A kind of multi-head fabric laser cutting equipment and cutting method

A laser cutting, laser cutting head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of yellowing of broken velvet, low cost, yellowing of fabrics, etc., to reduce yellowing and fluff. The effect of reducing the amount of lint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

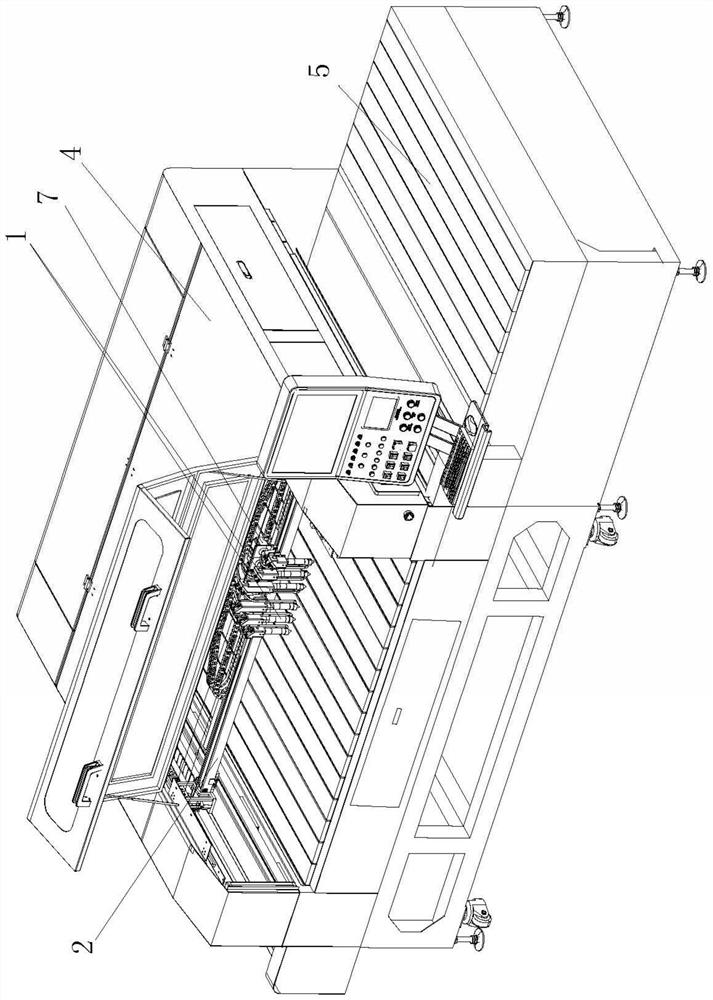

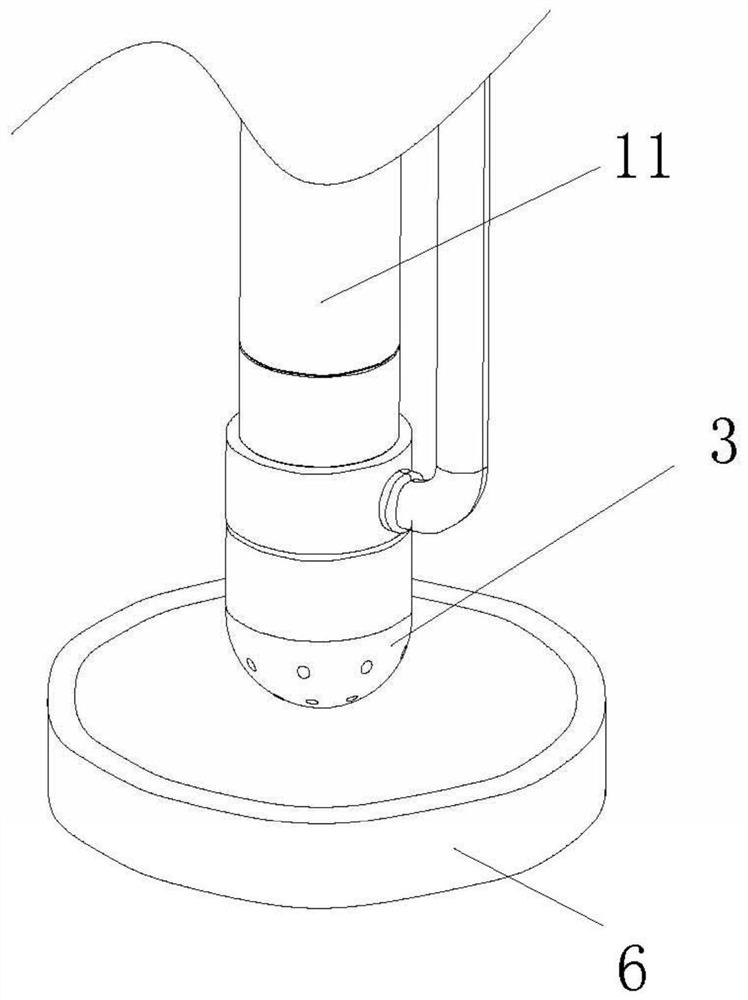

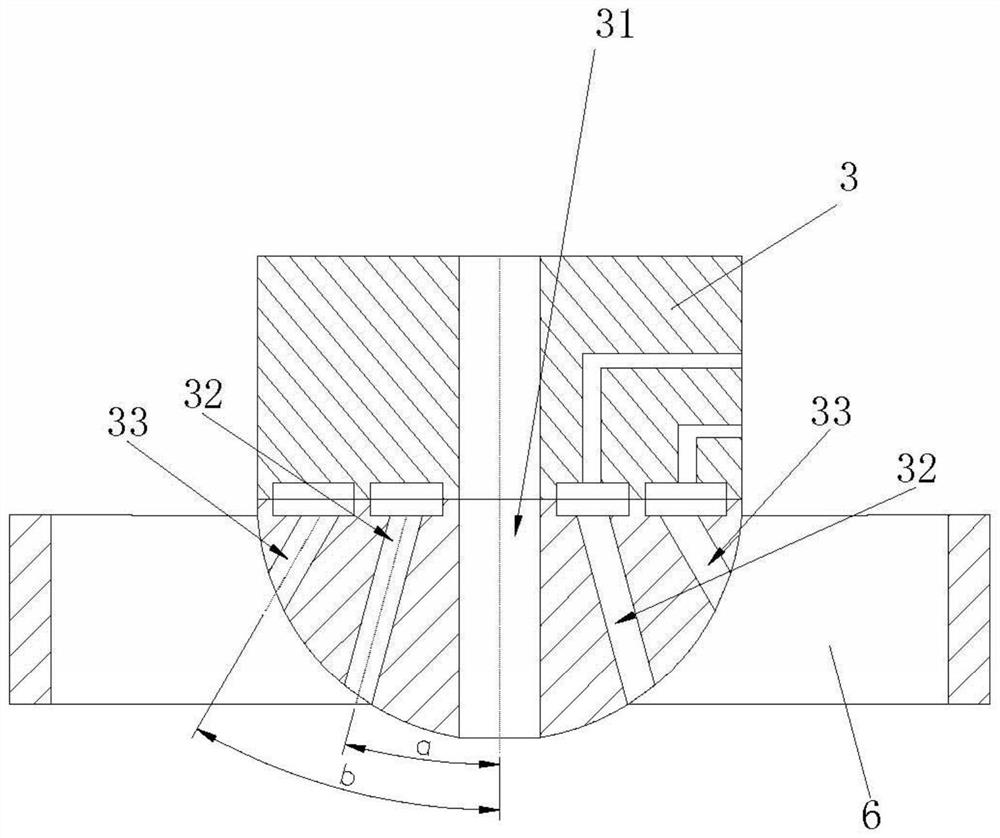

[0030] Such as Figure 1~3 As shown, a kind of multi-head cloth laser cutting equipment of the present invention comprises feed inlet, discharge outlet, shielding cover 4, frame, laser generator, transmission network chain 5, laser cutting head 1, described shielding cover 4, The laser generator is installed on the frame; the laser cutting head 1 includes a housing 11, a reflective mirror, a focusing mirror, and a laser nozzle, the reflective mirror is obliquely arranged on the top of the housing 11, and the focusing mirror is arranged on the shell The lower part of the body 11, the focusing mirror is located directly below the reflector, the laser nozzle is arranged at the lower end of the housing 11, and the side of the laser nozzle is provided with an air inlet; it also includes a sliding beam 2, an electrostatic generator and a blowing nozzle 3; The laser nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com