Resistor detection sorting device and detection sorting method

A resistance detection and sorting device technology, applied in sorting and other directions, can solve the problems of poor consistency of sorting quality, low labor efficiency, low resistance detection and sorting efficiency, etc., to improve detection efficiency and quality, and facilitate resistance value measurement. , the effect of facilitating the automation of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the prior art, in the detection of electronic components such as resistors, if a simple detection is performed, it is difficult to find quality problems such as resistance performance from the appearance alone. Deviations in subjective judgments lead to problems of quality consistency. To solve this problem, the following technical solutions are proposed:

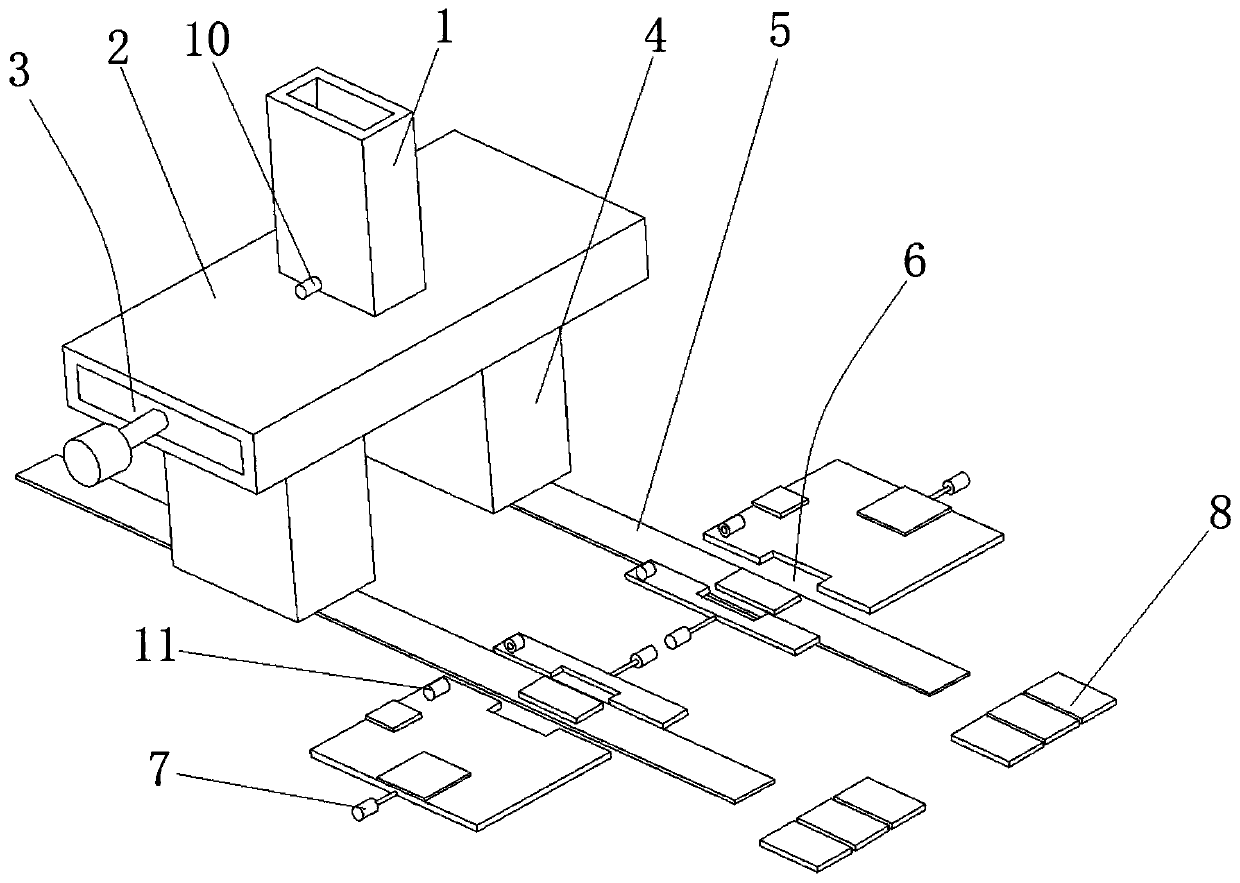

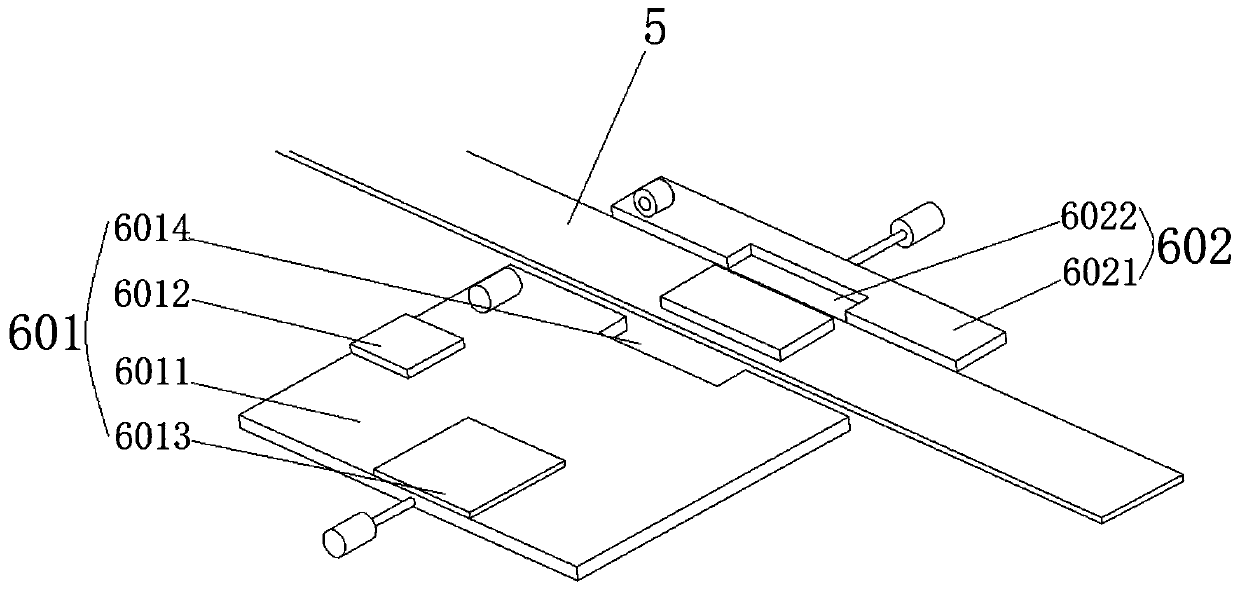

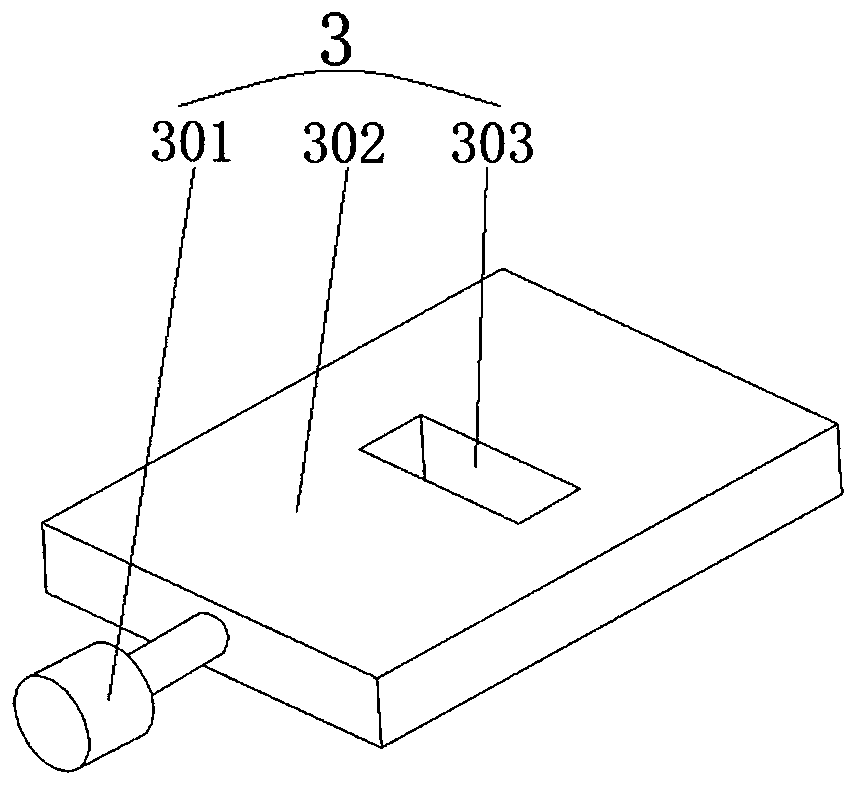

[0043] A resistance detection and sorting device, such as Figure 1-4, including a feed box 1, a separation box 2, a separation device 3, a blanking box 4, a conveyor belt 5, a detection platform 6, a push cylinder 7, a receiving car 8 and a PLC controller 9, and the lower end of the feed box 1 is provided with Separation box 2, and the lower end of the feed box 1 is connected with the separation box 2, and the resistance to be detected in the feed box 1 enters the separation box 2 for separation. Specifically, the separation box 2 is provided with a separation device 3. The lower end of the separation box 2 is ...

Embodiment 2

[0054] Using the resistance detection and sorting device as described above, this embodiment provides a resistance detection and sorting method, including the following steps:

[0055] The resistance to be detected existing in the feed box 1 falls into the separation box 2, and the resistance to be detected falls into the accommodation hole 303 of the separation block 302;

[0056] The separation block 302 slides under the drive of the reciprocating cylinder 301, and the resistance to be detected in the accommodation hole 303 falls downward into the blanking box 4;

[0057] The resistor to be detected drops downward from the drop box 4 on the conveyor belt 5, and the conveyor belt 5 transports the resistor to be detected to the end of the conveyor belt 5;

[0058] The resistance to be detected is transmitted forward on the conveyor belt 5 and contacts the photoelectric switch 11, the detection platform 6 moves and clamps the resistance to be detected, and the detection platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com