Bagged material multi-channel parallel delivery method and bagged material multi-channel parallel delivery mechanism

A multi-channel, conveying mechanism technology, applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve the problems of low transmission efficiency, impact on packaging, high operating costs, etc., achieve low processing and manufacturing costs, convenient installation and maintenance, and improve The effect of total efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

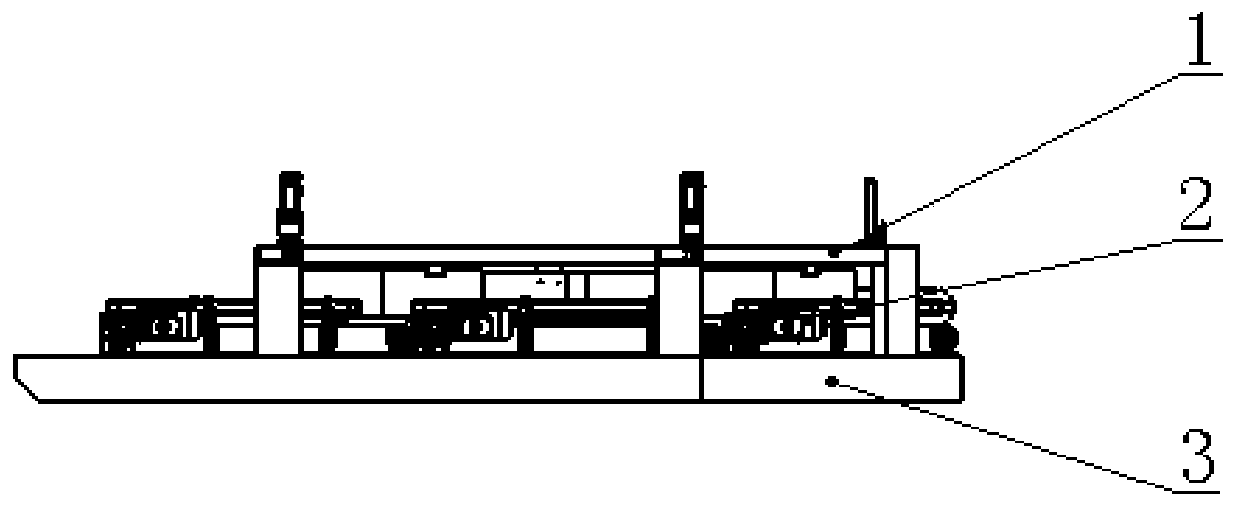

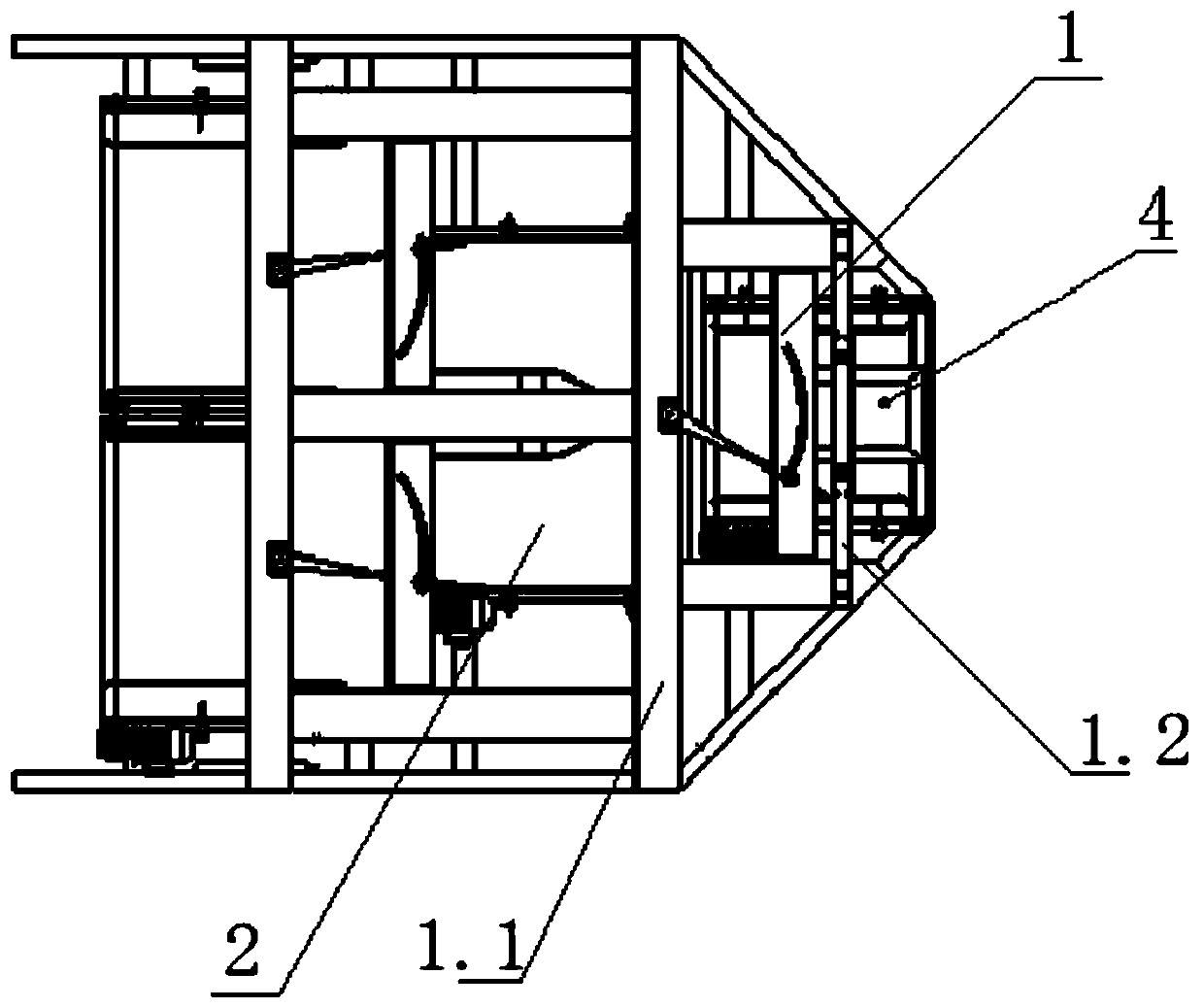

[0039] see Figure 1-10 , the present invention relates to a multi-channel parallel delivery method for bagged materials. The method is as follows: when the bagged materials are transported to the multi-channel parallel delivery mechanism through the previous mechanism, the bagged materials entering the delivery mechanism are intermittently delivered by the blocking mechanism. The bagged material that completely passes through the blocking mechanism is driven by the conveying mechanism and enters the bagged material reversing mechanism. Dispatch to multiple channels and output from the corresponding outlets; the delivery mechanism moves reciprocally according to the required order, so as to finally achieve the purpose of multi-channel and parallel conveying of bagged materials;

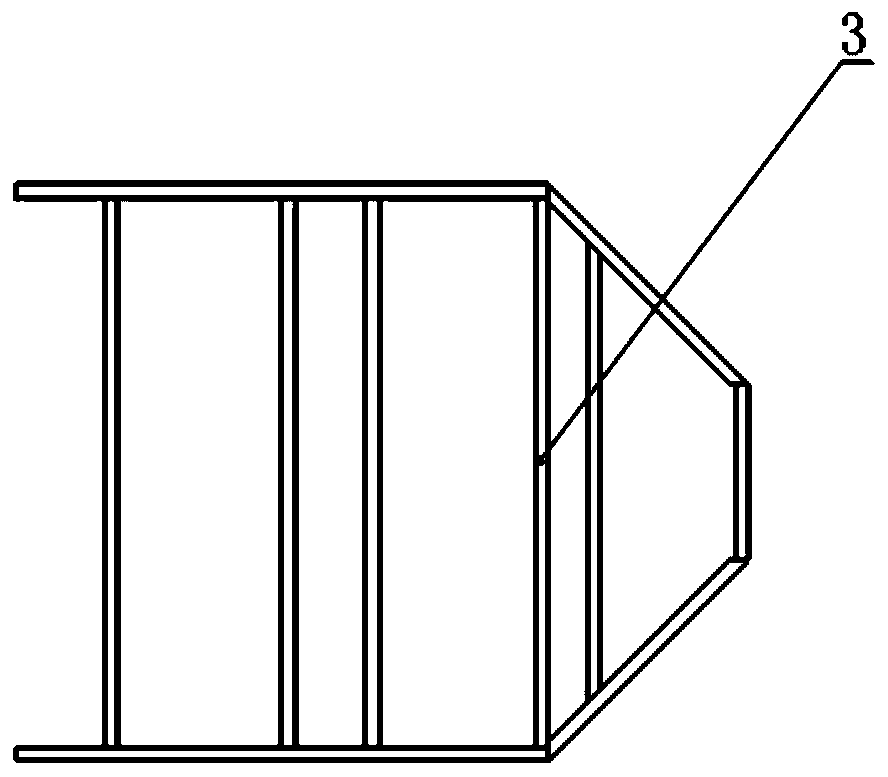

[0040]The delivery method of the above-mentioned multi-channel parallel delivery mechanism for bagged materials is realized based on a multi-channel parallel delivery mechanism. The multi-channel para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com