Ammonia recovery method for gas mixture in hydrogen cyanide production

A mixed gas and ammonia recovery technology, applied in the field of ammonia recovery, can solve the problems of increased hydrogen cyanide production cost, blockage of trays, poor ammonia recovery effect, etc., and achieve the effects of reducing production cost, production process safety, and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

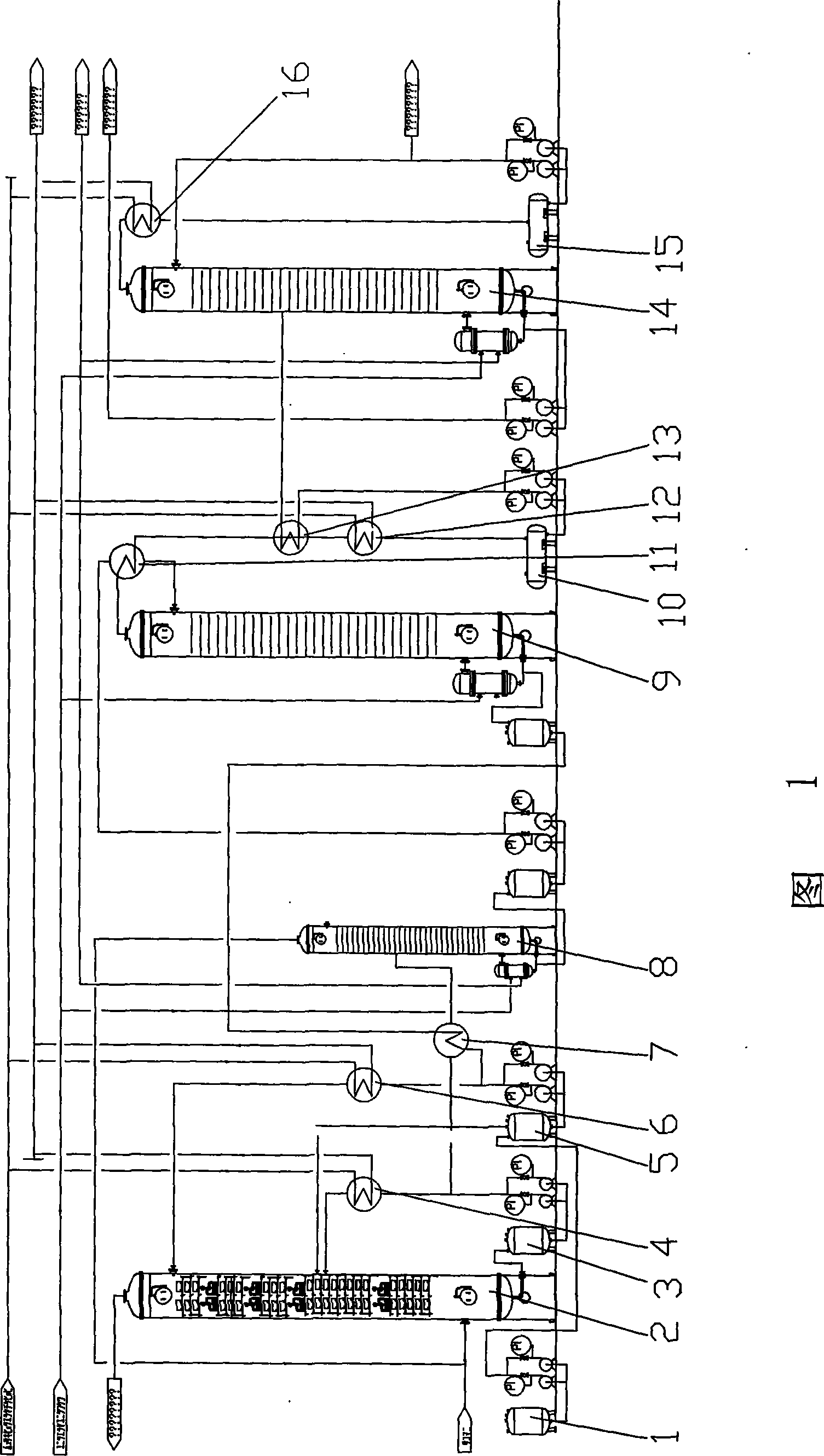

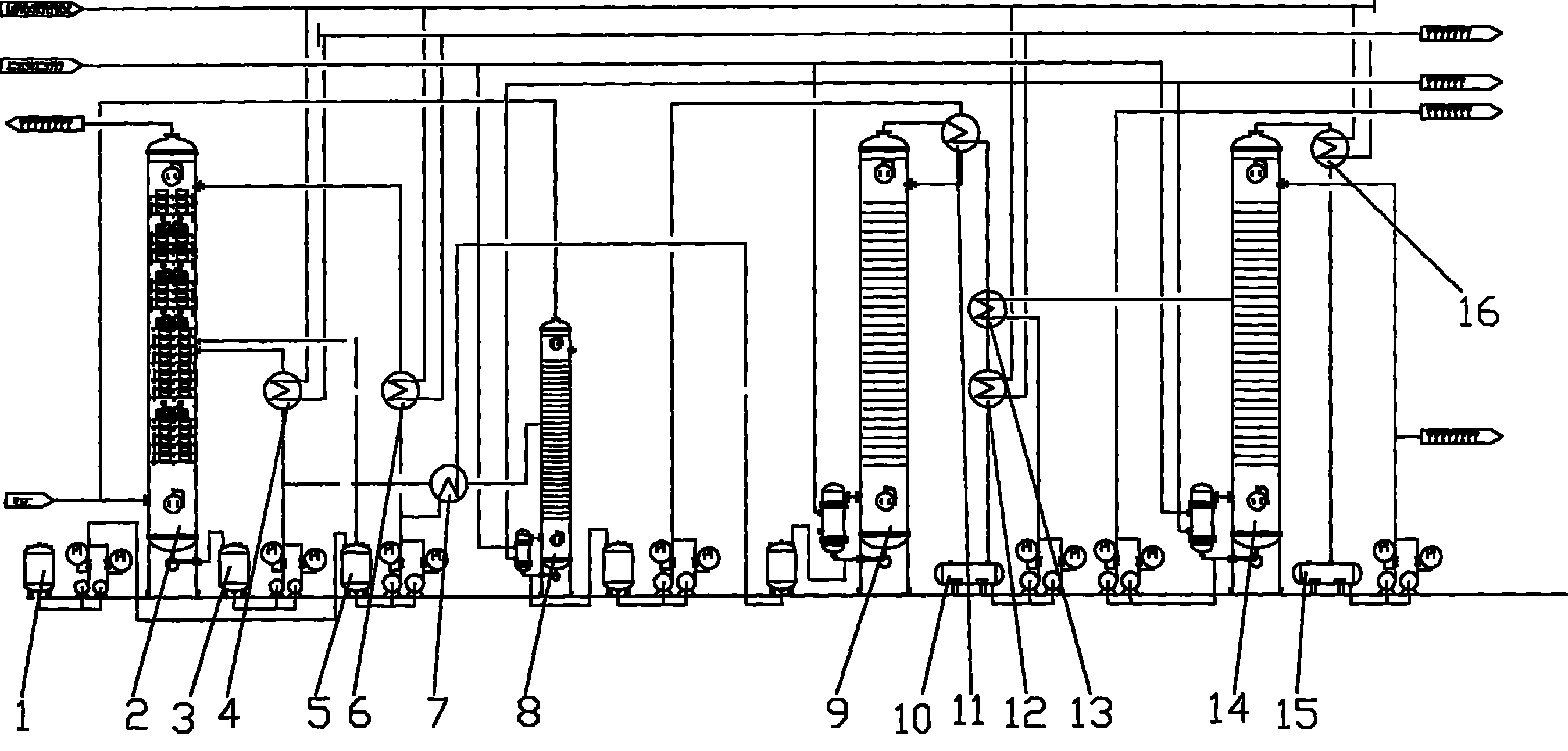

[0015] The ammonia recovery system of the present invention includes an ammonia absorption process, a decyanation process, a desorption process and a rectification process. Its specific equipment includes: phosphoric acid storage tank 1, absorption tower 2, upper tower cooler 6, lower tower cooler 4, buffer tanks 3, 5, decyanation tower 8, lean-rich liquid heat exchanger 7, desorption tower 9, desorption Tower feed preheater 11, desorption tower top condenser 12, dilute ammonia water storage tank 10, rectification tower 14, rectification tower raw material preheater 13, rectification tower top condenser 16, liquid ammonia storage tank 15, steam system and circulating water system.

[0016] Process flow of the present invention:

[0017] (1) Ammonia absorption process: the mixed gas of hydrogen cyanide at about 220°C from the hydrocyanic acid synthesis reactor first enters the bottom of the ammonia absorption tower 2, and is carried out with the ammonium phosphate solution (ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com