Interface coating modification device and method for functional yarn

A yarn and coating technology, which is applied in the field of functional fiber preparation, can solve the problems of limiting the use range of polyelectrolytes, the concentration is not easy to be too high, and the fabric has poor air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

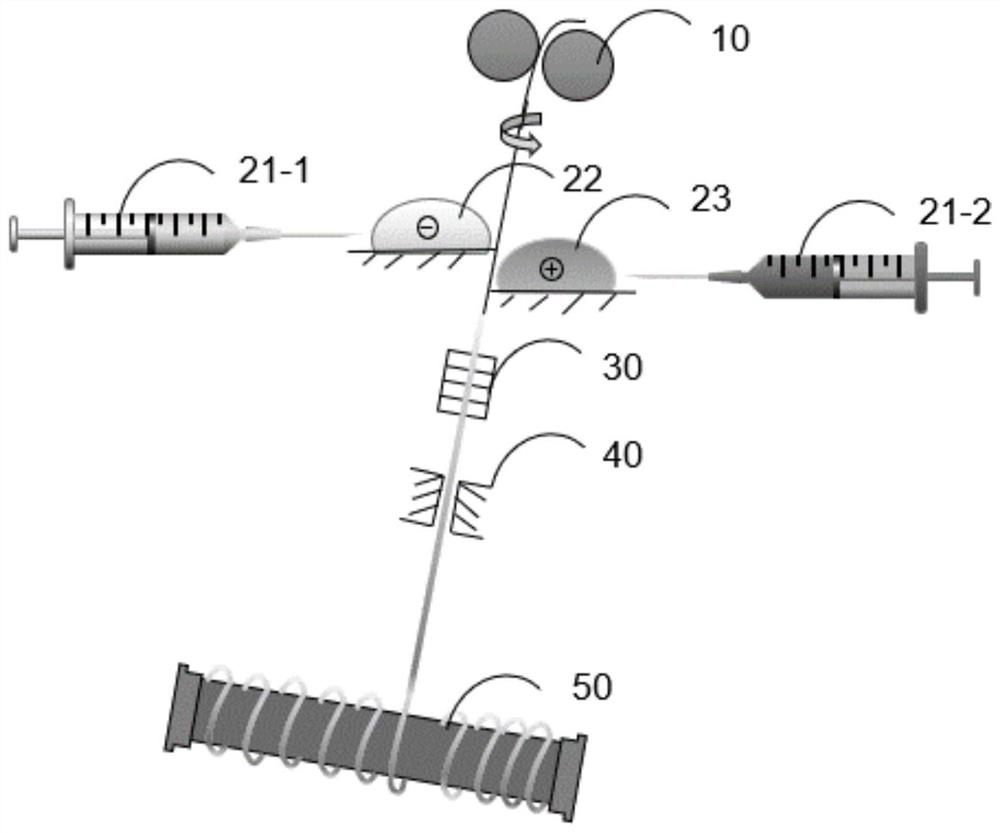

[0054] A method for coating and modifying functional yarns is produced and prepared by using an interface coating and modifying device for functional yarns. see figure 1 As shown, the device includes a yarn feeding module 10 , a yarn rotating module 30 , a modifying fluid coating module 20 , a drying module 40 and a winding module 50 . The feeding module 10 is realized by a feeding roller, and the yarn rotating module 30 can be realized by a twisting device. The modified liquid coating module 20 includes two symmetrically arranged carrying containers 22, 23 (the height difference of the two carrying containers is 20mm) for holding the cationic polyelectrolyte solution and the anionic polyelectrolyte solution respectively, and The anionic polyelectrolyte extruding device 21-1 and the cationic polyelectrolyte extruding device 21-2 respectively matched with the carrying containers 22, 23 are used for continuously supplying the cationic polyelectrolyte solution and the anionic po...

Embodiment 2

[0061] A method for coating and modifying functional yarns. Compared with Example 1, the difference is that in step S1, the concentration of polyethyleneimine solution is 2 mg / mL, and the concentration of polyacrylic acid solution is 2 mg / mL In step S2, the modified liquid coating module 20 includes two electrostatic spraying devices, which are used to spray polyethyleneimine solution and polystyrene sulfonic acid solution from the polyester yarn respectively during the rotation and movement of the polyester yarn. Both sides of the polyester yarn are sprayed onto the surface, so that the polyethyleneimine solution and the polystyrene sulfonic acid solution are evenly adhered to the surface of the polyester yarn to form a water-insoluble polyelectrolyte composite film. Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0062] The functional polyester yarn prepared in this example has a dyeing rate of methylene blue of 27% and a moisture absor...

Embodiment 3

[0064] A method for coating and modifying functional yarns. Compared with Example 1, the difference is that in step S1, silver ions are added to polyethyleneimine solution and polyacrylic acid solution. Others are substantially the same as in Embodiment 1, and will not be repeated here.

[0065] The functional polyester yarn prepared in this example can inhibit the growth of Staphylococcus aureus, and the bacteriostatic rate can reach 85.7% in 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com