Curable silicone composition for light reflective material, cured silicone resin, reflector, and LED device

A technology of light-reflecting material and silicone composition, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult to form fine structures, lack of fluidity, high temperature, etc., and achieve excellent thermal stability and heat resistance. The effect of excellent discoloration and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095]

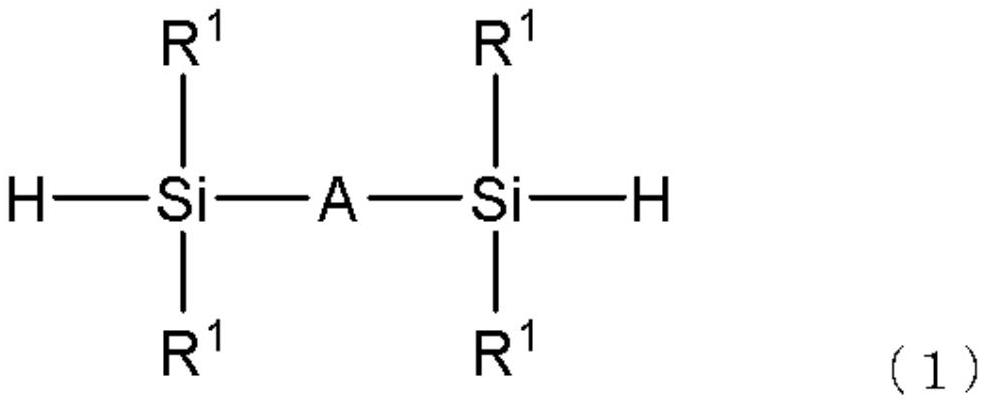

[0096] Component (A-1) of the curable silicone composition for light reflection materials of the present invention can be obtained as an addition reaction product having at least two addition-reactive carbon-carbon double bonds in one molecule and not having SiH , in the presence of a hydrosilylation reaction catalyst, 1 mole of the above-mentioned raw material (a) having 2 SiH in one molecule and more than 1 mole and 10 moles or less, preferably more than 1 mole and 5 moles or less It is obtained by addition-reacting the said raw material (b) which has two addition-reactive carbon-carbon double bonds in excess one molecule.

[0097] In addition to the addition-reactive carbon-carbon double bond derived from the raw material (b), the (A-1) component obtained in the above manner can also contain R 1 ) of the addition-reactive carbon-carbon double bond, so one molecule contains at least 2 addition-reactive carbon-carbon double bonds, the number of which is preferably...

Embodiment

[0193] Examples and comparative examples are shown below to describe the present invention in detail, but the present invention is not limited by the following examples. In addition, in the following examples, the viscosity is a value at 25° C. measured using a screw viscometer (manufactured by Malcom Co., Ltd., model: PC-1T) as a rotational viscometer.

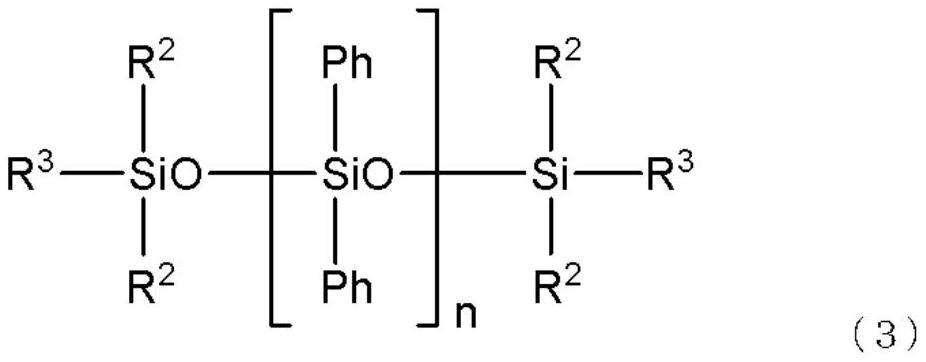

[0194] Symbols indicating the composition of silicone oil or silicone resin in the following examples are shown below. In addition, the number of moles of each silicone oil or each silicone resin represents the number of moles of vinyl groups or silicon atom-bonded hydrogen atoms contained in each component.

[0195] m H :(CH 3 ) 2 HSio 1 / 2

[0196] m Vi :(CH 2 =CH)(CH 3 ) 2 SiO 1 / 2

[0197] m ViΦ :(CH 2 =CH)(C 6 h 5 )(CH 3 ) SiO 1 / 2

[0198] D. H :(CH 3 )HSiO 2 / 2

[0199] D. Φ :(C 6 h 5 )(CH 3 ) SiO 2 / 2

[0200] D. 2Φ :(C 6 h 5 ) 2 SiO 2 / 2

Synthetic example 1

[0201] [Synthesis Example 1] Preparation of (A-1) Component

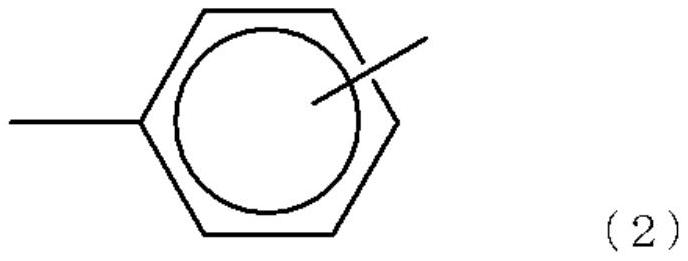

[0202] Add 1785 g (14.88 moles) of vinyl norbornene (trade name: V0062, manufactured by Tokyo Chemical Industry Co., Ltd.; 5- Vinylbicyclo[2.2.1]hept-2-ene and 6-vinylbicyclo[2.2.1]hept-2-ene isomer mixture in approximately equimolar amounts) and 455 g of toluene, using an oil bath Heat to 85°C. 3.6 g of carbon powder carrying 5% by mass of platinum was added thereto, and 1,698 g (8.75 mol) of 1,4-bis(dimethylsilyl)benzene was added dropwise over 180 minutes while stirring. After completion|finish of dripping, it heated and stirred at 110 degreeC for 24 hours, and cooled to room temperature after that. Then, platinum-supported carbon was removed by filtration, and toluene and excess vinylnorbornene were distilled off under reduced pressure to obtain 3362 g of a colorless and transparent oily reaction product (viscosity at 25° C.: 12820 mPa·s).

[0203] The reaction product was analyzed by FT-IR, NMR, GPC, etc., a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap