Blade ice removing equipment and blade ice removing method applied to wind generating set

A technology for wind turbines and blades, which is applied to wind turbines, wind power generation, mechanical equipment, etc., can solve the problems of reducing the utilization rate of wind turbines, falling off ice, shortening the service life of components, etc., and achieves high deicing efficiency and uniform heating. , the effect of low heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings, in which the same reference numerals are used to denote the same components.

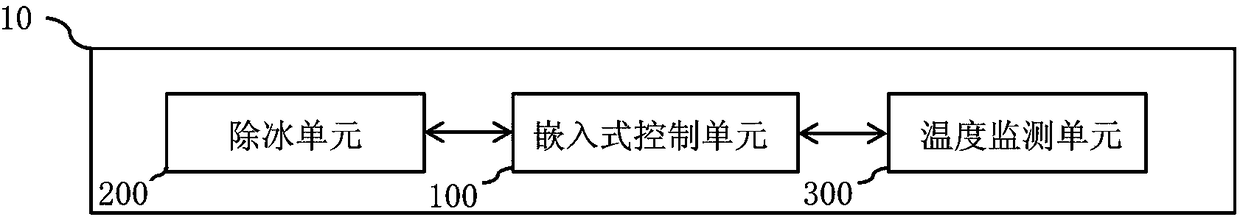

[0027] figure 1 is a block diagram of a blade deicing device 10 for a wind power plant according to an exemplary embodiment of the present invention. Such as figure 1 As shown in , the blade deicing device 10 includes a deicing unit 200 , an embedded control unit 100 and a temperature detection unit 300 .

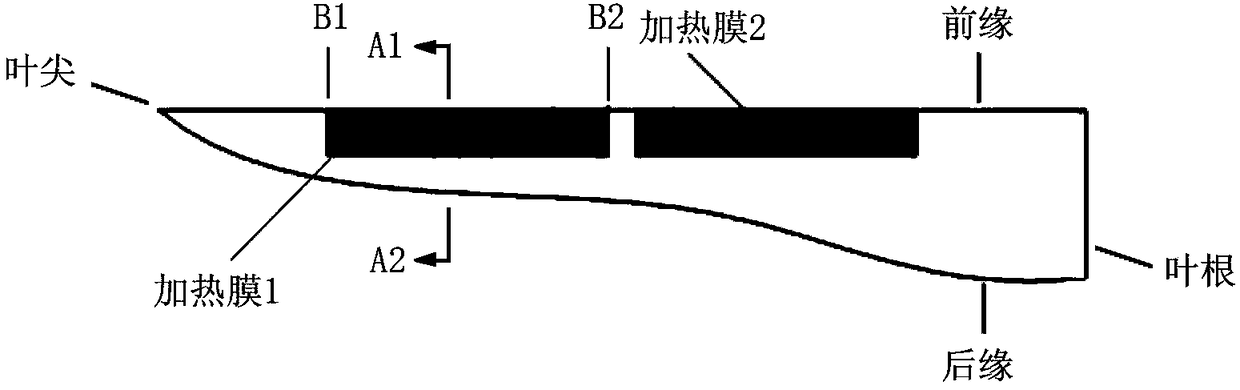

[0028] The deicing unit 200 is used for deicing the blade. Specifically, in the case that the wind power generating set includes N blades, the deicing unit 200 includes 2M heating films laid on each blade of the wind generating set, that is, the deicing unit 200 includes a total of 2M×N blocks The heating film, wherein, M is an integer greater than or equal to 1, and N is an integer greater than or equal to 3. For example, when the wind power generator has 3 blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com