Method for fully-automatic on-line sampling of freeze dryer

A fully automatic, freeze-drying machine technology, used in drying, drying solid materials, drying solid materials without heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

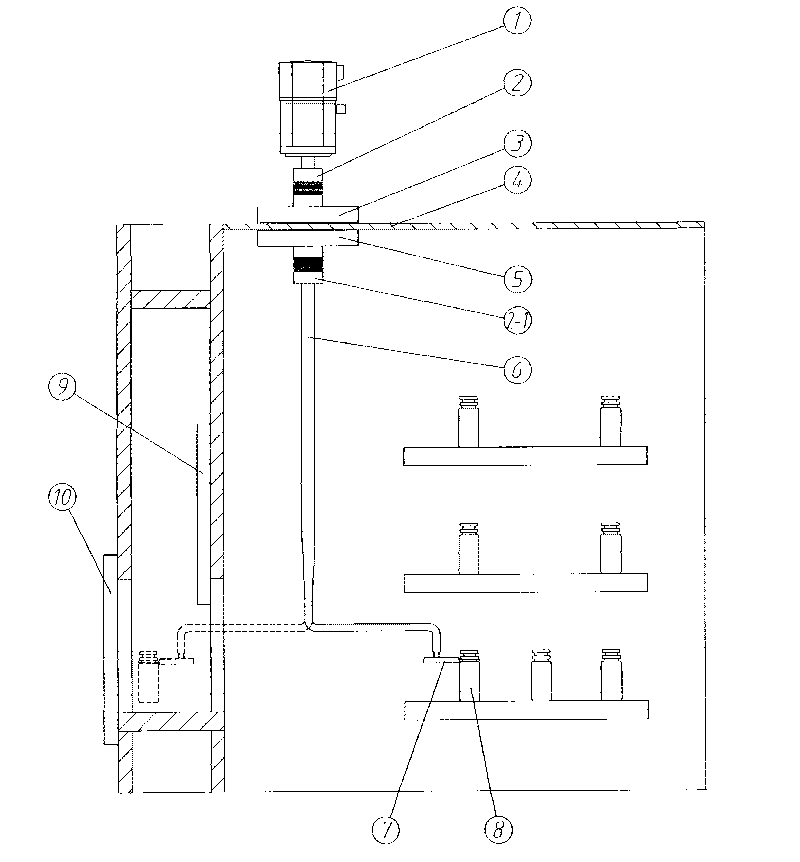

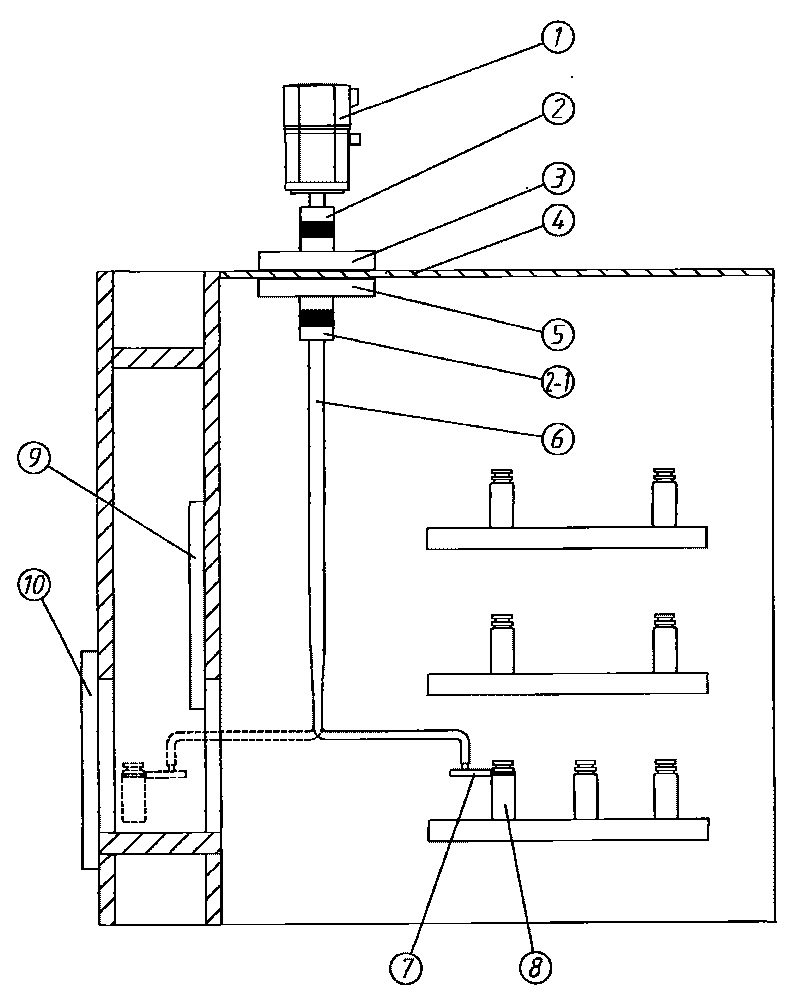

[0007] Below in conjunction with embodiment accompanying drawing, the present invention is further described:

[0008] see attached figure 1 , install the motor (1) that controls the crank (6) on the top of the freeze-drying box (4), use the coupling (2) to connect the motor (1) and the outer drive turntable (3). In order to prevent vacuum leakage, the inner drive turntable (5) Set in the vacuum chamber of the freeze-drying box (4), the inner drive turntable (5) and the outer drive turntable (3) are magnetically coupled, and a rolling bearing is installed in them to reduce the frictional force generated when they rotate. Inside the freeze-drying box (4), the inner drive turntable (5) is also connected with the crank (6) through the coupling (2-1). The manipulator (7) is installed on the front end of the crank (6), so that the motor (1) can be used to drive the manipulator (7) to move.

[0009] see attached figure 1 , the whole process is carried out in a vacuum state. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com