Gear pump safety valve structure

A safety valve and gear pump technology, applied in lift valves, engine components, mechanical equipment, etc., can solve the problems of poor manufacturability, high requirements on cone surface accuracy, and difficulty in precise and stable pressure regulation, and achieve accurate pressure regulation and stable pressure relief. Fast, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

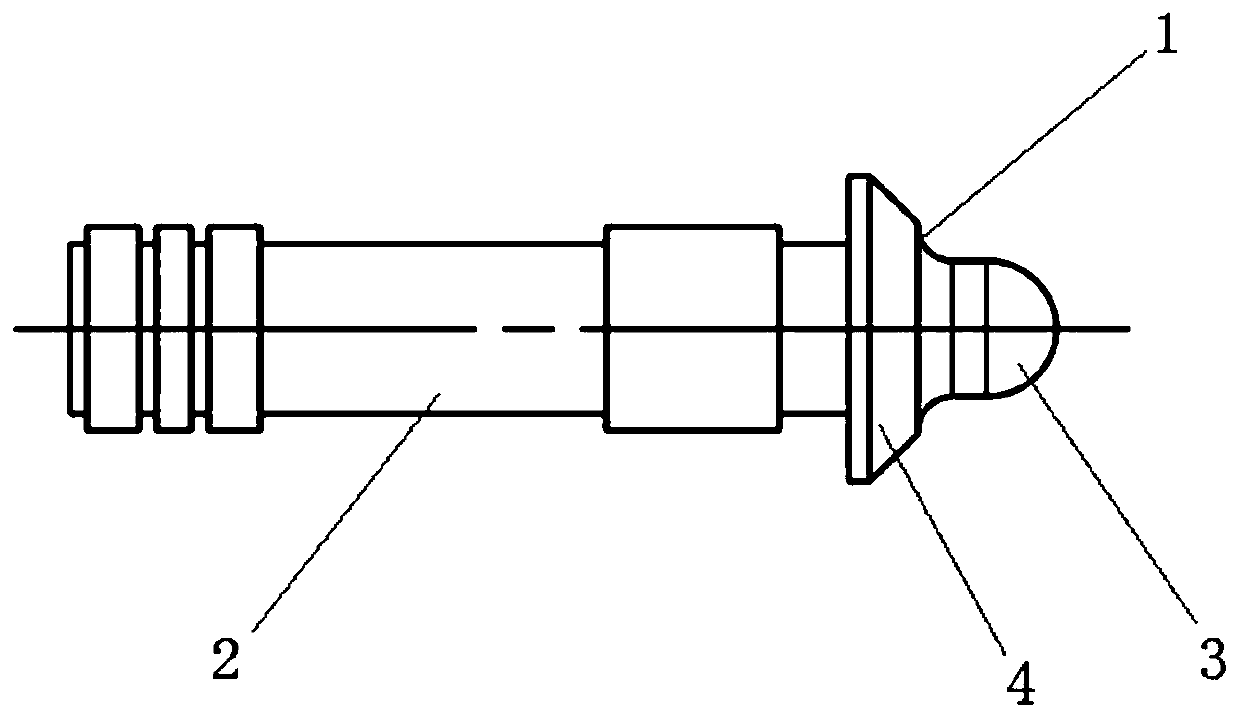

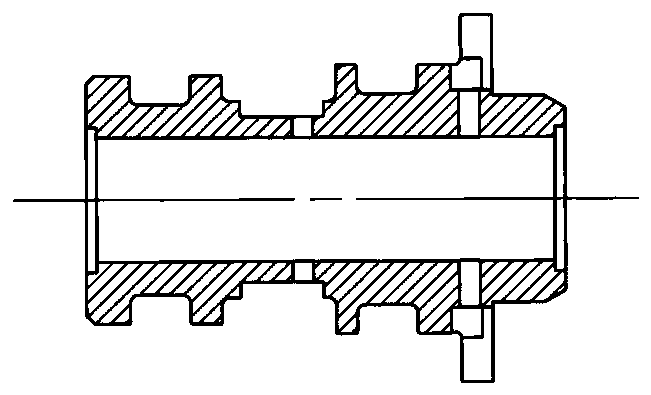

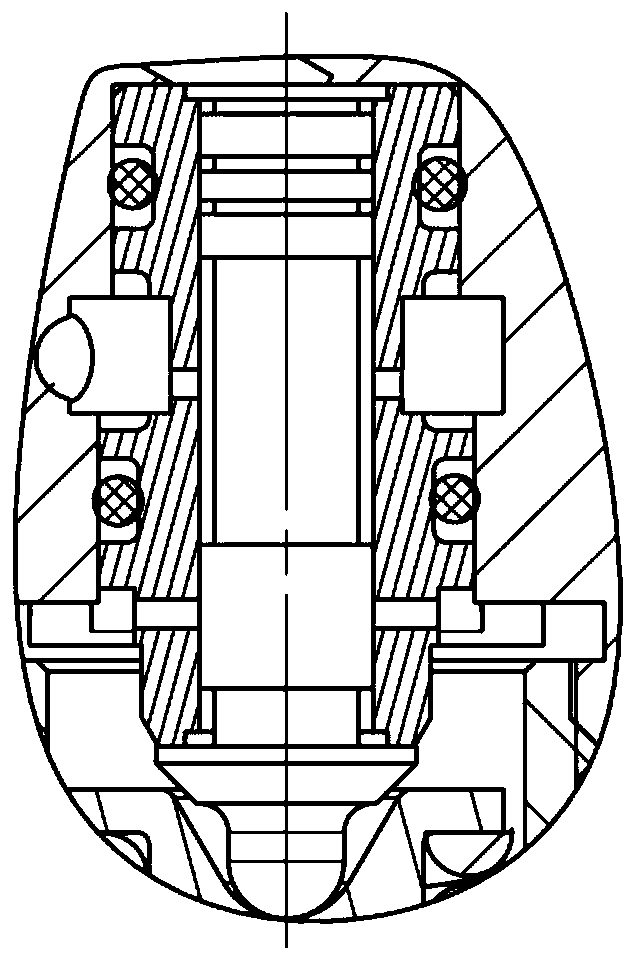

[0016] Such as figure 1 , a gear pump safety valve structure, the safety valve structure includes a valve core and a valve sleeve, the valve core is a rotary body structure, the front part of the valve core is a working part, the rear part of the valve core is rod-shaped, and the shape of the front part of the valve core is It is a combination of a round table and a round convex head, the outer diameter of the round convex head is smaller than the radius of the upper table of the round table, the transition between the tail of the round convex head and the upper table of the round table is an arc transition, and the head of the round convex head has a hemispherical shape;

[0017] The rear part of the valve core is arranged in the valve sleeve and is slidingly fitted with the valve sleeve, the front part of the valve core is located outside the valve sleeve, and the radius of the lower surface of the circular platform is larger than the inner diameter of the valve sleeve;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com