Wood product raw material machining device

A technology for processing equipment and wood products, which is applied to wood processing utensils, manufacturing tools, bark, etc., can solve the problems of increasing processing procedures, different thicknesses of logs to be peeled, and low efficiency, and achieves the effect of avoiding mechanical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

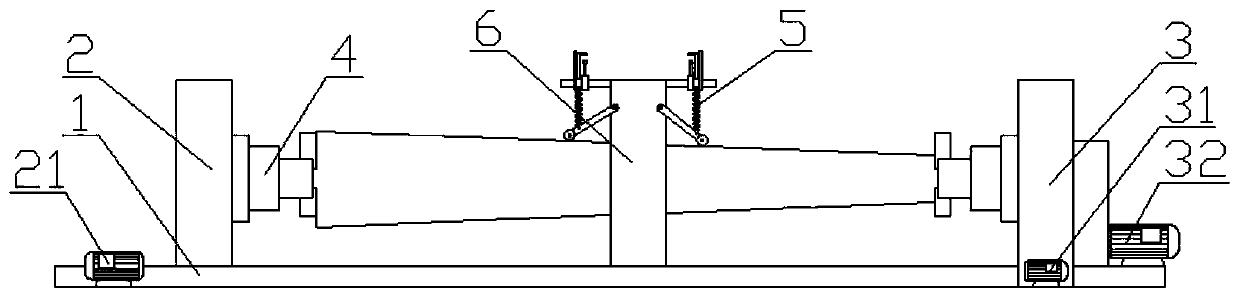

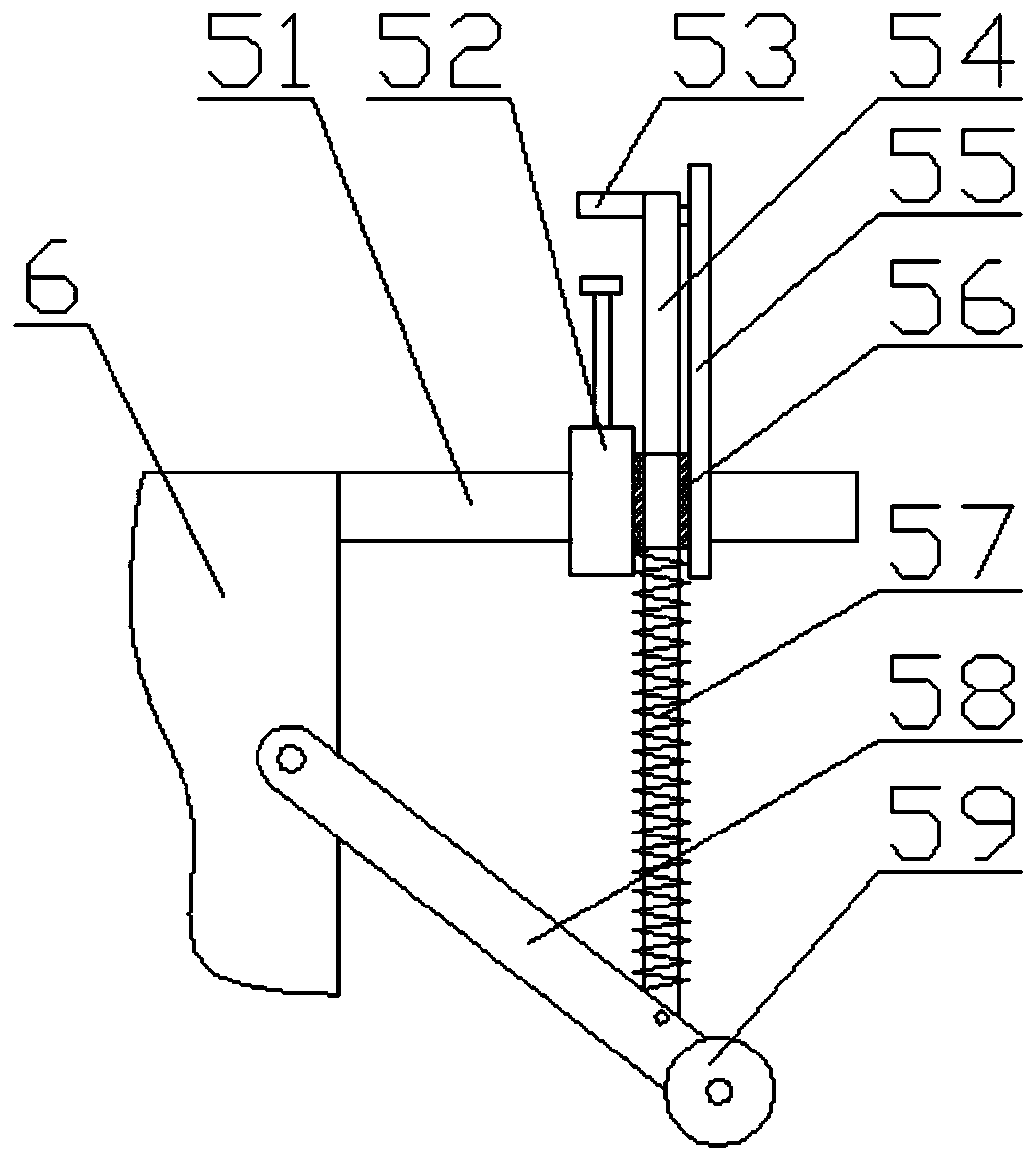

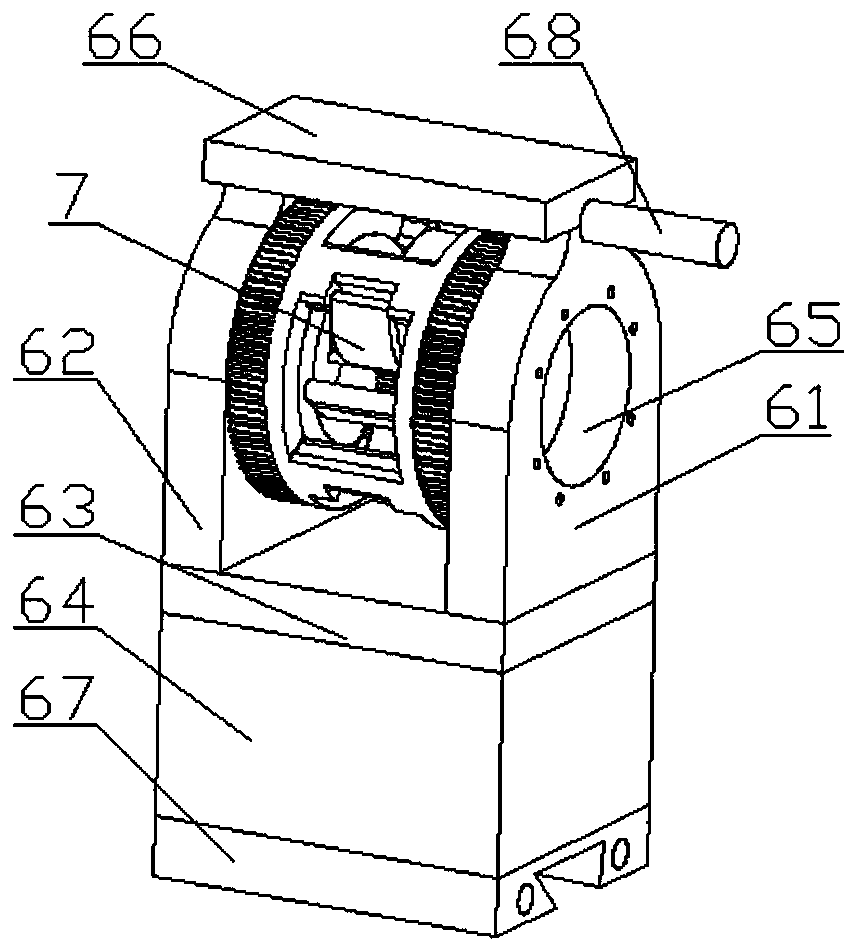

[0028] Such as Figure 1 to Figure 7 Shown; A wood product raw material processing device includes a base plate 1, and the base plate 1 is provided with a slide rail, a peeling screw, a moving motor 21, a fixed base 3 and a peeling moving motor 31, and the slide rail A moving base 2 and a peeling mechanism 6 are arranged on the top, a power screw is connected to the power rod of the mobile motor 21, and one end of the power screw runs through the moving base 2, and the moving base 2 and the fixed base 3 Claws 4 are arranged on the top, the peeling mechanism 6 is located between the moving base 2 and the fixed base 3, one end of the peeling screw rod is connected to the peeling mobile motor 31 power rod, the peeling wire The other end of the rod runs through the peeling mechanism 6, and the fixed base 3 is provided with a rotating motor 32, and the rotating motor 32 is connected with the claw 4 on the fixed base 3, and the peeling mechanism 6 both sides are provided with Diame...

Embodiment 2

[0032] On the basis of Embodiment 1, the adjustment ring 71 is provided with two guide teeth 72, and the two guide teeth 72 are located at both ends of the adjustment ring 71; the peeling plate 79 is arc-shaped; The arc diameter of the peeling plate 79 is greater than or equal to the diameter of the fixed ring 74; the diameter of the fixed ring 74 is greater than the diameter of the through hole 65; the blade 710 forms an angle A with the horizontal line, and the degree of the angle A is from 1 degree to 20 degrees; the lifting plate 63 is provided with a triangular material guide plate, and the triangular material guide plate is located below the adjustment ring 71; at least 3 peeling devices 75 are hinged between the adjustment ring 71 and the two fixed rings 74 ; At least two diameter detection devices 5 are provided on one side of the peeling mechanism 6 provided with the diameter detection device 5 .

[0033] By setting a guide tooth 72 at both ends of the adjustment ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com