Automatic production equipment for plastic toys

A technology for production equipment and toys, which is applied in the field of automatic production equipment for plastic toys, can solve the problems of difficulty in feeding materials, accumulation in place, requiring staff to remove them in time, affecting production work, etc., and achieves the effect of simple feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

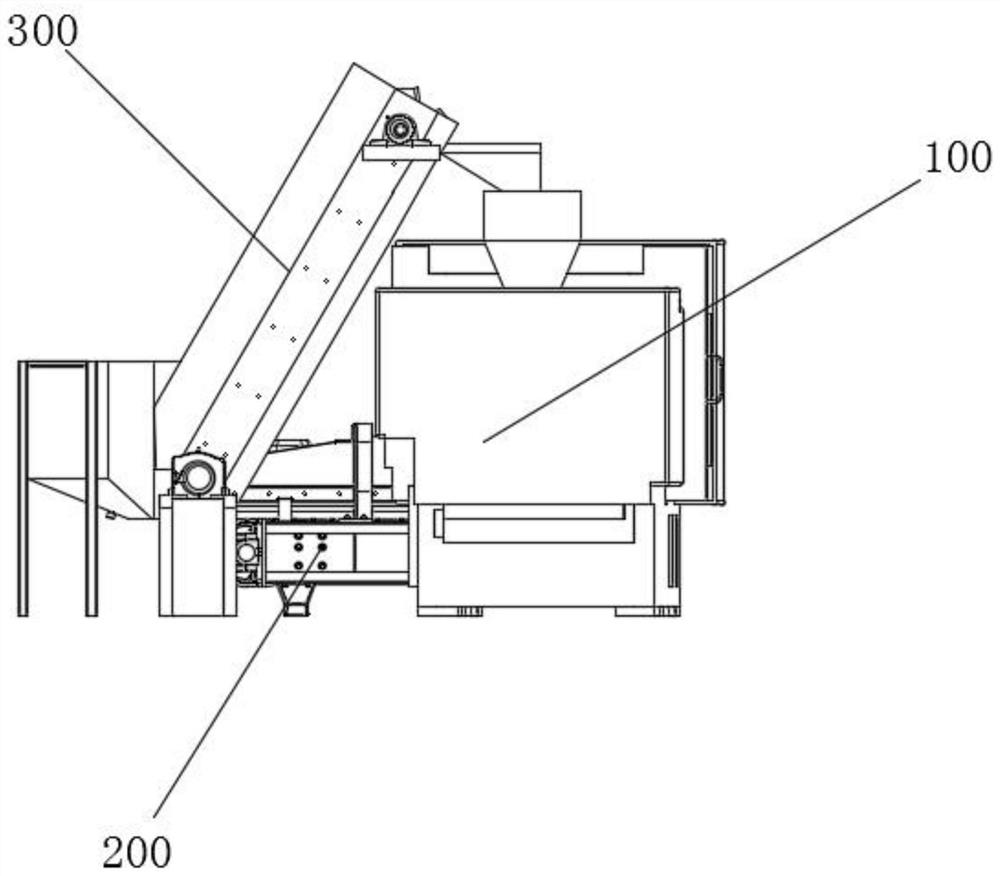

[0035] see Figure 1-8 As shown, the present embodiment is an automatic production equipment for plastic toys, including a molding mechanism 100, a feeding and conveying mechanism 200, and a feeding and conveying mechanism 300. One side of the mechanism 100 is provided with a feeding conveying mechanism 200;

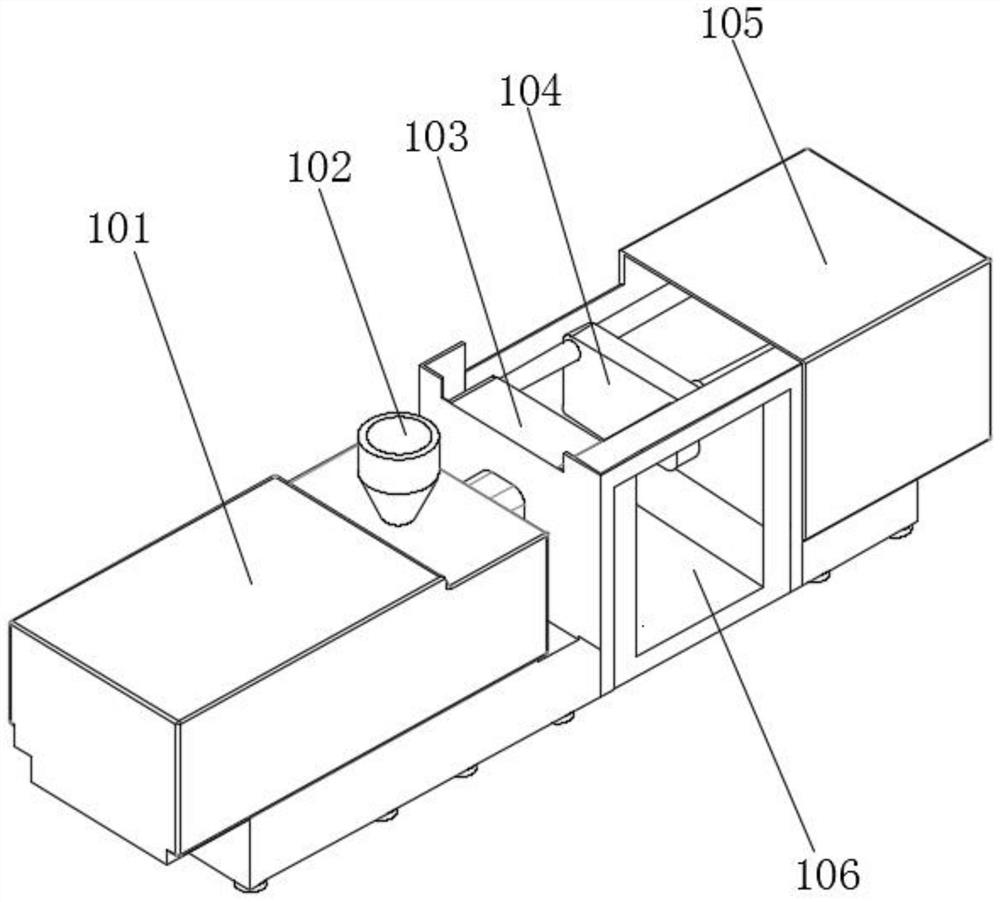

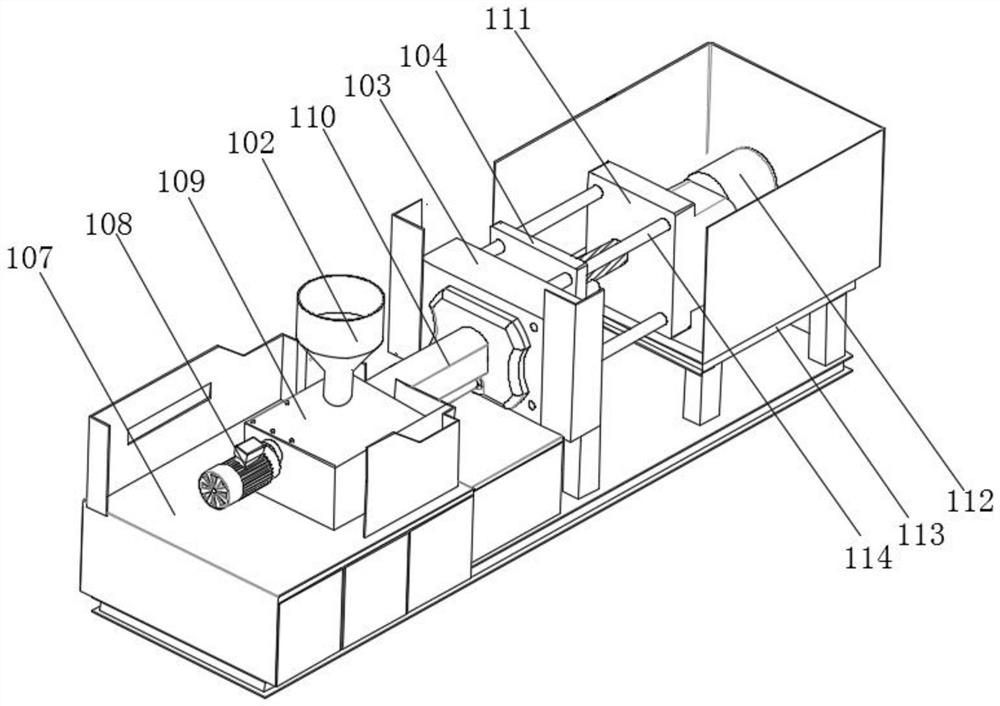

[0036] Wherein, the molding mechanism 100 includes a first installation box 101, a feed hopper 102, an extrusion die head 103, an extrusion shaping die head 104, a second installation box 105, and a connecting box frame 106. The first installation box One end of the top of 101 is equipped with a feed hopper 102, and the end of the first installation box 101 close to the feed hopper 102 is equipped with a connection box frame 106, and the end of the connection box frame 106 away from the first installation box 101 is equipped with a second installation box 105 , the top of the connection box frame 106 inner cavity is equipped with an extrusion molding die 103 and an extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com