Forming operating mechanism for steel reinforcement cage with protecting layers and method

A forming operation and steel cage technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of consuming manpower and material resources, unreliable spacing between main bars, and complicated position calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

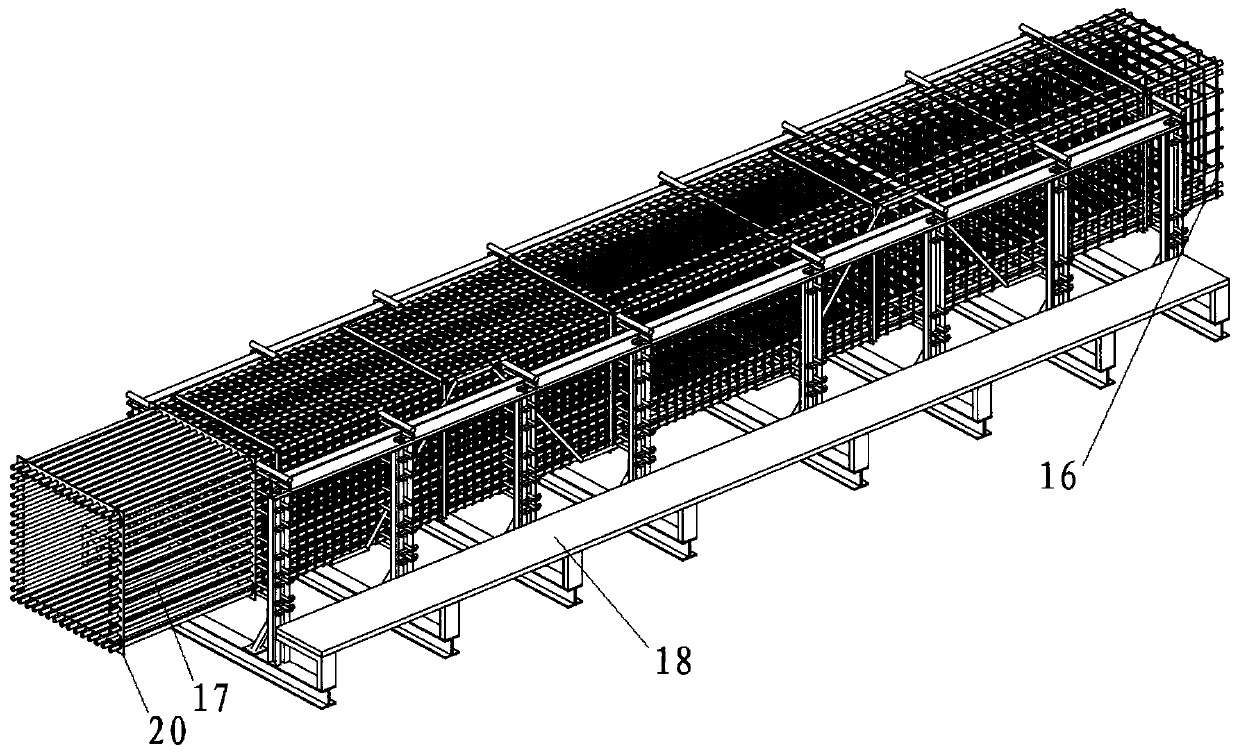

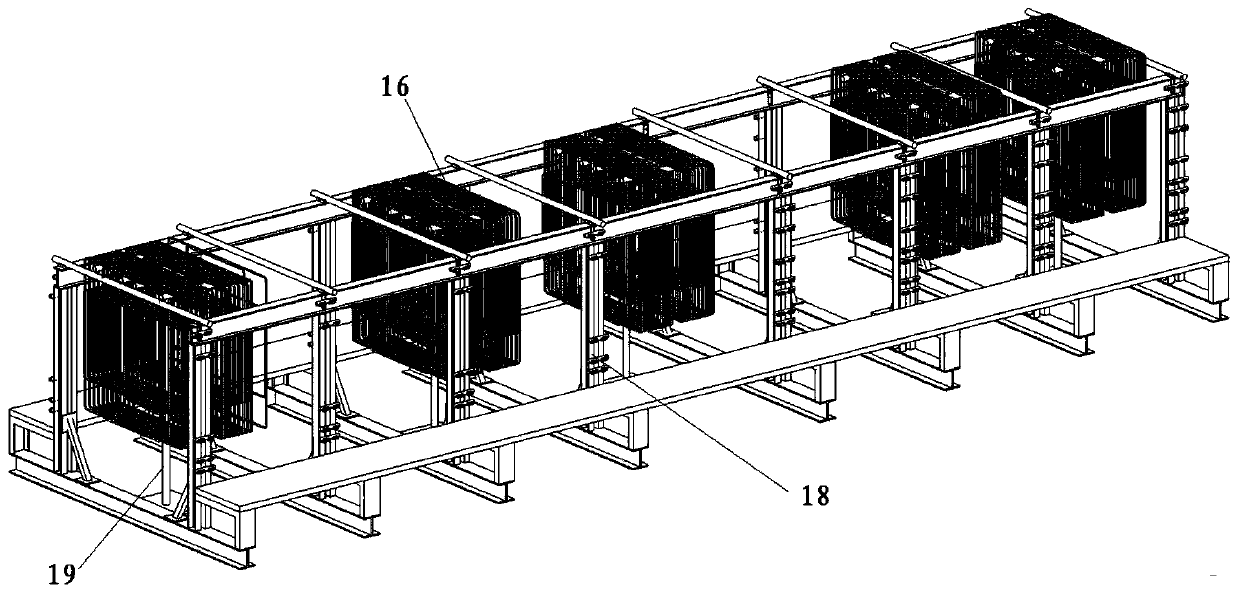

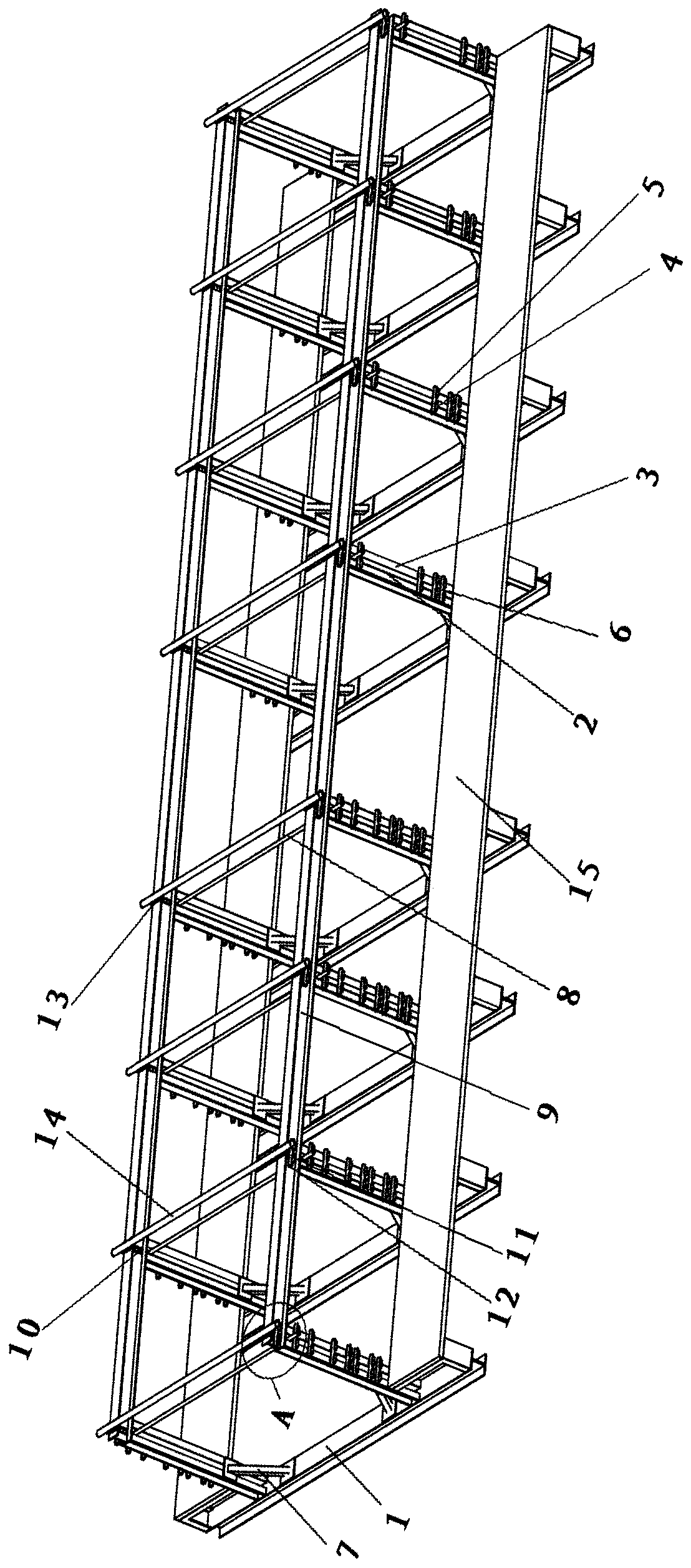

[0068] Such as Figure 1 to Figure 12 As shown, the present invention includes a main reinforcement positioning frame 18 for locating the position of the main reinforcement 17, a plurality of stirrup suspension frames 19 that are all matched with the main reinforcement positioning frame 18 and are used to support the suspension stirrup 16, and a plurality of sleeves along the length direction of the reinforcement cage. The protective layer 20 arranged outside the main reinforcement of the reinforcement cage, the main reinforcement positioning frame 18 includes two top supporting steel beams 9 arranged in parallel, and a plurality of top supporting steel beams 9 along the length direction of the top supporting steel beams 9 are arranged in parallel on the top of the two top supporting steel beams 9. The steel cage load-bearing bar 14 and a plurality of support positioning mechanisms arranged in parallel at the bottom of the two top support steel beams 9 along the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com