A ceramic tile trimming device

A ceramic tile and trimming technology, which is applied in the field of ceramic tile cutting, can solve the problems of low work efficiency, waste cannot be recycled centrally, waste of resources, etc., and achieve the effect of improving the quality of porcelain products, improving market competitiveness, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

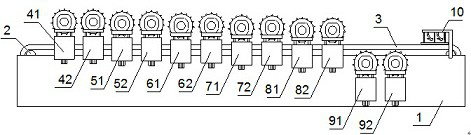

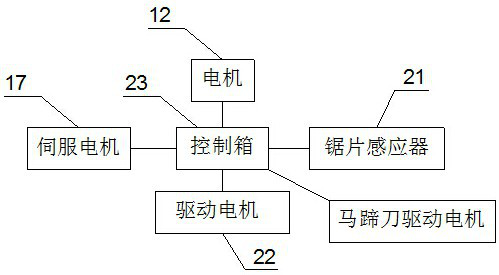

[0024] see Figure 1-3 , a ceramic tile trimming device, including a control box 23, a drive motor 22, a frame 1, a conveyor belt 3, two groups of working cutting machine components installed on the front and rear sides of the frame 1, two groups of spare cutting machine components and two groups of pressing The side plate 10; the driving motor 22 drives the driving wheel 2 to move, and the driving wheel 2 drives the conveyor belt 3 to move;

[0025] The working cutter assembly includes a cutter assembly a41, a cutter assembly b51, a cutter assembly c61, a cutter assembly d71, a cutter assembly e81 and a lower cutter assembly 91;

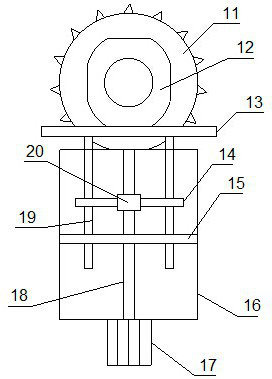

[0026] The working cutter components are all installed on the frame 1, the cutter component a41, the cutter component b51, the cutter component c61, the cutter component d71 and the cutter component e81 are installed from left to right, and the installation height is from left to The right is lowered successively, and the cutting blades 11 of the c...

Embodiment 2

[0032] On the basis of Example 1, please refer to Figure 4 , the edge clamping plate 10 includes a pressing plate 26, a mounting bracket 27, two connecting rods 28, two horseshoe knife drive motors, two horseshoe knives 25 and some return springs 24; the mounting bracket 27 is fixedly installed on the frame 1, the upper end of the mounting bracket 27 is hingedly connected with the horseshoe knife 25 respectively through two connecting rods 28, the horseshoe knife driving motor is installed on the connecting rod 28, the horseshoe knife driving motor drives the horseshoe knife 25 to rotate, and the upper end of the mounting bracket 27 passes through several Return spring 24 is connected with pressing plate 26; During work, horseshoe knife driving motor drives horseshoe knife 25 to rotate, and horseshoe knife 25 presses pressing plate 26, and pressing plate 26 presses down the ceramic tile edge, realizes the ceramic tile edge after cutting is removed, because in ceramic tile Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com