A method for measuring the output torque of a harmonic reducer flex wheel

A technology of harmonic reducer and output torque, applied in force/torque/work measuring instruments, measuring devices, torque measurement and other directions, which can solve the difficulty of accurately obtaining joint end torque, inaccurate indirect measurement, and complex joint force process, etc. problem, to achieve the effect of direct measurement and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

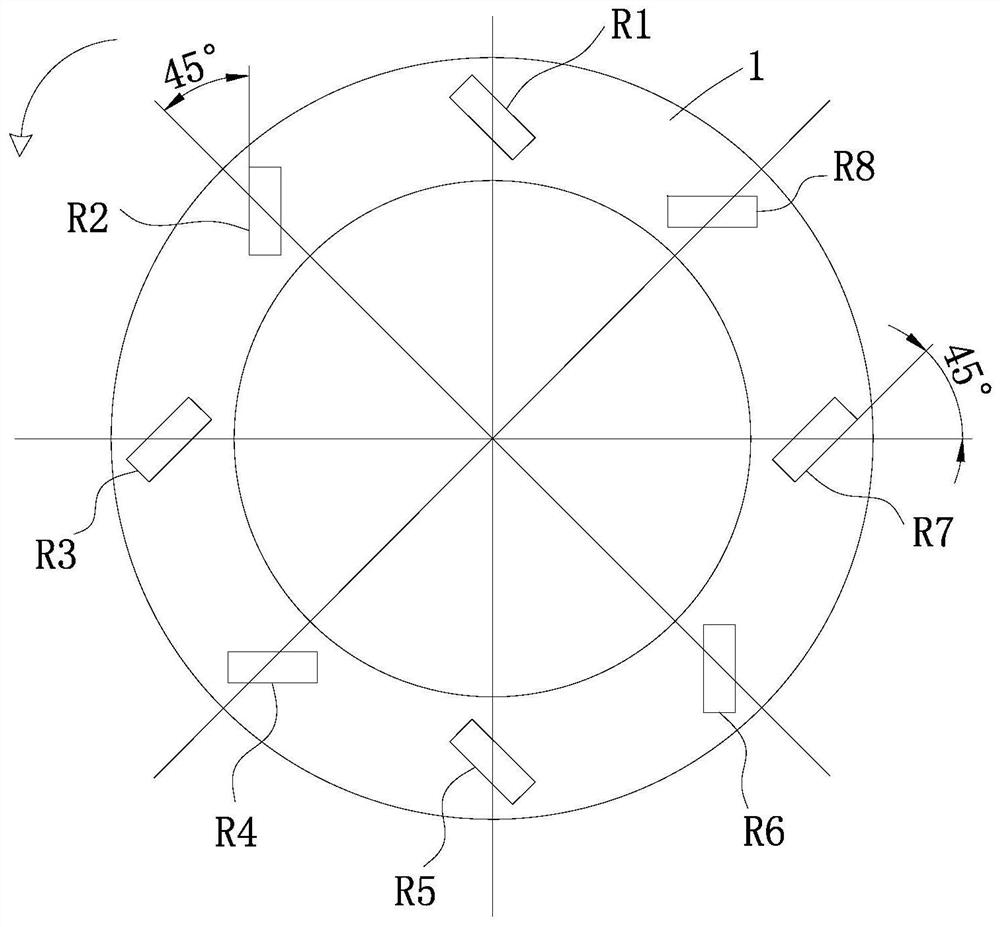

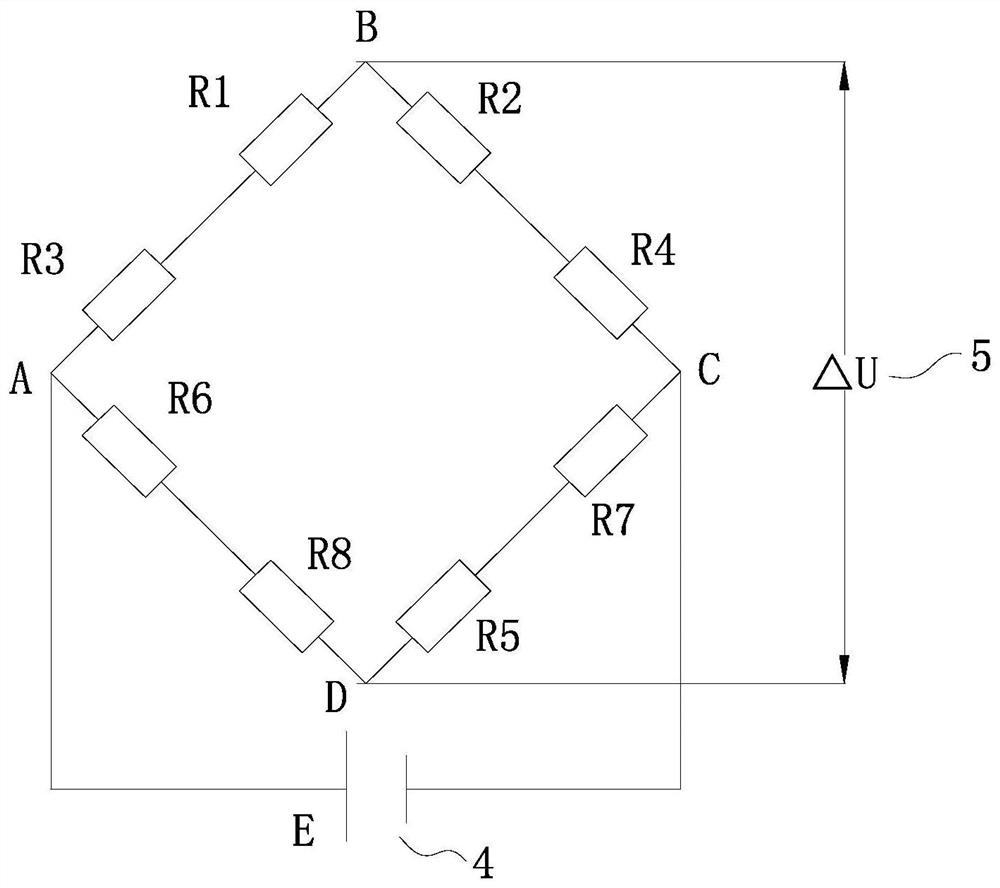

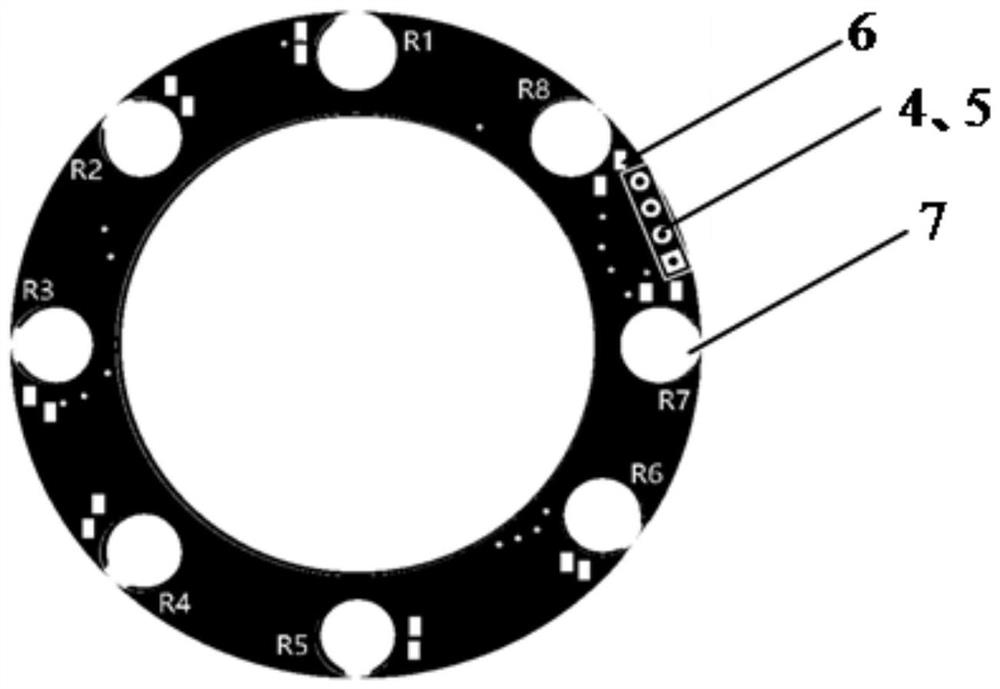

[0036] exist figure 1 Contains the harmonic reducer flexible spline 1 and the strain gauge; in figure 2 Contains power input terminal 4 and voltage output terminal 5; in image 3 Contains the rubber-based solder joints 6 of the strain gauges and the placement area 7 of the strain gauges. figure 2 The middle power supply input terminal 4 and the voltage output terminal 5 are in image 3 be reflected in.

[0037] Principle: By pasting eight strain gauges on the outer wall 1 of the harmonic reducer flexspline, the torque on the flexspline is directly sensed and measured with the strain gauges. Eight strain gauges with figure 1 The arrangement is pasted on the outer wall of the flexspline 1, and the acute angle between the length direction of the strain gauge and the radial line on the flexspline passing through the center of the strain gauge is 45 degrees, and the leads of the eight strain gauges are welded on the strain gauge On the rubber-based solder joint 6 of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com