High-strength cordierite ceramic honeycomb body and preparation method thereof

A ceramic honeycomb and cordierite technology, which is applied in the field of cordierite ceramic honeycomb and its preparation, can solve the problems of high porosity, high thermal expansion coefficient, isostatic strength, and high thermal shock resistance of cordierite ceramic honeycomb, and achieve thermal expansion Excellent coefficient, high isostatic strength, and high thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] According to an embodiment of the present application, the preparation method of cordierite ceramic honeycomb comprises the following steps:

[0054] 1) Mixing: The prepared raw material composition, pore-forming agent, and binder are dry-mixed in a coulter mixer, and then sprayed into a mixed liquid of lubricant and water for wet mixing;

[0055] 2) Mud training: The ceramic primary mixture after wet mixing is transported to the net mud training machine for mud training;

[0056] 3) Extrusion molding: After the mud is turned into mud, it is transported to a single-screw extruder, twin-screw extruder or hydraulic extruder for molding, and the mud becomes a cylindrical wet billet through a mold;

[0057] 4) Microwave drying: After being cut by a wet billet cutting machine, the honeycomb ceramic cylinder is dried and shaped into a green billet by a microwave dryer;

[0058] 5) Green body cutting: the green body is cut to a specific height by the green body cutting machin...

Embodiment 1

[0061] Example 1 Preparation of cordierite ceramic honeycomb body 1#

[0062] Raw material composition #1 that can be fired into cordierite honeycomb ceramics: 40wt% talc with an average particle size of 16-19μm, 10.8wt% kaolin with an average particle size of 6-7μm, and 6% calcined kaolin with an average particle size of 2-3μm 15.2wt% aluminum oxide with an average particle size of 3-4μm, 15.8wt% aluminum hydroxide with an average particle size of 5-8μm and 12.2wt% silicon oxide with an average particle size of 3-5μm.

[0063] Preparation of cordierite ceramic honeycomb body 1#: mix 100Kg raw material composition 1#, 6Kg hydroxypropyl methylcellulose, 10Kg polyphenylene sulfide, 2Kg tall oil fatty acid and 33Kg water in a coulter, after mixing The ceramic primary mixture is kneaded or smelted to make mud. The mud is conveyed to a twin-screw extruder or hydraulic extruder for molding, and the mud passes through a mold to become a cylindrical wet billet. After the wet blank c...

Embodiment 2

[0064] Example 2 Preparation and performance test of cordierite ceramic honeycomb body 2#-8# and comparison cordierite ceramic honeycomb body D1#-D9#

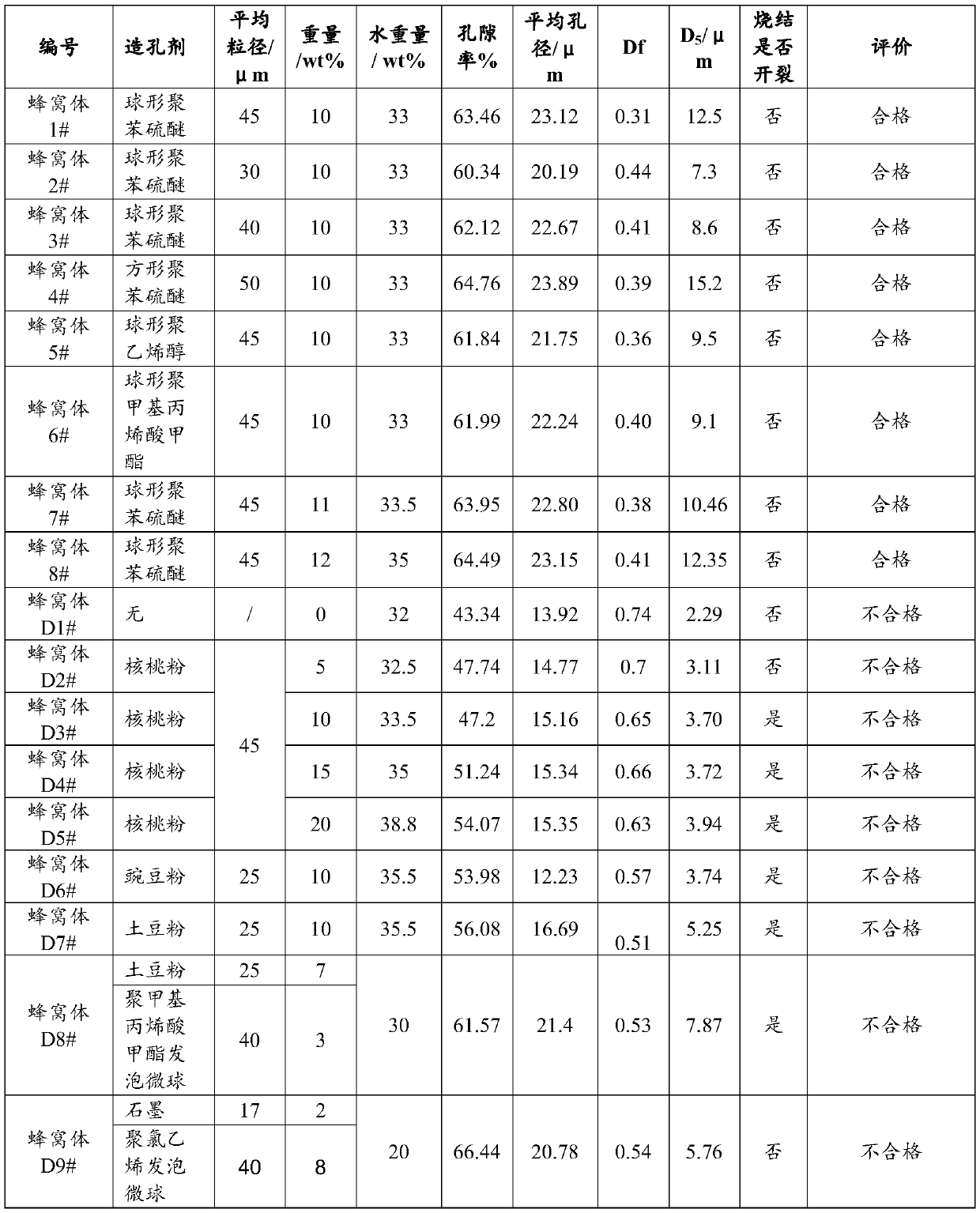

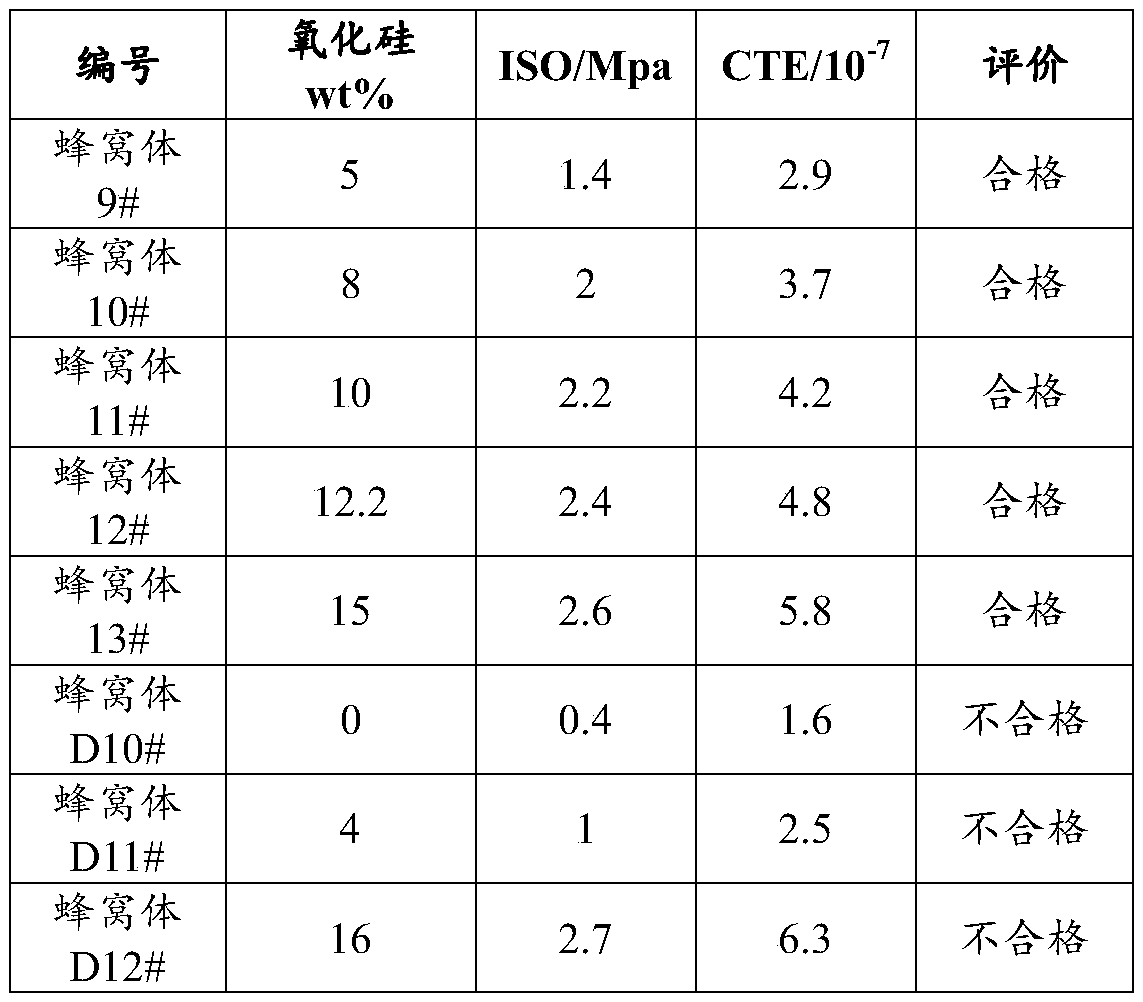

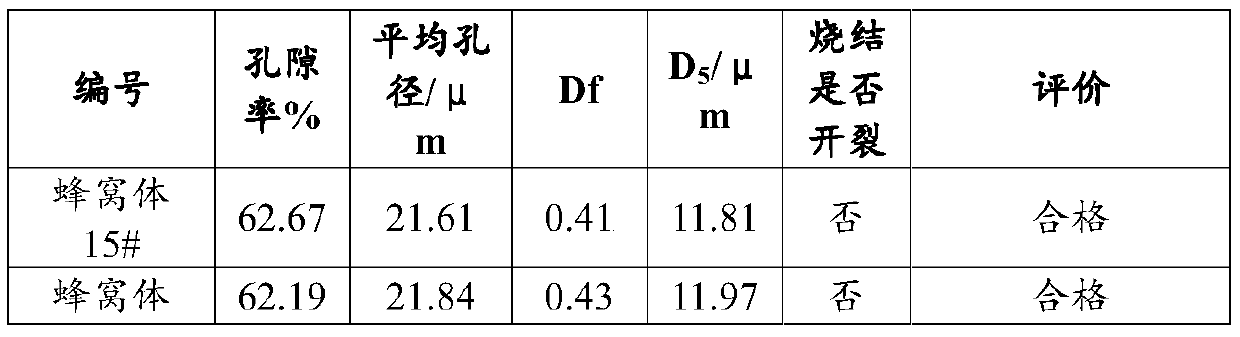

[0065] According to the preparation method of cordierite ceramic honeycomb body 1# in Example 1, cordierite ceramic honeycomb body 2#-8# and contrast cordierite ceramic honeycomb body D1#-D9# were prepared, which were the same as those of cordierite ceramic honeycomb body 1#. The method differences are shown in Table 1.

[0066] Comprehensively evaluate the pores and sintering cracks of the prepared cordierite ceramic honeycomb body 1#-8# and the comparison cordierite ceramic honeycomb body D1#-D9#, 60%≤porosity≤65%, 20μm≤average pore diameter≤24 μm, Df≤0.45, D5≥7μm, the sintered cordierite ceramic honeycomb body without cracking is evaluated as "qualified", and those that do not meet any of the above two evaluation criteria are considered "unqualified", among which, D 5 The corresponding pore volume accounts for 5% of the tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap