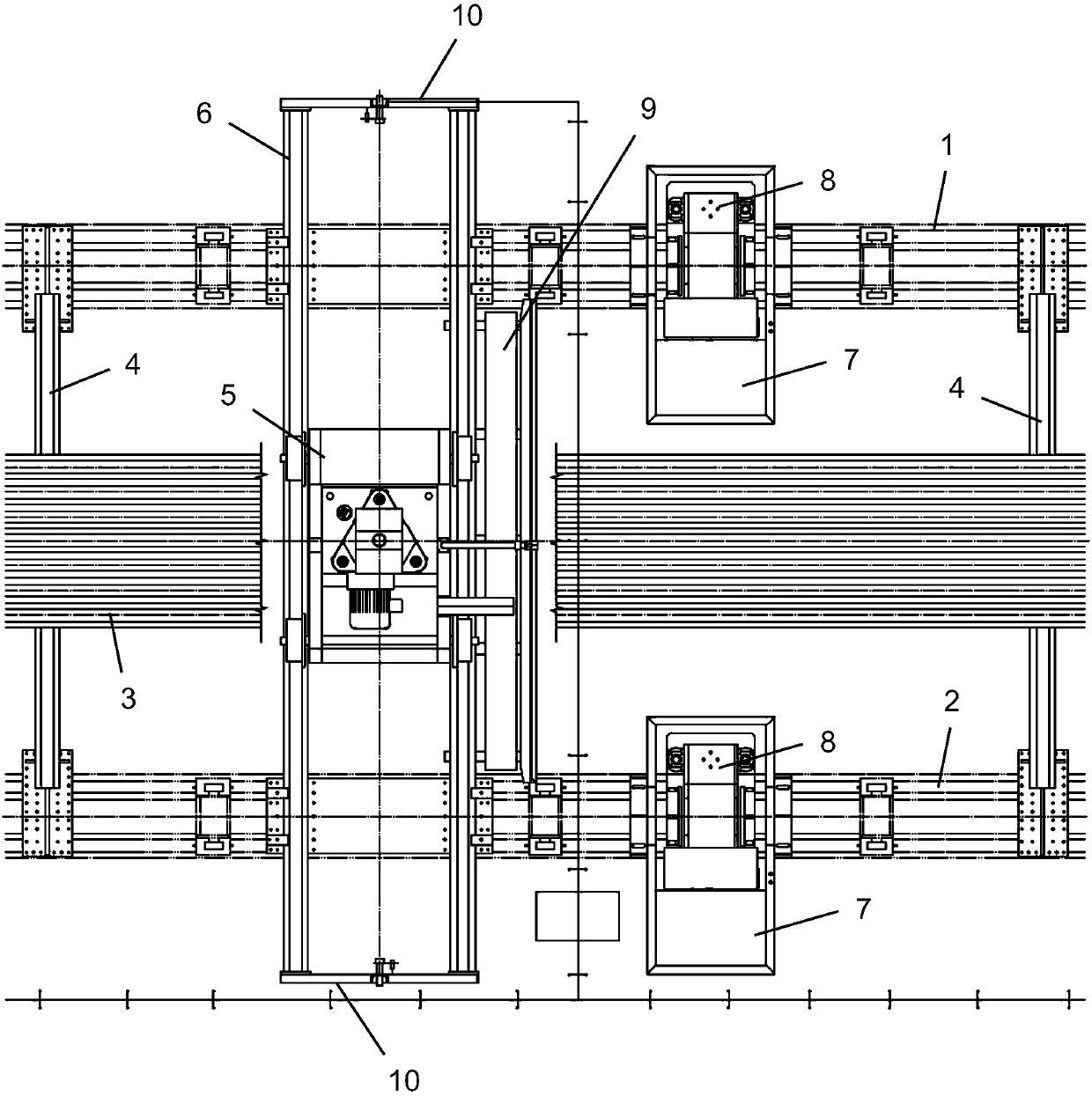

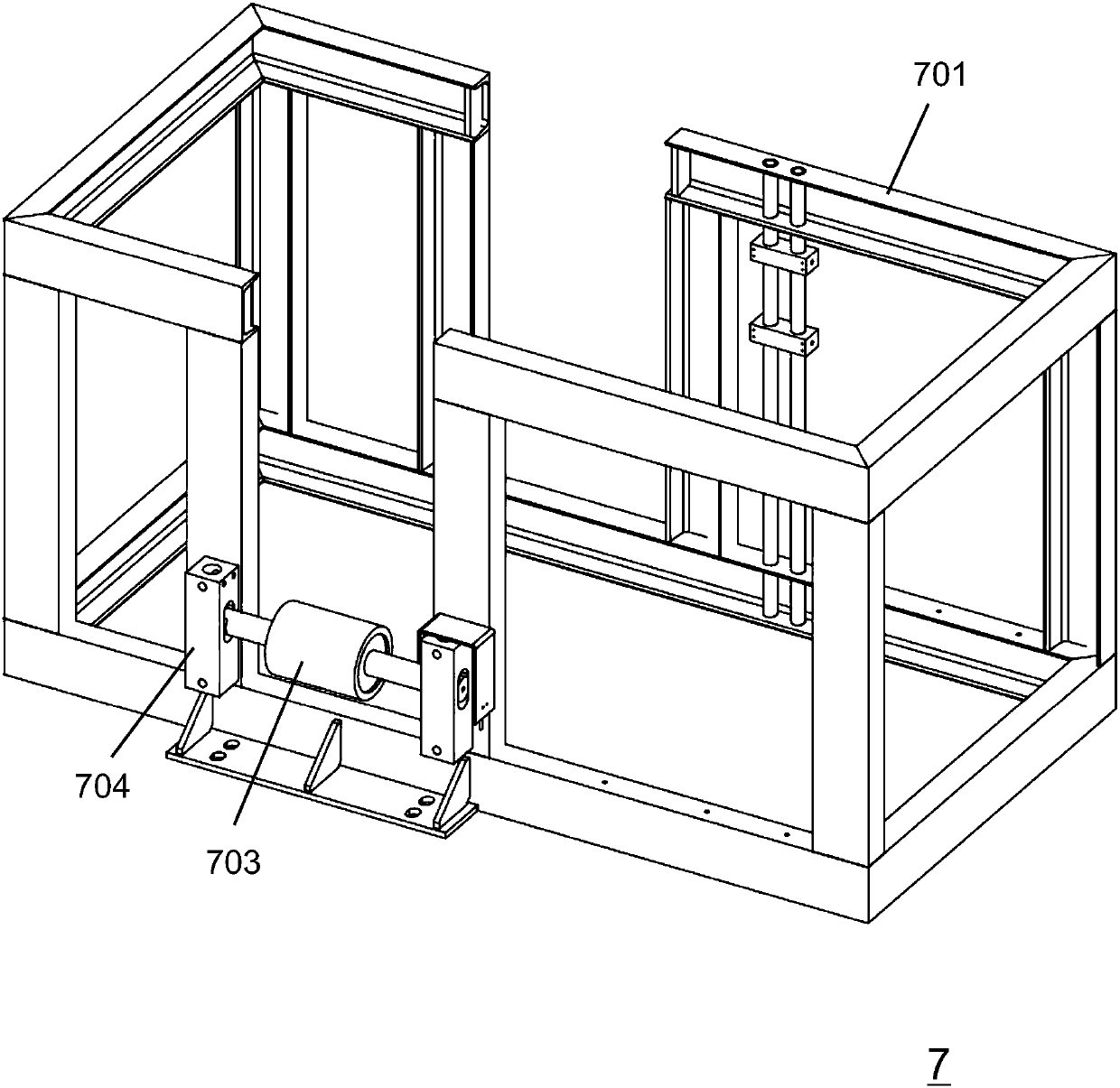

Steel rail translation system and steel rail translation method for case of small distance between steel rail conveying line and ground

ActiveCN107651428ANot floodedNot bothered by rodentsControl devices for conveyorsTotal factory controlStructural engineeringTransfer line

The invention discloses a steel rail translation system and a steel rail translation method for the case of a small distance between a steel rail conveying line and the ground. The steel rail translation system comprises a master control module, a first conveying rail, a second conveying rail arranged in parallel to the first conveying rail, and a plurality of transverse travelling mechanisms arranged on the first conveying rail and the second conveying rail, wherein the master control module is used for synchronously controlling each transverse travelling mechanism; each transverse travellingmechanism comprises a sub-control unit, a bearing unit, a translation unit and a lifting unit; each sub-control unit is used for receiving the instruction of the master control module and controllingthe corresponding transverse travelling mechanism; each bearing unit is used for bearing steel rails; each translation unit is used for translating the steel rails on the corresponding bearing unit towards the directions of the first conveying rail and the second conveying rail separately; and each lifting unit is used for placing the steel rails translated by the corresponding translation unit onto the first conveying rail and the second conveying rail separately. The steel rail translation system and the steel rail translation method are applicable to the case of a small distance of not greater than 1000mm between the steel rail conveying line on a welded rail site and a ground elevation.

Owner:上海瑞纽机械股份有限公司

Composite material and preparation method thereof

PendingCN114226454APhysical properties are similarGood deformation consistencyMetal rolling arrangementsAluminum compositesMagnesium alloy

The invention provides a preparation method of a magnesium-aluminum composite material, which comprises the following steps of: respectively processing a magnesium alloy and an aluminum alloy into shapes of which at least one surfaces can be matched with each other in a concave-convex manner, mutually assembling the surfaces of the magnesium alloy and the aluminum alloy which can be matched with each other in the concave-convex manner to obtain an extrusion blank, and preheating and extruding the assembled extrusion blank to obtain a magnesium-aluminum double-layer plate, and finally, the magnesium alloy layers in the magnesium-aluminum double-layer plate are oppositely arranged and stacked, rolling is conducted, and the aluminum-magnesium-aluminum three-layer composite material is obtained. The magnesium / aluminum composite material with excellent bonding performance and mechanical performance is successfully prepared, and the problems that a single-component magnesium alloy plate is low in mechanical performance, poor in corrosion resistance and insufficient in surface coloring ability are solved.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

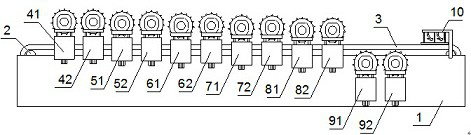

Automatic mask production line

ActiveCN112315085AAvoid position shifting or even shakingQuality assuranceProtective garmentClothes making applicancesProduction lineFusion welding

The invention discloses an automatic mask production line; a mask placed between limiting plates is flattened through an arranged flattening pressing plate in an ear belt fusion welding work process of the mask when the mask is automatically produced, and when the flattening pressing plate presses the bottom end, the flattening pressing plate presses a second movable pressing block to drive a leveling limit mechanism to operate; and finally, a T-shaped movable limiting plate and a movable pressing plate which are arranged in the leveling limiting mechanism are driven to limit and press the edge side of the mask, so that the mask can be prevented from deviating or even shaking during ear belt fusion welding work, and the quality of the ear belt fusion welding work is guaranteed. Therefore,the mask production working efficiency can be improved, and economic benefits are improved while the mask quality is guaranteed.

Owner:重庆市宏冠医疗设备有限公司

Manufacturing method for leather capable of preventing and treating tinea pedis

ActiveCN105316439AGood warmth functionGood sweat wicking abilityAntimycoticsTanning treatmentPharmaceutical SubstancesFoot ringworm

The invention relates to a manufacturing method for leather, and discloses a manufacturing method for the leather capable of preventing and treating tinea pedis. The manufacturing method comprises the following steps that a, medicine is proportioned and milled into powder for standby application; b, medicine powder is added into water to form a mixed solution, and the mixed solution is stirred intermittently; and c, an animal hide is subjected to water squeezing, and then is naturally air-dried and dried by baking in sequence. According to the manufacturing method for the leather capable of preventing and treating the tinea pedis, a wet-salted bovine hide is immerged into the medicine, and then the wet-salted bovine hide is manufactured into leather shoes or shoe pads; the sizes of the leather shoes or shoe pads cannot be increased, and the wearing comfort cannot be influenced; the medicine has a preventive effect; when the leather shoes or the shoe pads are wore by people, the tinea pedis is prevented and treated; the treatment method is simple, effective, convenient and economical; meanwhile, the medicine effect is lasting, effect starting is fast, and irritation and side-effects are avoided. Components of the medicine are easy to get, high in quality and low in cost.

Owner:QUANZHOU GONGJIN LEATHER CO LTD

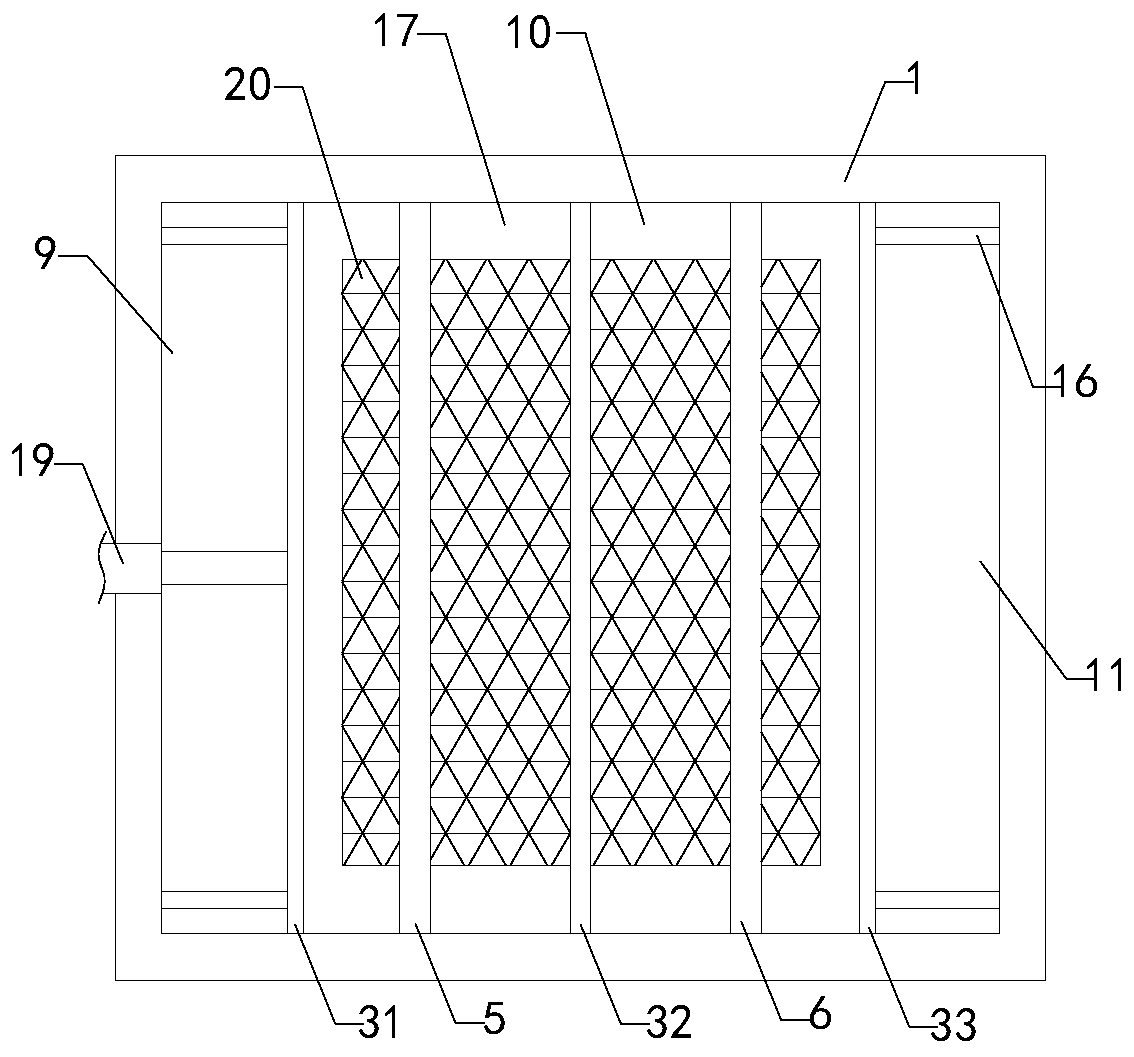

Core material of vacuum insulation panel and manufacturing method thereof

The invention relates to a vacuum insulated panel core material and a manufacturing method thereof. the core material is small in heat conductivity coefficient and low in cost and comprises 70wt% to 100wt% of short chopped glass fiber strands with diameters in a range of 6 microns to 13 microns and lengths in a range of 4 millimeters to 20 millimeters and 0wt% to 30wt% of glass fiber cotton with diameters in a range of 1.0 microns to 4 microns and lengths in a range of 1 millimeters to 5 millimeters, wherein the short chopped glass fiber strands are produced through a strand drawing method, and the glass fiber cotton is produced through a flame method flame method. According to the manufacturing method for core panels, multi-layer liquid adding and multi-layer vacuum dewatering are used, the heat conductivity coefficient of the vacuum insulated panel core material is below 0.03W / m.k, and the heat conductivity coefficient of the vacuum insulated panel is below 0.0025 W / m.k, the heat conductivity coefficient is lower than that of a glass fiber cotton core material 100% produced through the flame method, the insulating effect is good, the manufacture cost of the vacuum insulated panel core material is saved greatly simultaneously, and the quality is stable and controllable.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

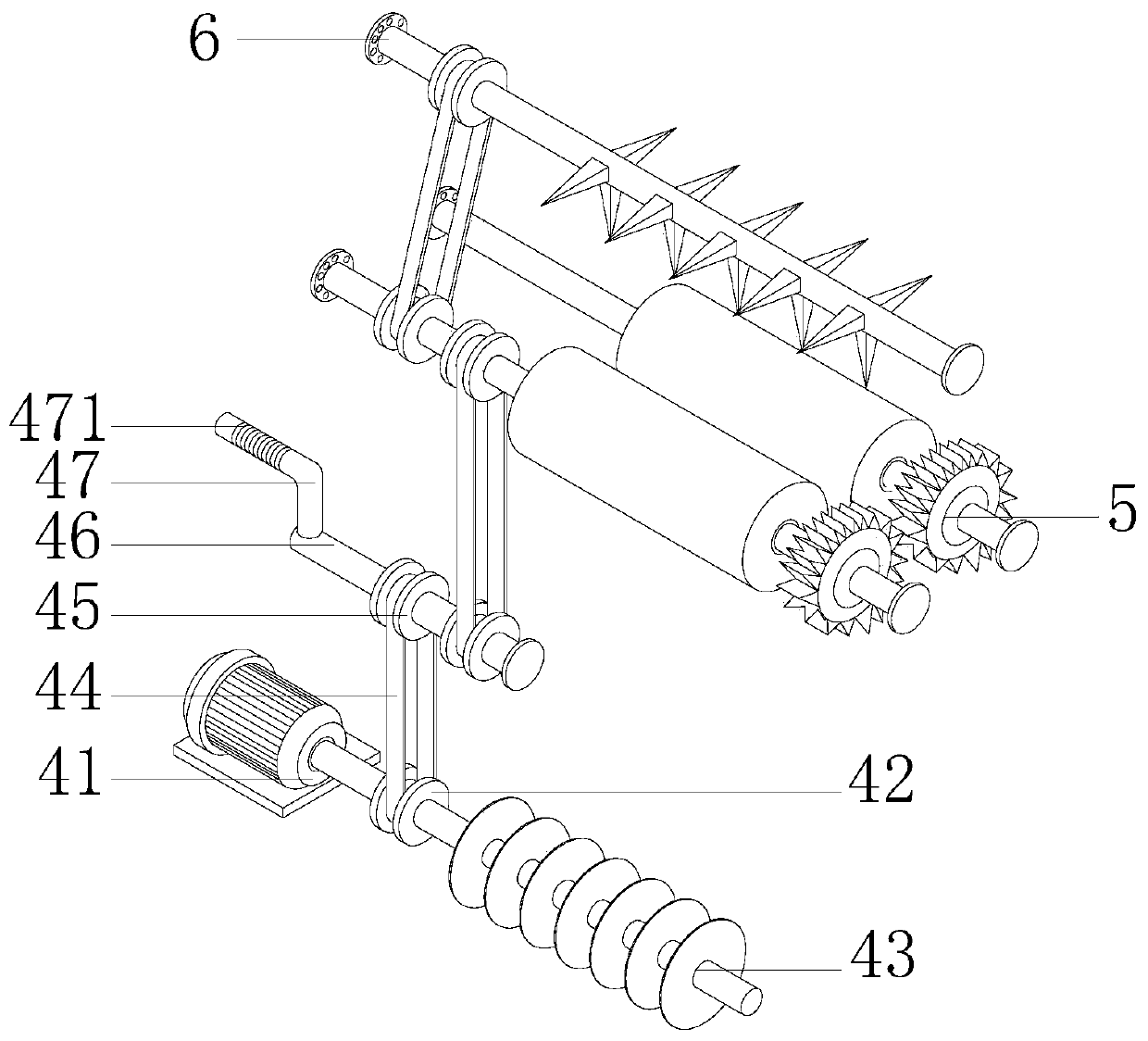

A flue gas treatment device for power cord production

ActiveCN109107764BEasy to handleWill not affect the production processGas treatmentDispersed particle separationRubber ringActivated carbon filtration

The invention relates to the technical field of auxiliary devices for producing power lines, in particular to a flue gas treatment device for producing a power line. The flue gas treatment device hasthe advantages that the treatment effect of waste gas is improved, the practicability is improved, an activated carbon filter screen is desorbed, without shutdown, the operation is simple, and the production process of the power line is not influenced. The flue gas treatment device comprises a box body; a working cavity is formed in the box body; an air inlet pipe is arranged at the left end of the box body; an air inlet fan is arranged at the air inlet pipe; the flue gas treatment device further comprises a transverse baffle plate, a left baffle plate, a right baffle plate, multiple groups ofpositive electrode pipes and multiple groups of negative electrode pipes; the working cavity is divided into an upper cavity and a lower cavity by the transverse baffle plate; the upper cavity is divided into a first cavity, a second cavity and a third cavity from left to right by the left baffle plate and the right baffle plate; the flue gas treatment device also comprises multiple groups of insulated rubber rings, multiple groups of upper connecting rods, multiple groups of lower connecting rods, a high-voltage transformer, two groups of limiting rods, a fixed frame, a telescopic cylinder,a telescopic rod, an activated carbon fibrofelt, multiple groups of air spraying pipes, a water tank, a heating rod, an air pump and an air delivery pipe.

Owner:ZHENJIANG ZHONGJIA ELECTRICAL CO LTD +2

A ceramic tile trimming device

ActiveCN109016099BReasonable designImprove product qualityAuxillary shaping apparatusBrickElectric machinery

The invention discloses a ceramic tile edge trimming device, which comprises a control box, a drive motor, a frame, a conveyor belt, two sets of working cutting machine components installed on the front and rear sides of the frame, two sets of spare cutting machine components and two sets of edge pressing plates . The ceramic tile edge trimming device of the present invention has a reasonable design, and by setting two sets of cutting machine components, the working cutting machine component and the standby cutting machine component, the cutting saw blade can be easily replaced during the production process, which is safer and will not affect the production process at the same time. High efficiency; by lowering the installation height of the cutting machine components from left to right, the cutting depth of each cutting machine component can be different, and layered cutting can be realized; the edge of the tile can be easily removed by pressing down the edge plate, and The tiles are uniformly pressed and removed at the edge holder, which can realize the centralized recycling of tile edge waste, and the tiles will not be damaged during the removal process.

Owner:陈全民

A method for recovering low-temperature waste heat from cooling circulating water in a sugar factory

InactiveCN103898242BReduce the temperatureSave energySugar juice boiling/evaporationThermal energyPlate heat exchanger

Owner:翟东 +1

A kind of noodle cake unboxing method

ActiveCN108157419BImprove aestheticsSolve the technical problem of easy adhesion and difficult to remove the boxDough processingProcess engineeringInstant noodle

The invention relates to the technical field of instant noodles, particularly to a method for separating a noodle cake from a box. The method comprises: 1) carrying out hot air drying on noodle cake placed in a bowl box to achieve a half-dry state; 2) under a hot air drying condition, carrying out downward blowing when the half-dry noodle cake obtained in the step 1) is conveyed by a conveying belt; and 3) separating the noodle cake obtained in the step 2) from the bowl box. With the method of the present invention, the problem of the adhesion between the noodle cake and the bowl tool during the hot air drying in the prior art can be solved, the operation is easy, and the separation effect is excellent.

Owner:TINGYI (CAYMAN ISLANDS) HOLDING CORPORATION

A method for extracting antithrombin III and various functional proteins from the precipitation of component IV of plasma cohn method

ActiveCN105669858BRaise quality standardsHigh quality attributeSerum albuminPeptide preparation methodsBlood plasmaSediment

Owner:LANZHOU INST OF BIOLOGICAL PROD

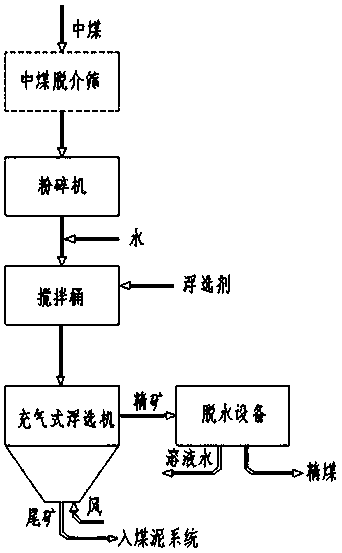

Process for extracting clean coal from middling coal

PendingCN110694791AWill not affect the production processSimple processSolid separationPhysical chemistryPre treatment

Owner:XIAN ZHONGYUAN MACHINERY CO LTD

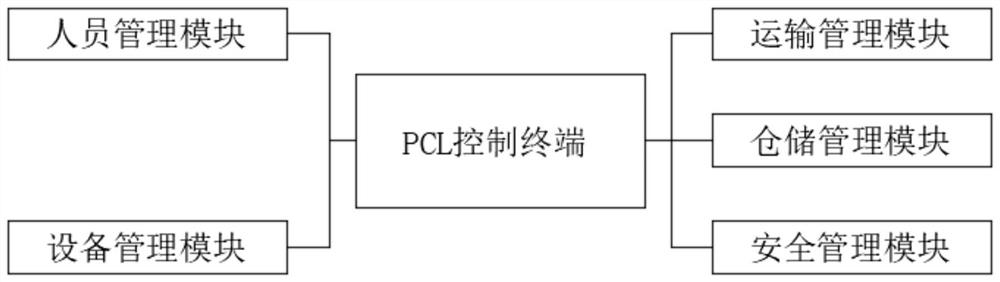

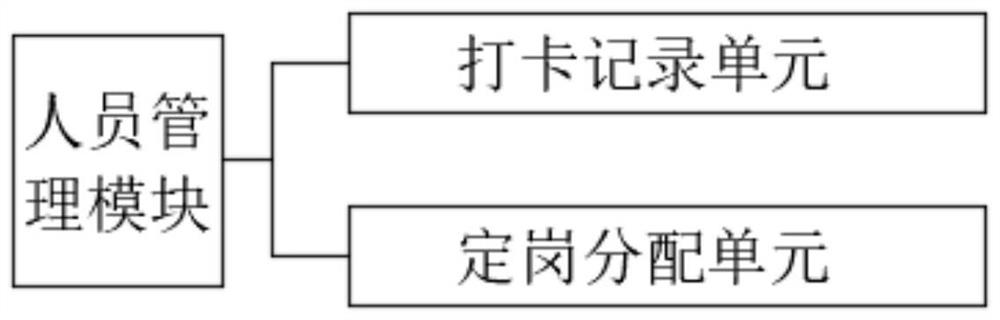

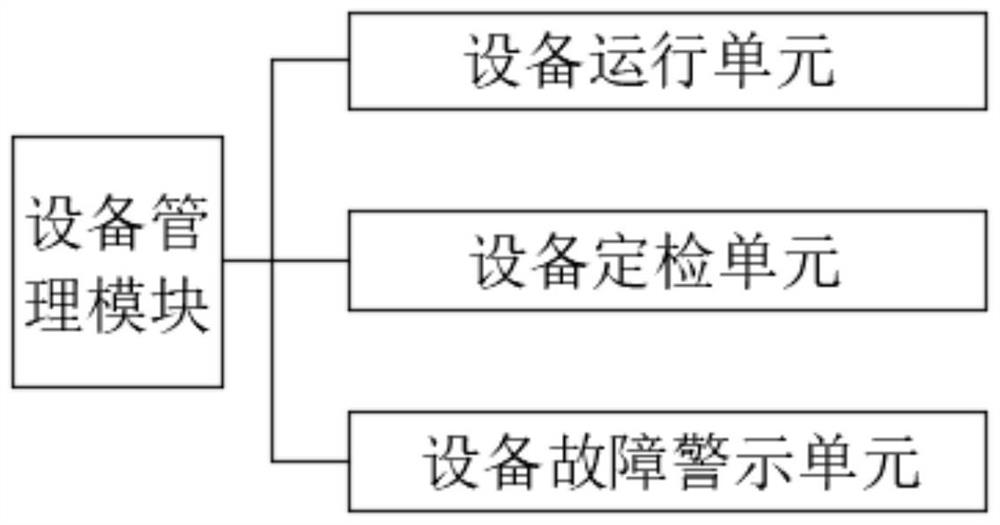

Smart factory management system

PendingCN114089703AWill not affect the production processEfficient and precise transportationTotal factory controlProgramme total factory controlSmart factoryManagement system

The invention discloses a smart factory management system which comprises a PCL control terminal, a personnel management module, an equipment management module, a transportation management module, a warehouse management module and a safety management module. The system has the beneficial effects that the personnel management module is arranged, personnel allocation can be carried out according to production requirements, distribution according to needs can be achieved, and then it is ensured that the production process is not affected; a transportation management module is arranged, so that a transportation route can be planned, and meanwhile, corresponding finished products can be transported in advance in a targeted manner according to the transportation level, so that efficient and accurate finished product transportation can be realized; and the warehouse management module is arranged to manage finished product storage and prevent the finished products from being stacked disorderly, and meanwhile, the temperature and humidity of the warehouse can be monitored to ensure the storage environment.

Owner:NINGBO BIYI ELECTRIC APPLIANCE

Blade de-icing device and method for a wind power plant

ActiveCN108252878BWill not affect the production processFlexible configurationMachines/enginesWind energy generationControl cellEngineering

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com