Feeding device of vertical net belt combination machine

A composite machine and mesh belt technology, which is applied in the field of composite machines, can solve problems affecting service life, etc., and achieve the effects of improving work efficiency, simplifying the feeding process, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

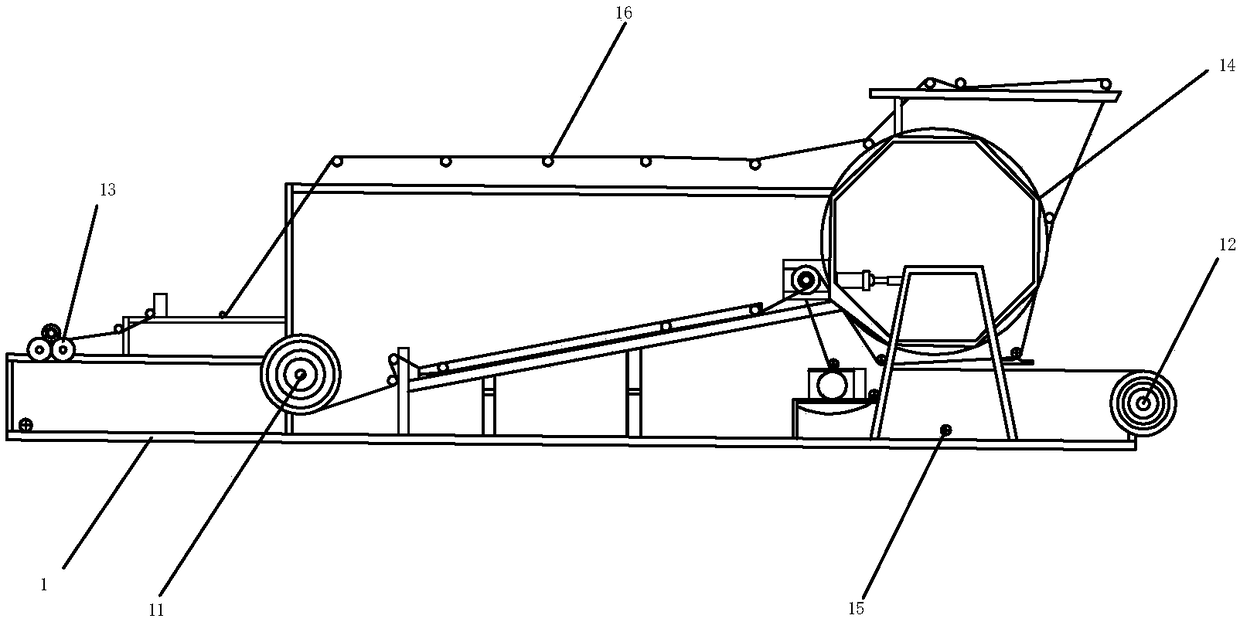

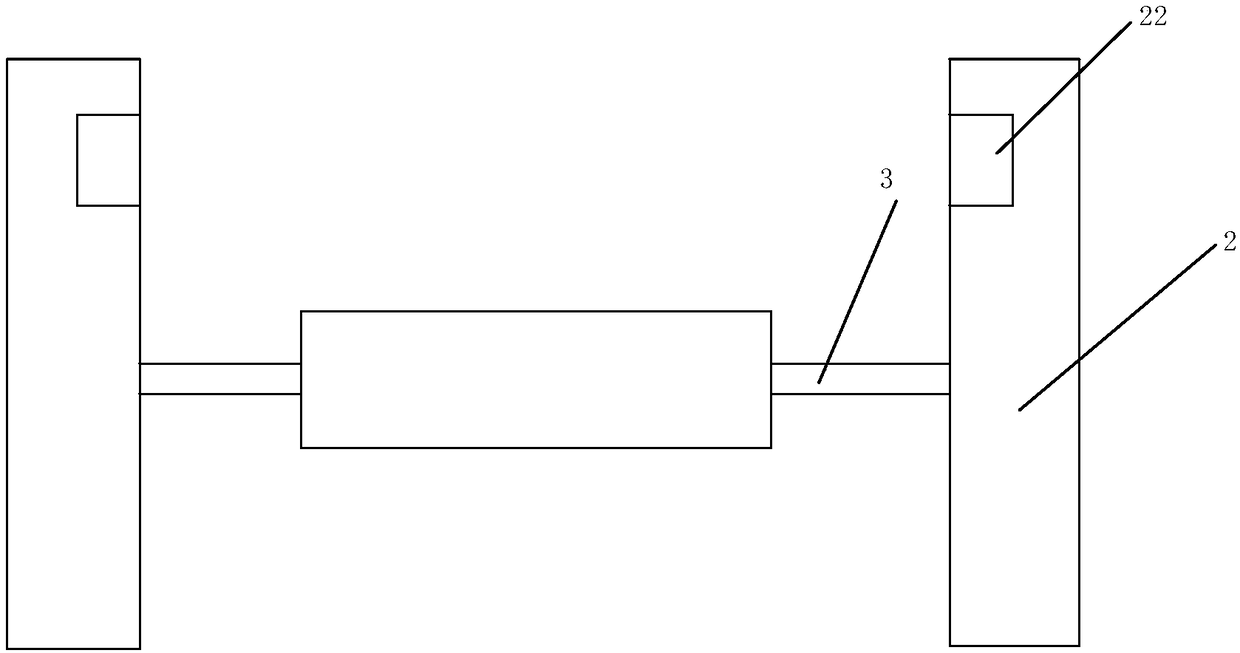

[0029] Embodiment 1: a kind of vertical mesh belt composite machine, such as figure 1 As shown, it includes a frame 1 and a bottom material frame 11 arranged on the frame 1, an upper material frame 12, a finished material frame 13, a drying cylinder 14, a power transmission mechanism 15, and a traction mechanism 16 composed of a plurality of pressing rollers. , wherein the upper material rack 12 and the bottom material rack 11 both include a fixed material rack 2 fixedly connected to both ends of the frame 1 and a detachable material rack 3 for cloth suiting, each fixed material rack 2 is provided with a storage tank 21 , and a gap 22 communicating with the storage tank 21 is provided in the fixed material rack 2 , and the detachable material rack 3 can be placed in the storage tank 21 through the gap 22 and between the two fixed material racks 2 .

[0030] The power transmission mechanism 15 of the vertical mesh belt compound machine is mainly driven by the speed regulating m...

Embodiment 2

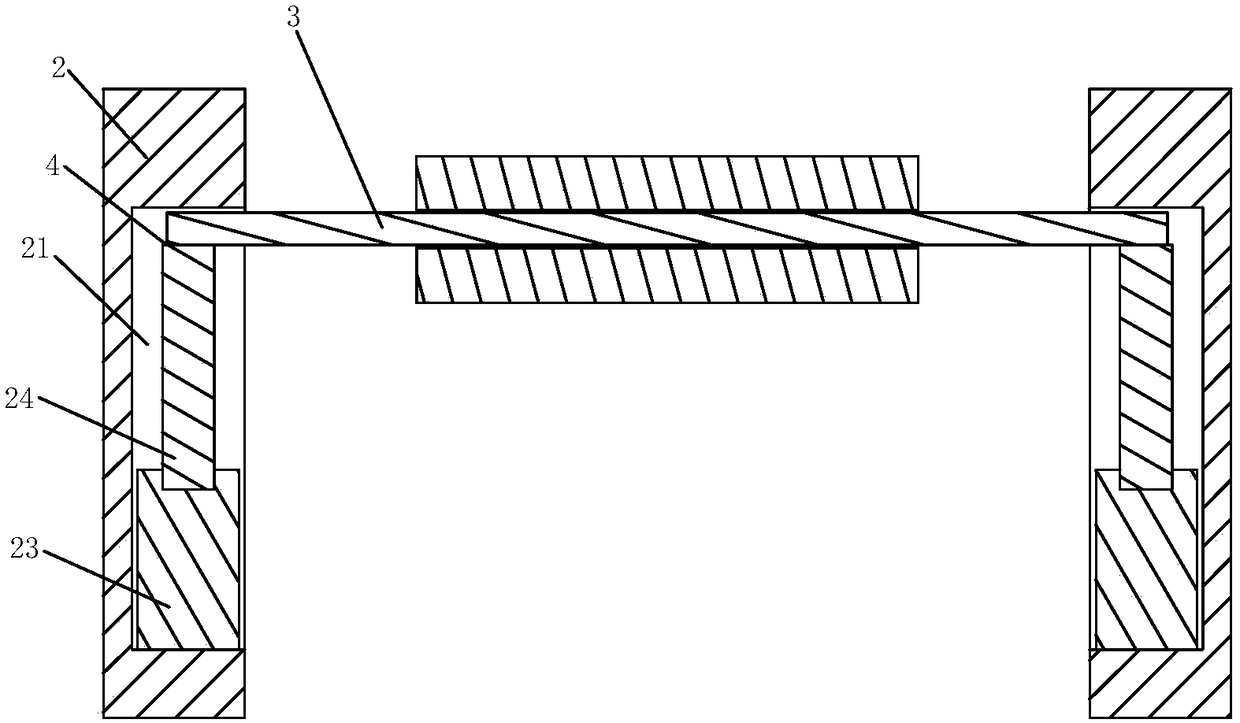

[0033]Embodiment 2: a kind of vertical mesh belt compound machine, the difference with embodiment 1 is, as Figure 4 and 5 As shown, when the detachable material rack 3 is mounted on the two telescopic rods 24, the drive cylinder 23 drives the telescopic rod 24 to descend, in order to avoid the detachable material rack 3 from colliding with the fixed material rack 2 during the descent process. Friction occurs on the inner wall, so the diameter of the detachable material rack 3 is slightly smaller than the diameter of the telescopic rod 24; since the diameter of the detachable material rack 3 is slightly smaller than the diameter of the telescopic rod 24, it can be detached when the vertical mesh belt compound machine is working. The material rack 3 may shake on the two telescopic rods 24. In order to make the installation of the detachable material rack 3 between the fixed material racks 2 more stable, a positioning groove 26 is provided on the upper surface of the telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com