Intelligent feeding device suitable for roll shaft bearing machining and application method of intelligent feeding device

A bearing processing and roller shaft technology, applied in the field of intelligent loading device, can solve problems such as cumbersome loading operations, rising production costs, and difficulty in guaranteeing product quality, and achieve the effects of low production costs, improved pass rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

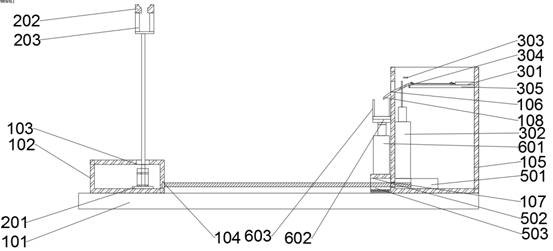

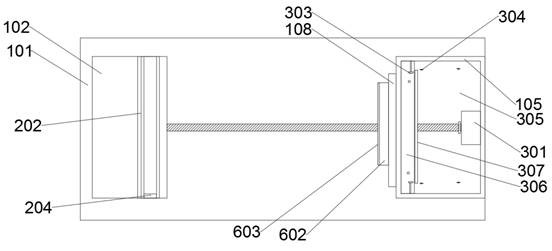

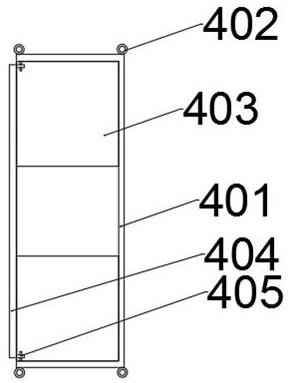

[0056] Embodiment 1, with reference to attached Figure 1-3 , an intelligent loading device suitable for the processing of roller bearings, comprising a main frame, a processing bracket part, a loading part and an intelligent control part.

[0057] The main body frame includes a base 101 , a work bench seat 102 and a material storage seat 105 .

[0058] The base 101 is a rectangular parallelepiped hollow container; a workbench 102 and a storage seat 105 are arranged above the base 101 .

[0059] The workbench 102 is a cuboid hollow container 2, a rectangular through hole 1 103 is set on the upper base of the cuboid hollow container 2; a circular groove 1 104 is set on the right side plate of the cuboid hollow container 2.

[0060] Described storage seat 105 is a rectangular container one, and the left side plate of rectangular container one is provided with a rectangular through hole two 106 and circular through hole one 107; A slideway 108 is set on the rectangular through hol...

Embodiment 2

[0114] Embodiment 2, on the basis of Embodiment 1, two "L" shaped protective shells are added on the base 101, and the two "L" shaped protective shells are inverted and symmetrically arranged, and the screw and the movable seat 502 of the screw motor two are located in the " Below the L”-shaped protective shell. It can effectively protect the screw motor 2, play the role of dustproof and anti-collision, and prolong the service life of the screw motor 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com