System and method used to produce lubricating oil base oil and high melting point Fischer-Tropsch wax

A technology of lubricating base oil and Fischer-Tropsch wax, which is applied in the field of coal chemical industry, can solve the problems of single production product, waste of raw materials, and no consideration of long carbon chain Fischer-Tropsch synthetic wax.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

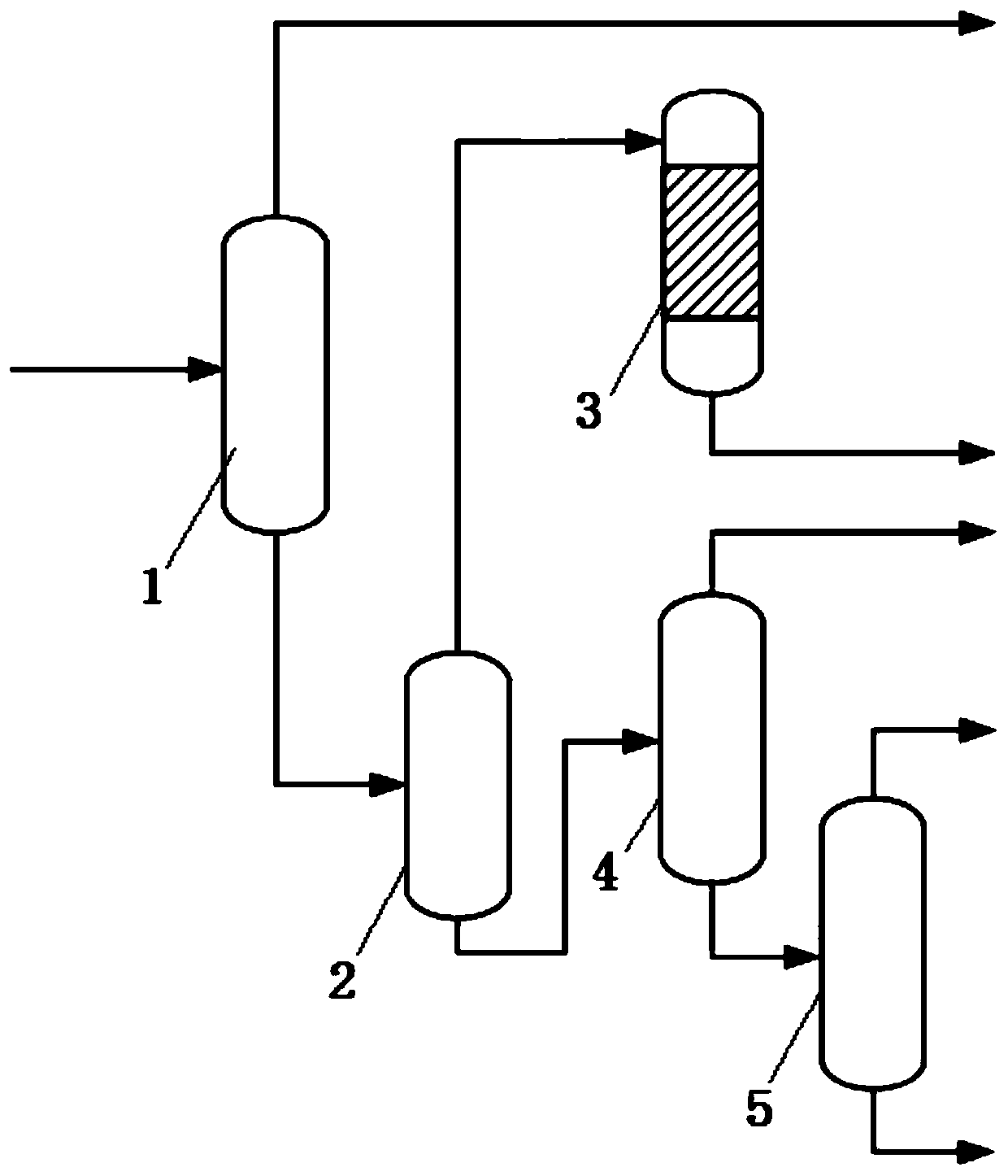

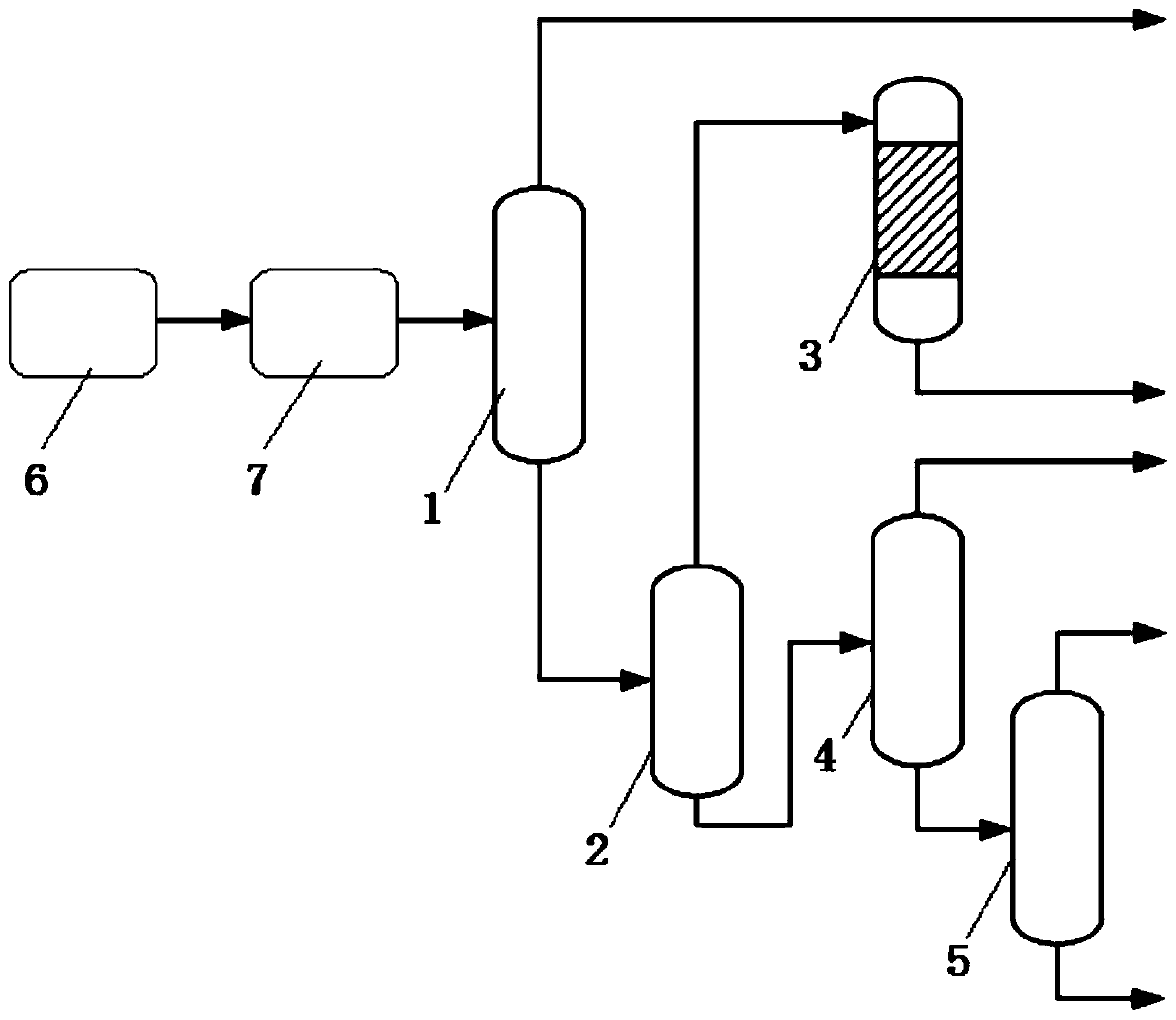

Method used

Image

Examples

Embodiment 1

[0111] Utilize the system and method for producing lubricating oil base oil and high melting point Fischer-Tropsch wax of the present invention to produce lubricating oil base oil and high melting point Fischer-Tropsch wax, obtain lubricating oil base oil, middle melting point Fischer-Tropsch wax (medium melting point Fischer-Tropsch wax) That is, the first Fischer-Tropsch wax fraction with a melting point of less than 80°C) and high-melting Fischer-Tropsch wax (the high-melting Fischer-Tropsch wax includes the third Fischer-Tropsch wax fraction with a melting point of 80-105°C and the fourth Fischer-Tropsch wax with a melting point greater than 105°C fraction). in,

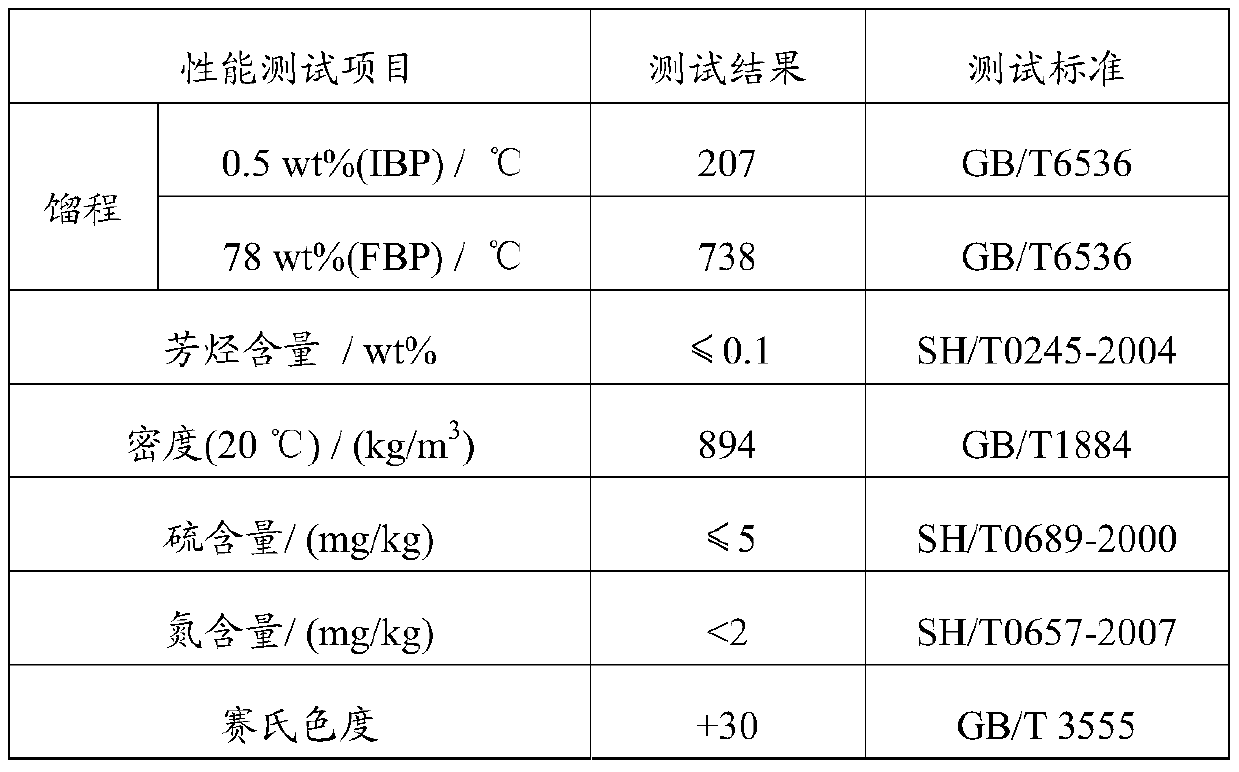

[0112] (1) The specific properties of Fischer-Tropsch hydrotreated oil as raw material are shown in Table 1.

[0113] Table 1 Properties of Fischer-Tropsch hydrorefined oil

[0114]

[0115] (2) The operating conditions are as follows:

[0116] The first vacuum distillation tower 1, the operating temperatur...

Embodiment 2

[0134] Using the Fischer-Tropsch hydrotreated oil in Example 1 as the raw material, the operating conditions of the first vacuum distillation column 1 and the second vacuum distillation column 2 are the same as in Example 1.

[0135] Isomerization dewaxing reactor 3 is a fixed bed reactor, which is filled with the catalyst used for hydroisomerization reaction, and the volume space velocity of the reaction is 1.0h -1 ; The hydroisomerization reaction in the isomerization dewaxing reactor 3, the reaction temperature is 350 ℃, the reaction pressure is 3.2MPa, the hydrogen oil volume ratio is 600:1; the catalyst used comprises the following steps:

[0136] (1) Take PtCl with a molar ratio of 4:1 2 and PdCl 2 , drop a hydrochloric acid solution with a temperature of 45°C and a concentration of 30wt% into the PtCl 2 and PdCl 2 in, until PtCl 2 and PdCl 2 Completely dissolved to obtain a PtCl-containing 2 and PdCl 2 hydrochloric acid solution;

[0137] (2) at room temperature a...

Embodiment 3

[0147] With the Fischer-Tropsch hydrorefined oil in embodiment 1 as raw material, the first vacuum distillation tower 1, the second vacuum distillation tower 2 operating conditions are identical with embodiment 1;

[0148] For the hydroisomerization reaction in the isomerization dewaxing reactor 3, the reaction conditions and the catalyst used are the same as in Example 1, and the main properties of the obtained lubricating oil base oil are the same as those of the lubricating oil base oil obtained in Example 1. The main properties are the same.

[0149] The third vacuum distillation tower 4 and the fourth vacuum distillation tower 5 are wiped-film molecular distillation towers; the operating temperature of the third vacuum distillation tower 4 is 280°C, the operating pressure is 40Pa, and the wiped film speed is 350r / min; The operating temperature of the fourth vacuum distillation tower 5 is 280 ° C, the operating pressure is 40 Pa, and the film scraping speed is 350 r / min; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap