Steel rail translation system and steel rail translation method for case of small distance between steel rail conveying line and ground

A translation system, small spacing technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problem of long; second, the mechanical and electrical devices are placed below the floor, and the rail traverse system cannot be arranged. and electrical installations, arranging rail traverse systems, etc., to prevent slippage accidents, reduce the number of spare parts, and reduce the failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

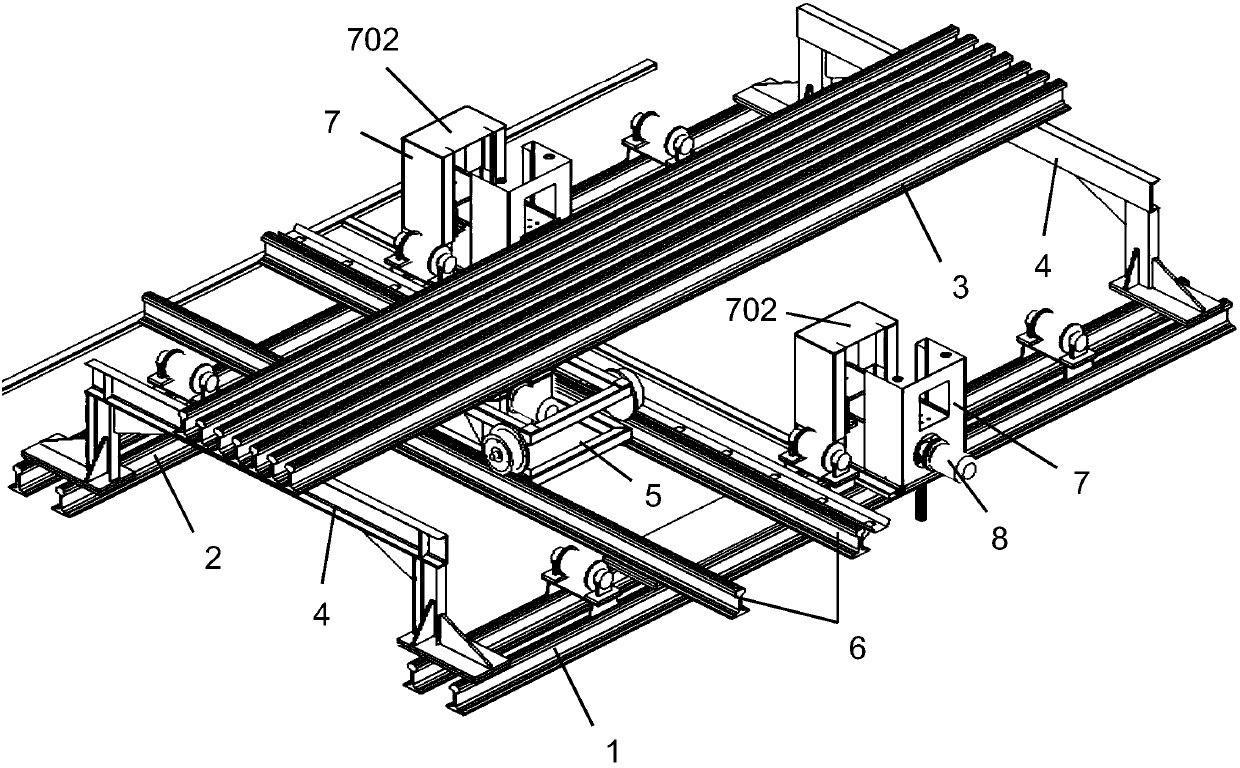

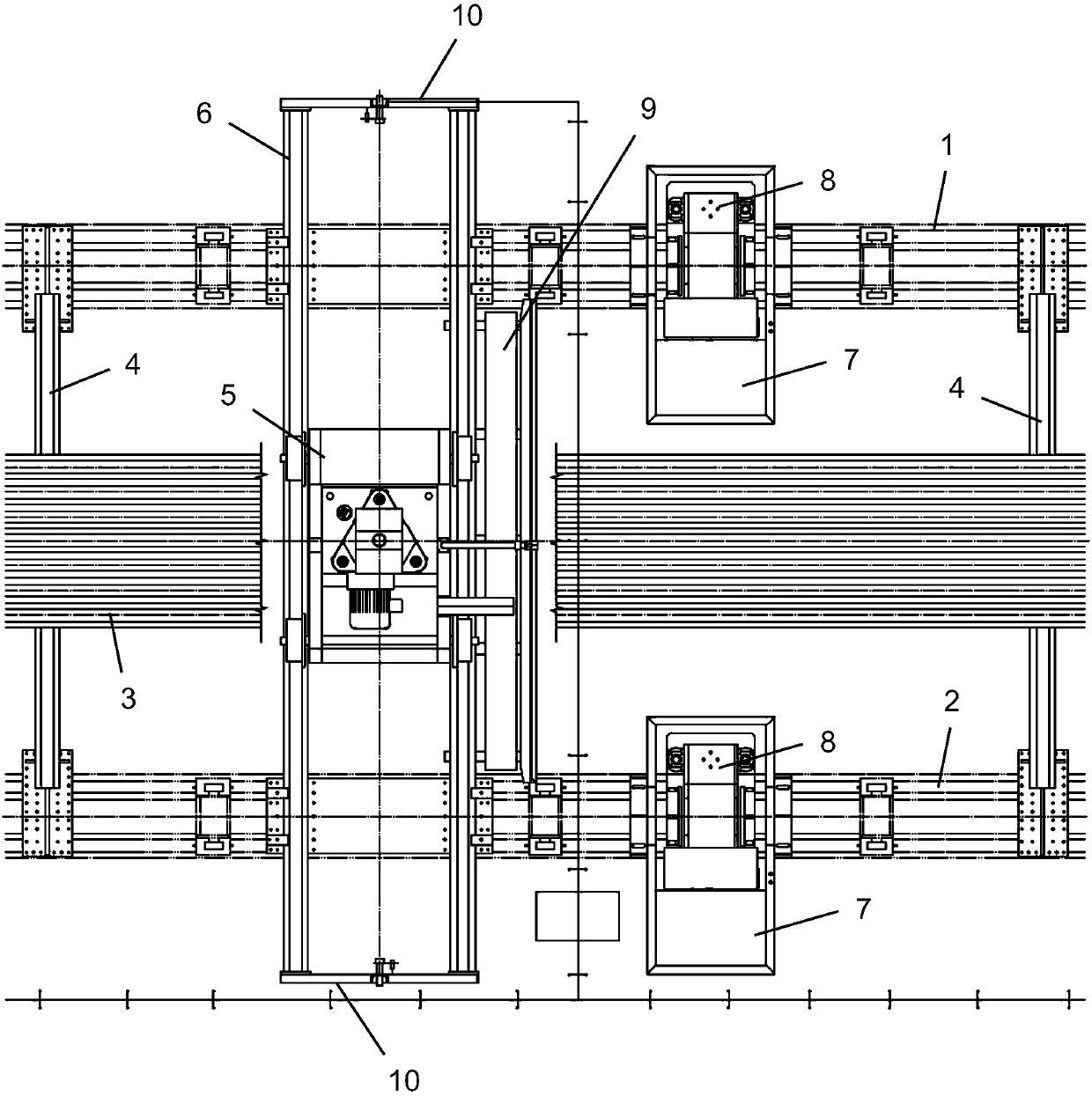

[0057] Please combine Figure 1 to Figure 4 As shown, the rail translation system provided by the present invention for the small distance between the rail conveyor line and the floor includes: a master control module, a first conveyor track 1, a second conveyor arranged in parallel with the first conveyor track 1 Track 2, and several sets of traverse mechanisms arranged on the first conveying track 1 and the second conveying track 2. The master control module is used to synchronously control each set of traverse mechanisms. In this embodiment, 8 sets of traverse mechanisms are used. 3 Use 100m rails.

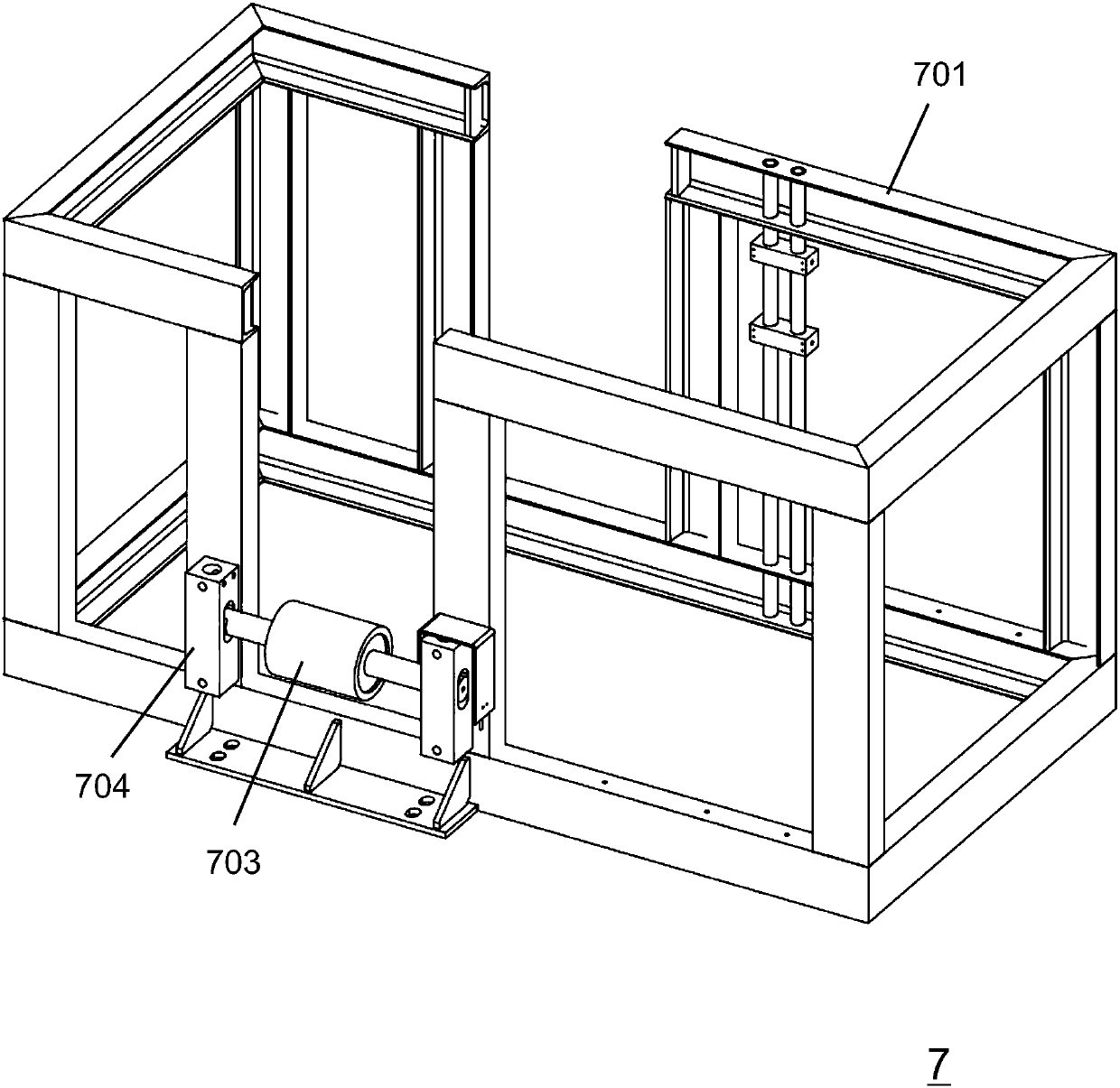

[0058] Preferably, the lateral movement mechanism includes: a sub-control unit, a carrying unit, a translation unit, and a lifting unit. The sub-control unit is used to receive synchronization instructions from the general control module, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com