A coal pushing device for fuel transportation in thermal power plants

A technology for thermal power plants and fuels, which is used in transportation and packaging, conveyors, loading/unloading, etc., and can solve the problems of coal lumps sliding, incomplete structure, and imperfect coal lumps gathering and surrounding structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

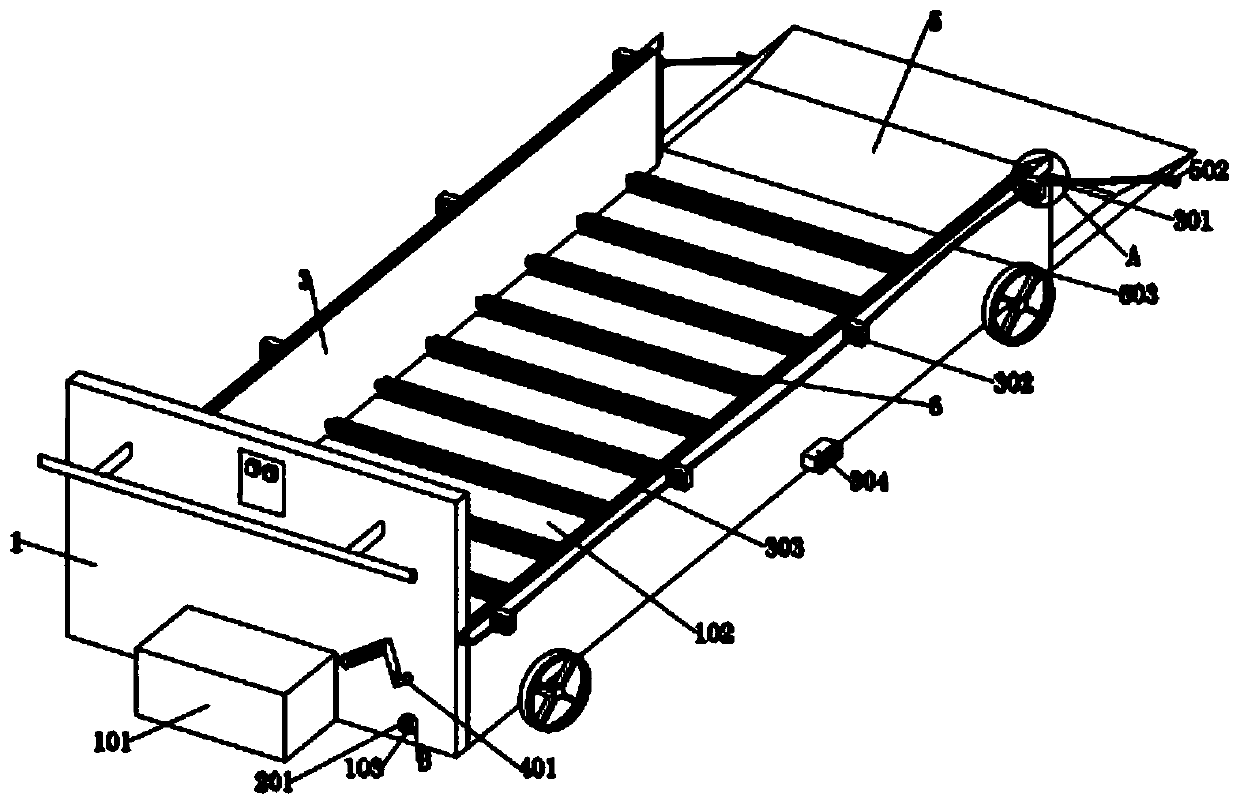

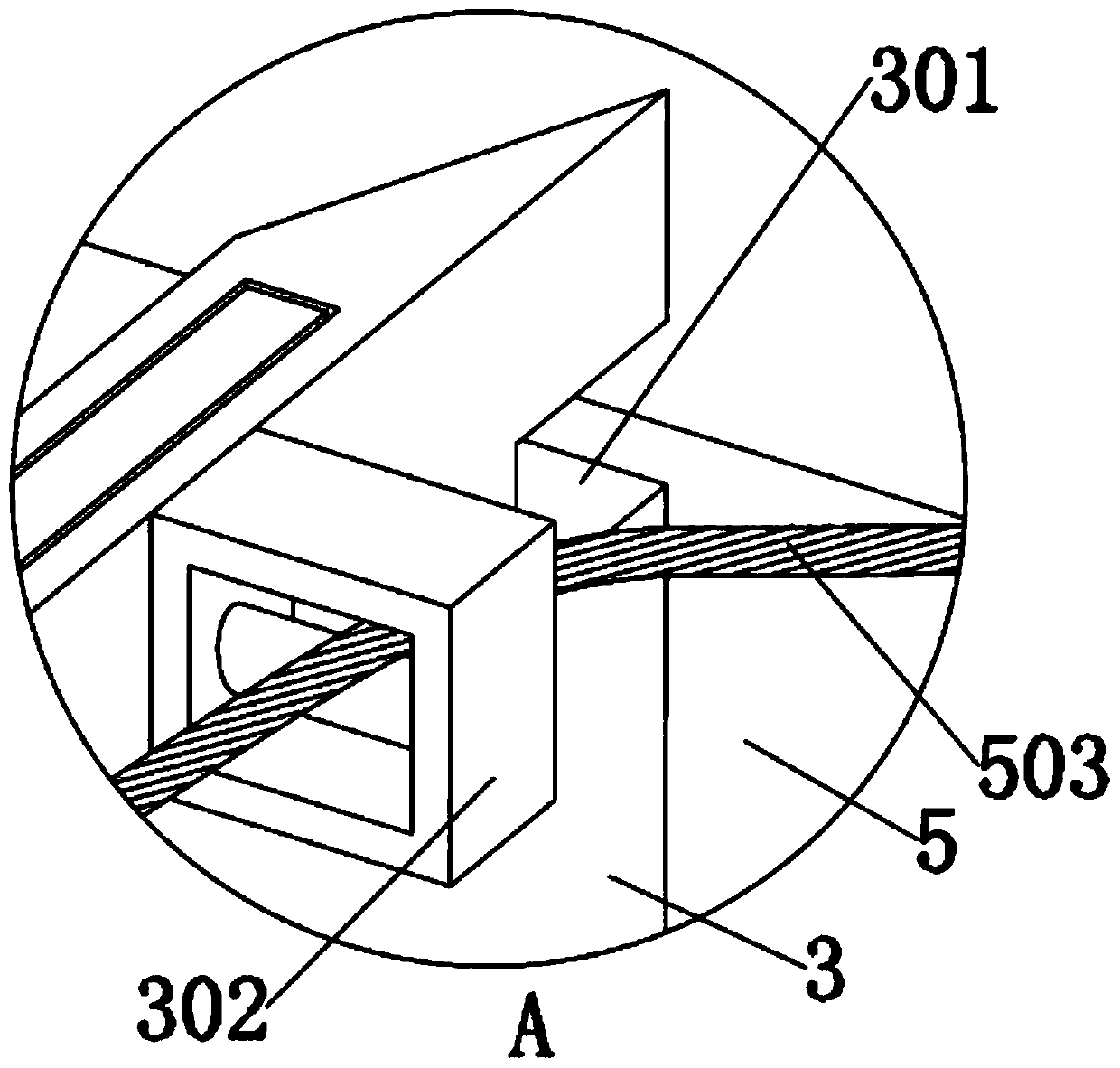

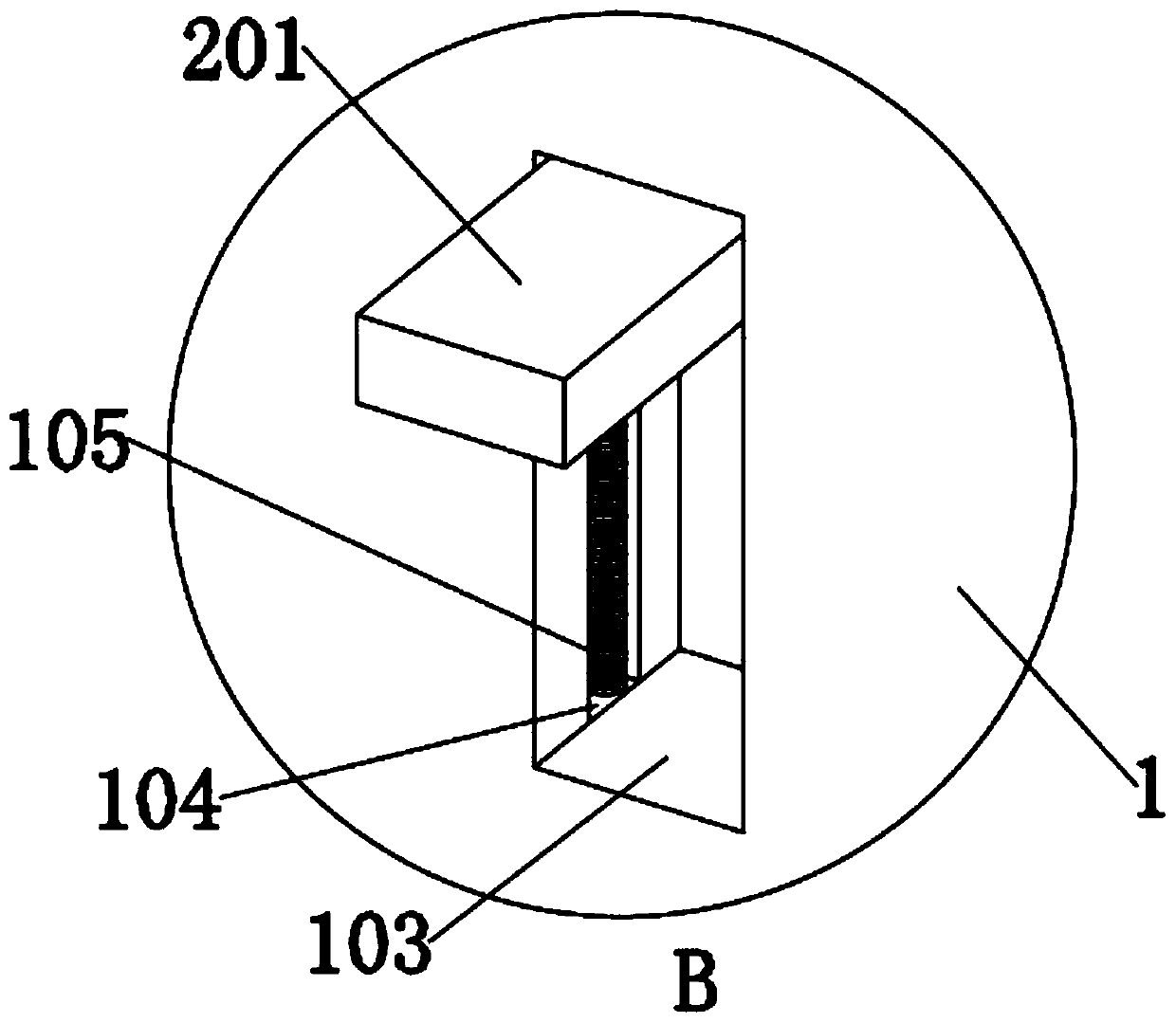

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031]The present invention provides a coal pushing device for fuel transportation in thermal power plants, which includes: a main body 1, a motor cover 101, a bottom plate 102, a moving groove 103, a mounting groove 104, a supporting spring 105, a sliding block 2, a force plate 201, a card Part 202, side plate 3, bayonet 301, guide 302, moving plate 303, moving block 304, chuck 305, rotating part 4, hand part 401, limit part 402, front plate 5, pulley 501, connecting part 502, a traction rope 503, a rotating rod 6, a contact piece 601 and an anti-slip strip 602; the main body 1 is a rectangular plate structure, and a push rod is installed above the front end of the main body 1 by welding, and the middle of the front bottom of the main body 1 The position is provided with a motor cover 101, and the inside of the motor cover 101 is provided with a motor and a battery, and the motor is connected to the shaft of the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com