A dynamic counterweight balancing system and balancing method for UAV stabilization

A counterweight balance and unmanned aerial vehicle technology, which is applied in the direction of aircraft stability, electromechanical devices, and electric components of gravity-operated devices, and can solve problems such as time-consuming, unmanned aerial vehicle impact, and turbulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

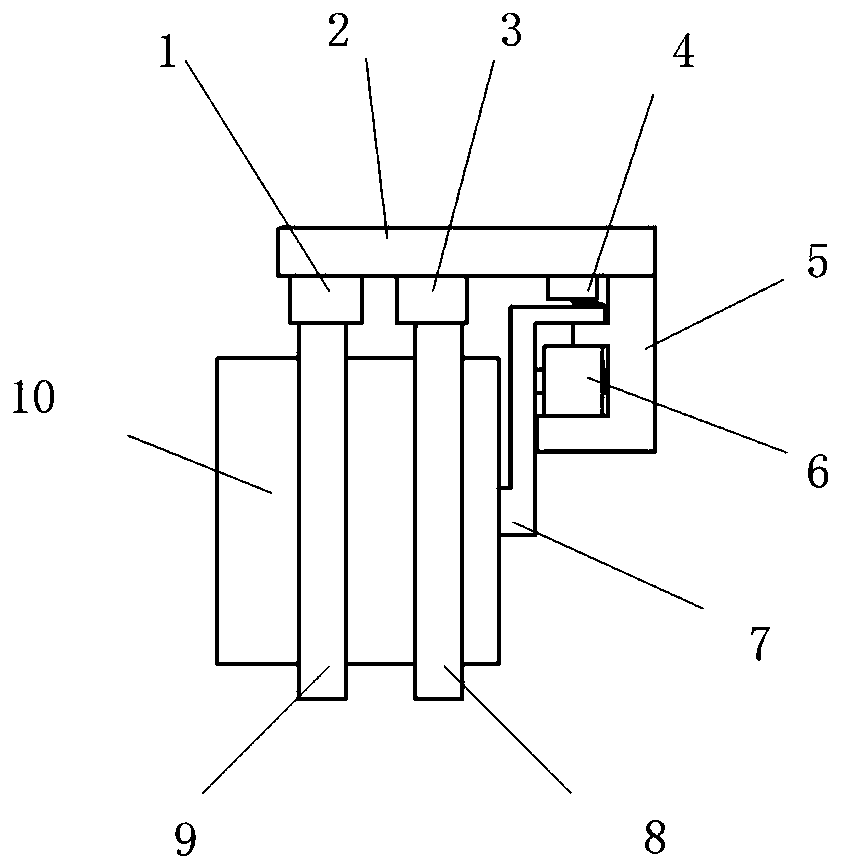

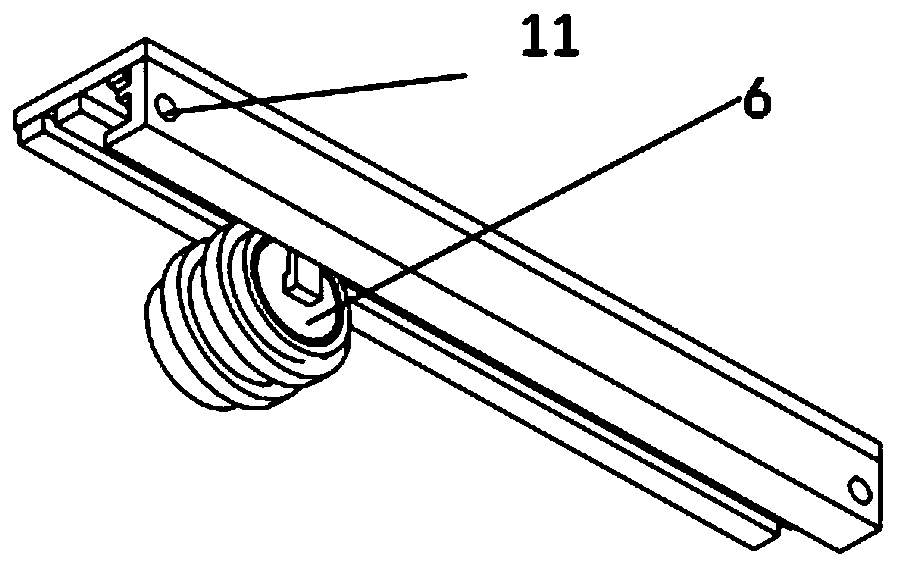

[0037] Such as figure 1 As shown, the dynamic control counterweight balance system of the UAV stabilization of the present embodiment includes: fixed frame 2, positive pole conductive rack 1, negative pole conductive rack 3, first and second metal gear rings 8 and 9, miniature DC motor, counterweight motor sleeve 10, sliding resistance sheet 4, sliding resistance contact, connecting rod 7, guide rail groove 5, rolling sleeve 6, limit device 11 and control circuit; wherein, the micro DC motor is arranged on the counterweight In the motor sleeve 10, the rotating shaft of the micro DC motor coincides with the central axis of the counterweight motor sleeve 10, and the outer wall of the micro DC motor and the inner wall of the counterweight motor sleeve 10 are not in contact with each other, and the counterweight motor sleeve 10 is insulated. material, the rotating shaft of the micro DC motor is fixed on the center of the bottom wall of the counterweight motor sleeve 10; the first ...

Embodiment 2

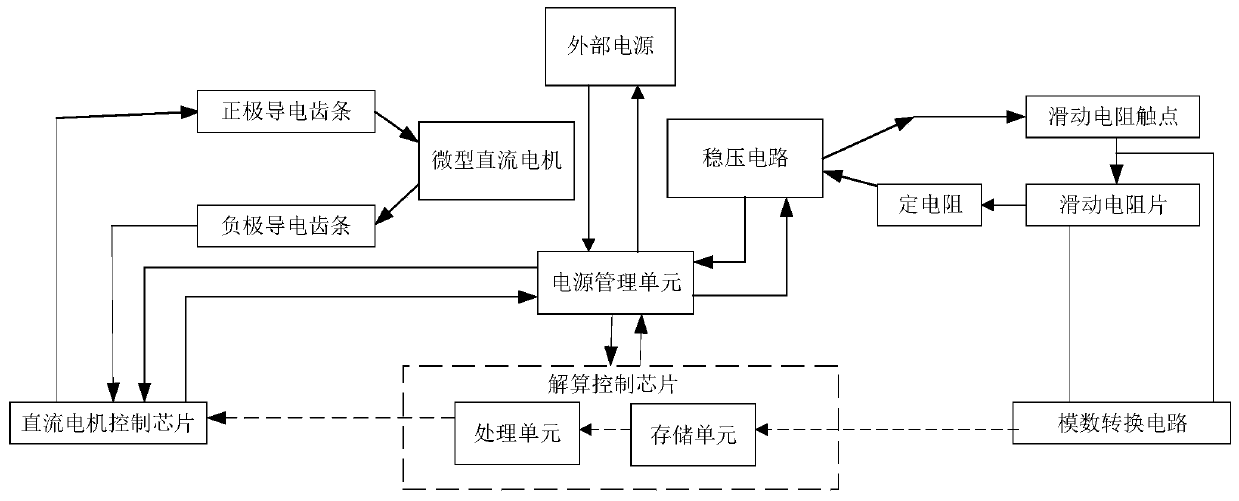

[0052] Fixed frame, positive conductive rack, negative conductive rack, first and second metal gear rings, micro DC motor, counterweight motor sleeve, sliding resistance sheet, sliding resistance contact, connecting rod, guide rail groove and rolling sleeve form the mechanical part.

[0053] Such as Figure 5 As shown, in this embodiment, the two directions are registered, and two sets of mechanical parts A in the front and rear directions are installed in parallel along the front and rear directions of the drone. The positive and negative conductive racks of the two sets of mechanical parts in the front and rear directions are parallel to each other. The installation is symmetrical about the connection line between the front and rear; a set of left and right mechanical parts B is installed on the connection between the two sets of front and rear mechanical parts located on the left and right. The mechanical parts in the left-right direction and the mechanical parts in the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com